5

Introduction

WARNING Any procedure, which not properly followed, may cause injury

to the operator or others in the operating area�

WARNING Carefully read this manual regarding rules for user safety before

installing, operating, or servicing the equipment�

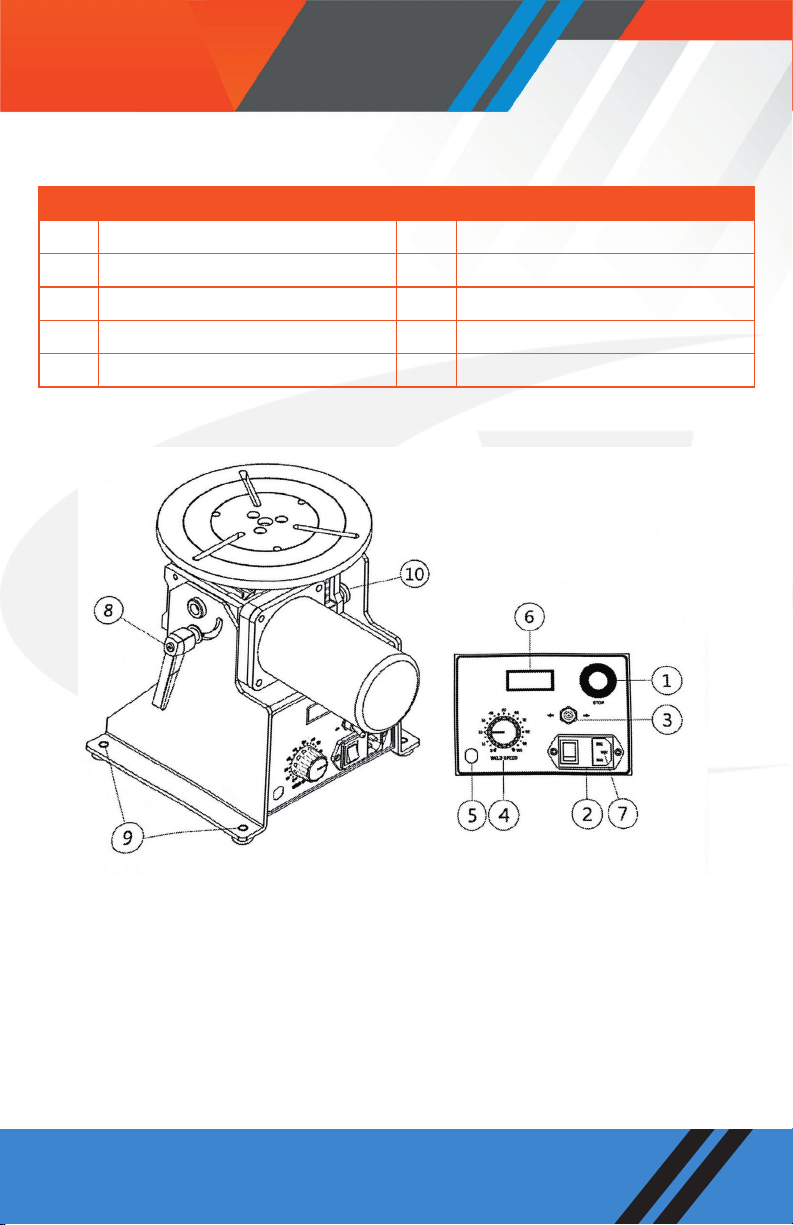

Equipment identification The identification number, model, and serial number of this unit can

be found on a nameplate attached to the control panel� Please record

these numbers for future reference�

Receipt of equipment Upon receiving the equipment, please check the shipping list� Make

sure it is complete and inspect the equipment for possible damage

during shipping� If there is any damage, notify the carrier immediately

to file a claim.

Safety Precautions

WARNING

Please be warned that operation and maintenance of the system

involve potential hazards� All operators and personnel should take

precautions to prevent possible injury�

Electrical safety Machine

•The counter, safety device against excess current and electrical

installation, are compatible with its maximum power and its main

voltage�

•The connection, single-phase or three-phase, is possible on a

stand compatible with the plug of its cable link�

•If the cable is connected with the electrical network, the earth

must never be cut by the protection device against electrical

shocks�

Work Place

•Avoid contact between metal part and phase conductor and the

neutral of electric network�

•Electrical messes of different electrical machine and apparatus

are connected between themselves and with the terminal of earth

neutral wire�

Interventions

•Before control and repair

, see the apparatus is switched off and

insulated�

•Connection with fixed installation cable is impossible.

•It’s on “Stop” and connection is impossible�

•Some apparatus areprovided with starting circuit HTHF(with a plate)�

Never enter into the corresponding switch cupboard�

•Only qualified persons are authorized for intervention concerning

electrical installation

Maintenance •Often check the insulation and connection good state of apparatus

and electrical accessories: taps, appliance cords, coatings, switch,

extension cords, etc�

• Maintenance and repair of insulating coatings operations are very

•important�

• Do repair with a specialist or better replace defective accessories�

•Check regularly the right adjustment and the non-heating of

electrical connections�