3. Working area

ARBPRO LD1 is designed and manufactured only for tree care operations, to lower branches and

limbs during pruning and rigging operations.

It must be attached at the base of a tree with correct dimensions and enough strength to complete

the job. User must be trained and must be sure that the tree has enough strenght to support

forces generated by rigging operations

4. Rigging rope

ARBPRO LD1 must be used only in combination with high quality textile ropes. In no

circumstances can be used with metal wire ropes.

Use of double braided polyester ropes is recommended in the dimensions written in this manual.

Always check rigging gear before using it. User must check rope conditions and be sure of rope

strength. In case of any doubt on rope conditions, replace it with a new one.

Rope size depends on the installed application. Following rules must be respected:

- ARBPRO LD1 with winch installed: rope diameter must be 1 or 14 mm (½ or 9/16”)

- ARBPRO LD1 with descending brakeinstalled: rope diameter must be 1 , 14 or 16 mm (½, 9/16

or 5/8”)

5. Installation

ARBPRO LD1 can be installed on the same tree where the job will be done or on a different tree.

User must be sure that the tree is strong enough.

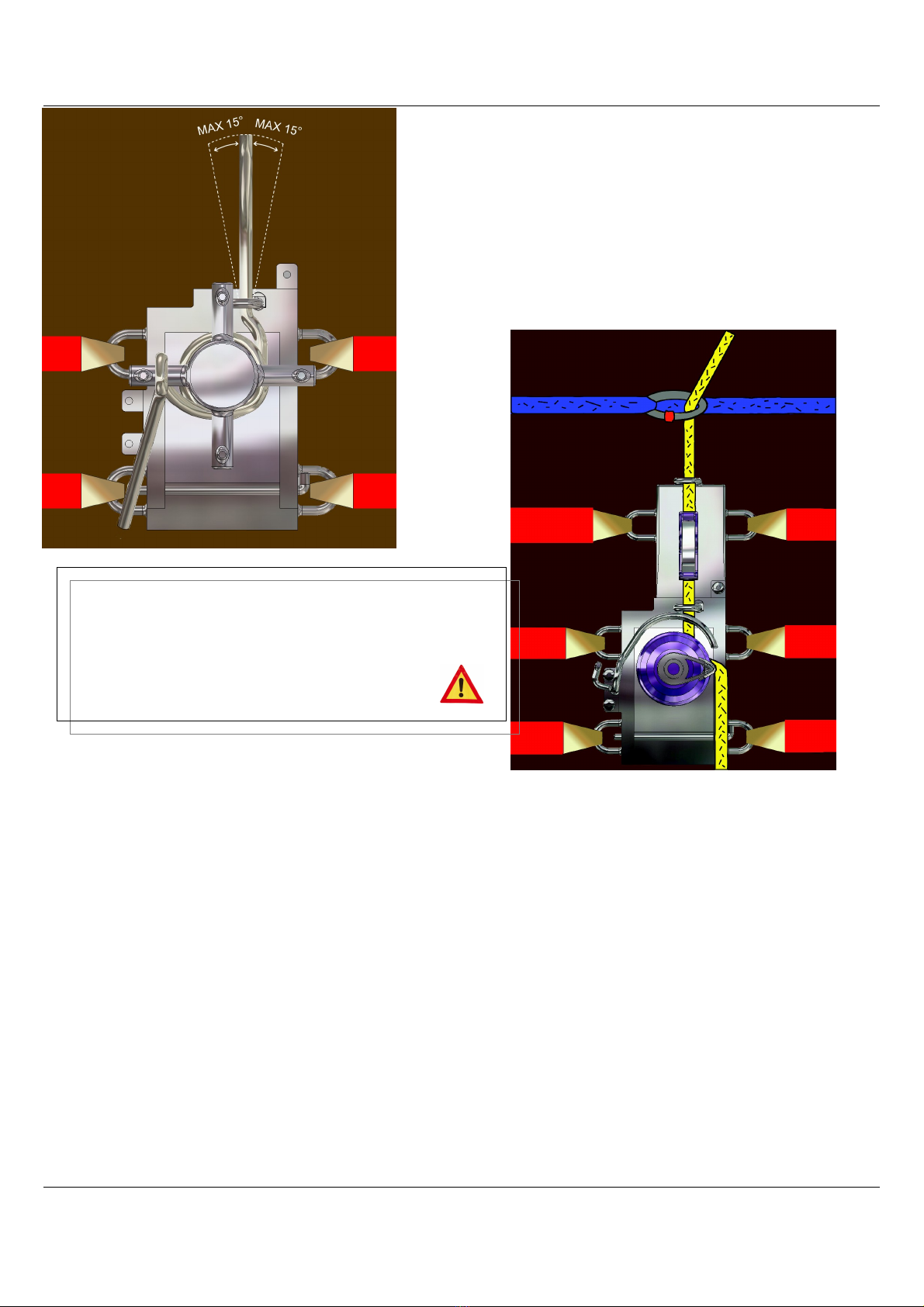

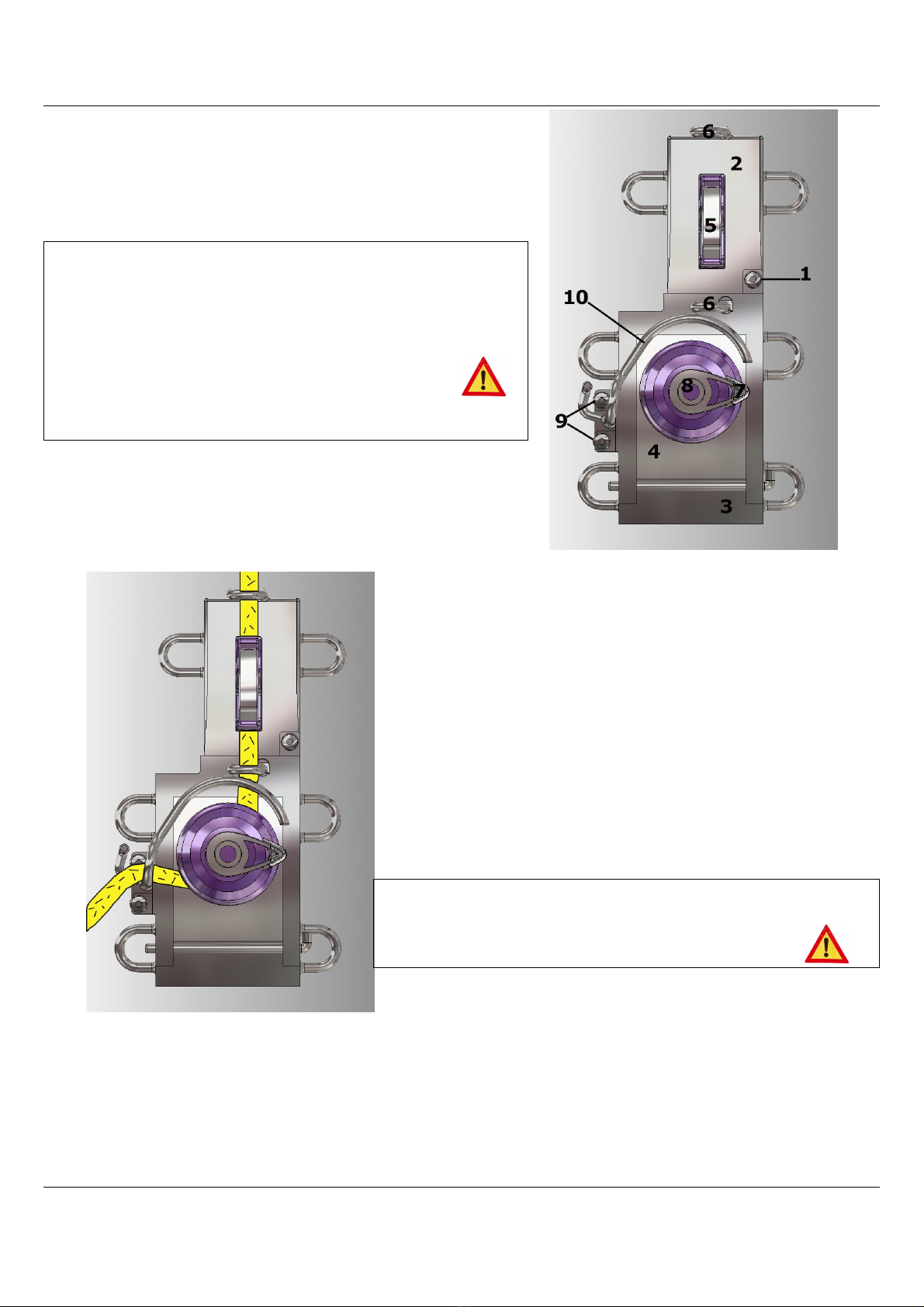

Two different types of installation are possible:

-”Light” this installation is recommended if the tree must be preserved. For this installation rubber

pads (6) must be mounted in the slots on back of the main frame.

Safe working load with this type of installation is

kg 800 (with oth winch or decending rake

installed)

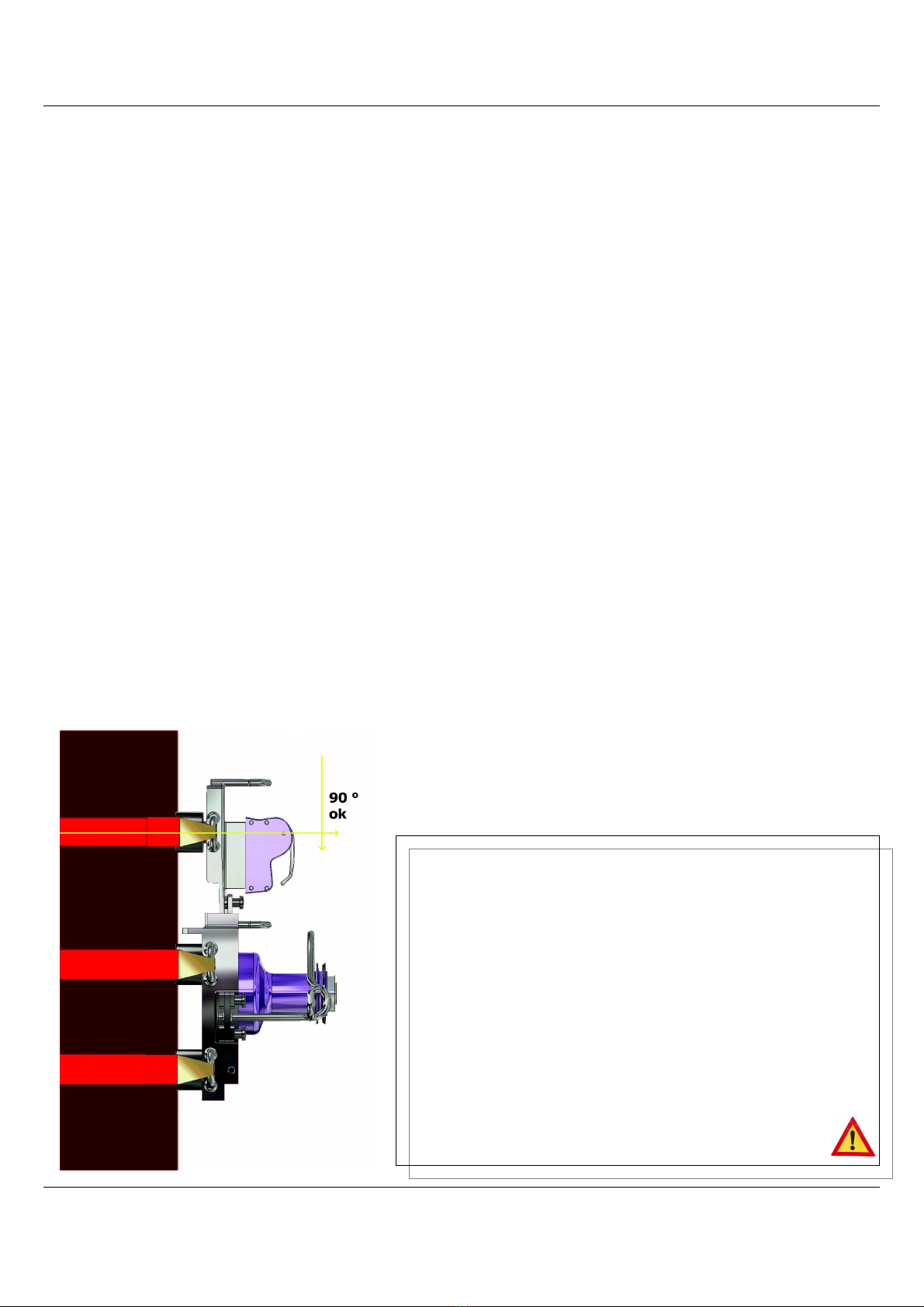

Straps assem ly (in all kind of installation):

Check straps before installation.

Install straps by inserting the hooks into the rings

placed on side of main frame (Attention! Ratched bar

should be mounted facing outside). Straps must be

at 90°. Any other angle in not correct and potentially

dangerous.

Tighten straps by pulling on ratched bar to reach a

good anchorage.

Fig. 4

Page 4