4

Contents

Thank you 2

SAFETY 2

Item check list 3

Installation process 5

Wheel Install 6

Wheel Install continued 7

Battery Cradle Installation 9

Battery Cradle Installation continued 10

Throttles and grips 11

Display 11

E-brake sensors 12

Controller 13

Controller continued 14

Removable Pedal Assist Sensor (RPAS) 15

RPAS Continued... 16

Battery Operation 17

Charging 18

Maintenance and Care 19

Trouble Shooting 20

Trouble Shooting Continued... 21

Trouble Shooting Continued... 22

Trouble Shooting Continued... 23

Specications 24

Before you start your conversion, you will have

to decide if you’re installing the battery on the

down tube (recommended) or on the provided

rear rack. You will also have to decide if you

are going to install a throttle (you can run the

system using just the pedal assist sensor) and

which of the two throttle options is going to

work best with your bike.

Most commonly the thumb throttle is preferred,

as it leaves more room on your handlebars for

other components. Using the thumb throttle

means you can even use your current grips

if you prefer, leaving your handlebars almost

untouched.

One of the many benets of the ARC kits is the

exibility in the installation.

Once you have decided on the ideal conversion

for your bike, it’s time to prepare the bike.

Start by checking over each component and

familiarize yourself with the terminology. A

common mistake is when people refer to the

LCD display as the ‘controller’. The LCD functions

as a readout for the conversion kit. The

controller is actually the rectangular box which

houses the major control components of the

electric system.

Once you have looked over the parts to

familiarize yourself, remove the grips from your

current bikes (if installing a throttle) and turn the

bike upside down so it rests on the seat and the

ends of the handlebars (if you don’t have a bike

stand). Take the rear wheel out and deate and

remove the tire, tube and rim tape. Install these

onto the new electric wheel.

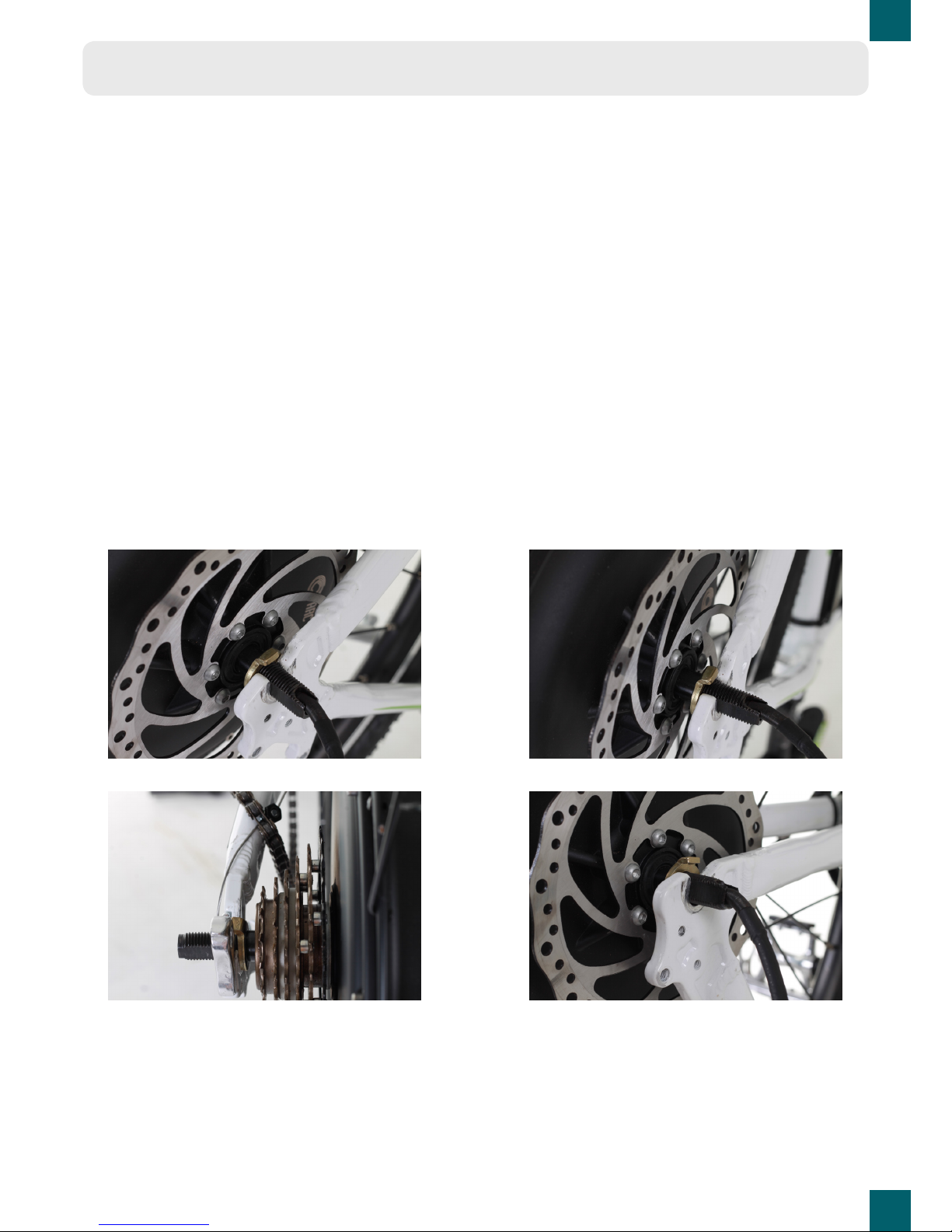

If you’re installing disk brakes, it’s ideal to

remove the caliper which will make it easier to

install the rear wheel.