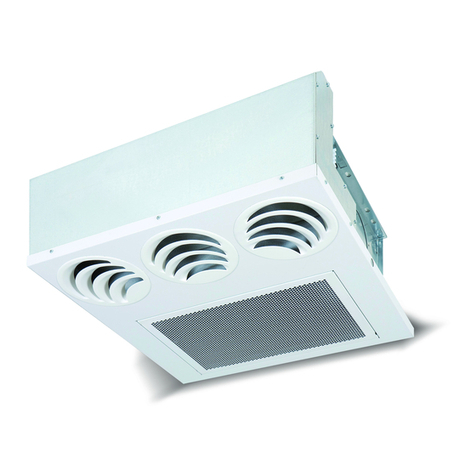

User's and Maintenance Manual CEILING FAN

1 - INTRODUCTION

1.1 General warnings

-

Make sure you have a complete copy of this manual and the enclosed Assembly Instructions available. Read

both documents fully and make sure you understand them adequately before proceeding with subsequent steps.

If you have any doubt about a task to be carried out, apply the criterion of maximum personal and collective

safety. Immediately interrupt your work, make everything done so far in complete safety, and ask for adequate

instructions, if necessary, from the manufacturer as well.

-

Check the integrity of the equipment when opening the packaging. Pay particular attention to damage to or

deformation of mechanical parts, which may result in breakage and/or malfunctions when in use. If any of these

are found, do not connect the machine to the power supply. Carry out these checks every time before use.

-

Before connecting the machine to the power supply, check that the indications on the data plate correspond to

the electricity supply. The data plate is located on the electronic motor (see par. 1.9).

- Each and every person that may come into contact in any way with the product marketed by EVEL s.r.l.,

and described here, must be adequately informed by the purchaser of about use, risks, dangers and

safety procedures, in the ways provided for by law and as described below in this document.

-

Conform to the safety norms indicated for electrical equipment, and especially:

o

Conform to the assembly and installation instructions for the equipment.

o

Do not put items on top of the ceiling fan, and do not hang anything from the ceiling fan's blades.

o

Do not allow children and/or incapable or untrained personnel to use the device or go near it without the

necessary supervision.

o

Adequately train employees on use of the machine and risks associated with its use.

o

Do not touch the ceiling fan when it is running, or immediately after it has stopped. Remember that the

motor could be hot.

o

Never immerse the equipment in water or any other liquid, and do not use water, especially pressurised,

for washing or cleaning the fan or its parts. This equipment is not designed to be impermeable to water.

Do not touch the equipment if it gets wet by accident. Immediately disconnect the power supply by

switching off the switch on the electrical panel for the your system, and immediately disconnect the

feeder before touching the equipment. Use suitable means to indicate that reinstating the power supply

at the panel is forbidden.

o

o

Do not touch the equipment with wet and/or damp hands.

o

Do not use accessories, spare parts and/or components that are not indicated or supplied by the

manufacturer.

o

Do not pull the power supply cable or expose it to a risk of being sheared.

o

If a fault occurs and/or the equipment works badly, switch it off immediately and disconnect the power

supply. Use suitable means to indicate that reinstating the power supply at the panel is forbidden. Do

not attempt to open or tamper with the equipment. Contact Evel's technical service department.

1.2 Warnings for correct disposal of the product

In terms of European Directive 2002/96/EC.

At the end of its working life, the product must not be disposed of with urban waste.

It can be taken to specific separated collection centres set up by the municipality, or to dealers who provide this

service. Disposing of the product separately makes it possible to avoid negative consequences for the

environment and for health, resulting from inadequate disposal, and it also makes it possible to recycle the

materials of which it is made, in order to achieve significant savings in terms of energy and resources.

1.3 Conventions used in this manual

The Manual is broken down into independent chapters, each of which is addressed to a specific type of operator

(INSTALLER, MACHINE OPERATOR AND MAINTENANCE TECHNICIAN), for which the skills required to

operate on the machine in safety have been defined.

The sequence of the chapters follows the temporal logic of the machine's lifespan.

page 3