^o`JwlkbK`ljI=fåÅ. z==OMVN=i~ë=m~äã~ë=aêáîÉ=píÉK=` z==`~êäëÄ~ÇI=`^==VOMNNJNRRN=

qÉäW=TSMKVPNKNRMM z==UMMKVQQKOOQP z==c~ñW=TSMKVPNKNRMQ z==bJj~áäW=áåÑç]~êÅJòçåÉKÅçã==

ïïïK~êÅJòçåÉKÅçã=

=

Copyright 2007, Arc-Zone.com®, Inc. All Rights Reserved.

NJUMMJVQQJOOQP=

ïïïK~êÅJòçåÉKÅçã=

=

máê~åÜ~=fff=léÉê~íáçåë=j~åì~äW=m~ÖÉ=Q=

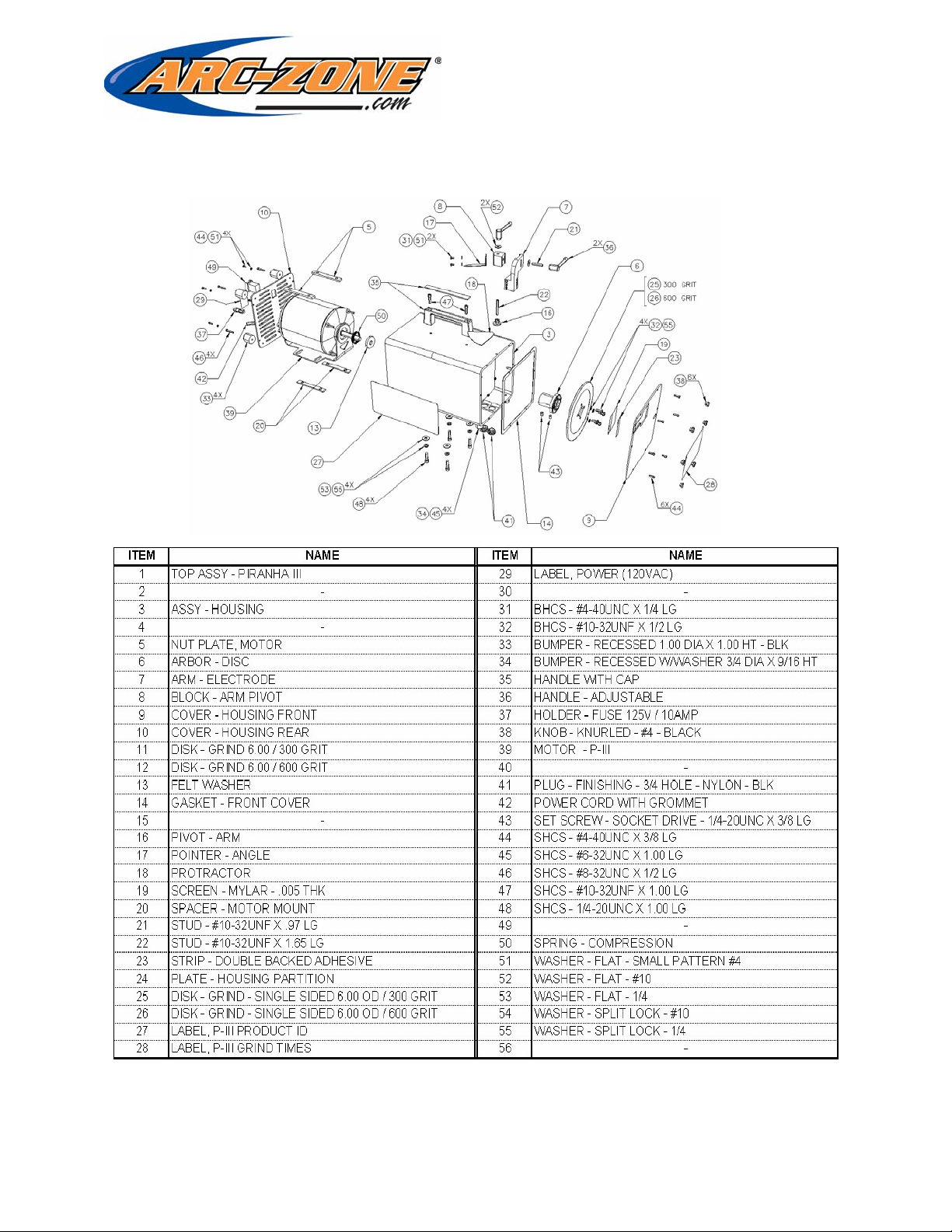

The Piranha 3 Heavy-duty Precision grinding machine allows operators to diamond

grind electrodes consistently and accurately for improved weld quality and increased

productivity. Precision ground electrodes deliver extended arctime, minimized arc

wander, electrode spitting, shedding and weld inclusions.

SPECIFICATIONS:

Motor: ¼ HP- 3000 RPM - 2.5 Amps – 115 Volts @ 60 HZ

Optional 220Volt, 50/60 Hz motor available, specify when ordering.

Grinding Wheels: Single sided diamond impregnated: Available in 300, for

electrodes from 3/32” (2.4mm) to 3/16” (4.8mm) and 600 grit, for electrodes from .040

(1.0mm) to 1/16” (1.6mm)

Weight: 38lbs. (83.6kg)

WARRANTY:

The Piranha 3 Heavy-duty Precision Tungsten Grinder from Arc-Zone.com comes with

a one-year parts and labor warranty (excluding diamond wheel). This warranty

excludes “excessive” abuse or improper handling. Note: This is a precision machine

and should be treated accordingly.

SAFETY INFORMATION: Read Safety Precautions Carefully.

Note: This Precision Machine Is Designed To Grind Tungsten Electrodes Only!

• When not grinding electrodes, turn grinder off for safety purposes decreased wear

on the precision electric motor.

• Wear proper safety apparel. Do not wear loose clothing, neckties, rings, bracelets,

or other jewelry, which may get caught in the machine.

• Wear safety glasses and face mask.

• Never operate power tools when tired, intoxicated, or when taking medication that

cause drowsiness.

• Use a grounded three-prong-plug, and plug directly into a three-prong-outlet.

• Keep visitors a safe distance from work area.

• Always unplug grinder prior to inspection.

• Read this manual thoroughly for specific adjustments and operating procedures.

• To ensure consistent electrode preparation, replace damaged parts.