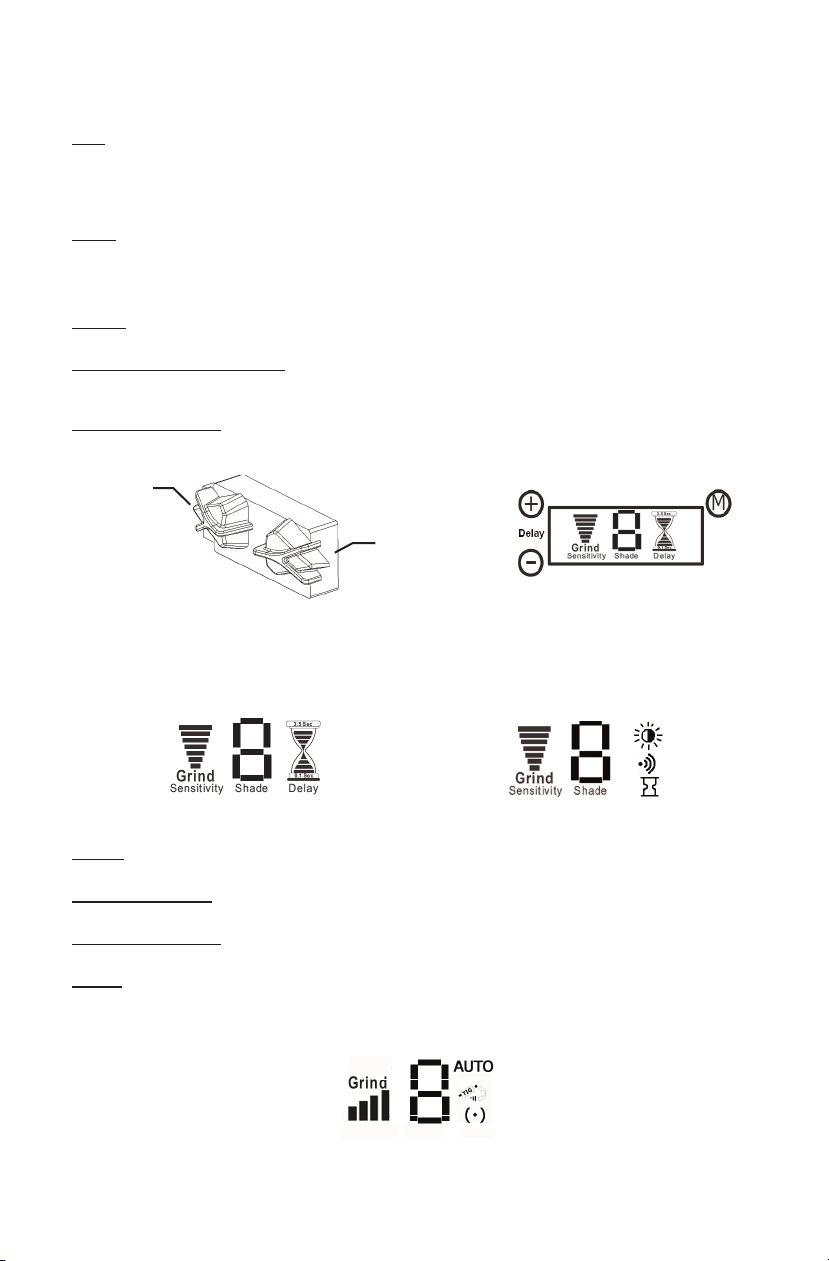

Intelligent Darkening Filter (iDF) Modes

The iDF-48 has three modes of operation: Standard, Auto-Variable, and iTIG. Switch modes by

Pressing AND Holding down the “ ” mode button until the desired mode icon is flashing.

Auto-Variable Mode: LCD displays “AUTO” (see Figure 3). Filter automatically responds to the

intensity of the welding arc and sets the filter to the appropriate dark shade. The user can further

adjust the dark shade up or down for comfort while the “(٠)” flashes. The setting will be saved in a

memory slot. This mode has 8 memory slots, one for each shade number 7 thru 14; i.e. shade 7 =

memory 1, shade 8 = memory 2, etc. The user can reset all memory slots by Pressing and Holding

both ode and Delay buttons for two seconds.

iTIG Mode: LCD displays “TIG” icon (see Figure 3). While the “(٠)” flashes, the user first sets the

lower desired shade. After approximately five seconds of not turning the shade knob the flashing stops

and the user can then set the desired upper shade. The user can reset memory by Pressing and

Holding both ode and Delay buttons for two seconds.

Care and Maintenance

Your new filter requires virtually no maintenance other than periodic cleaning when lens becomes dirty or

clouded from smoke.

ArcOne

®Auto-Darkening Filters are water-resistant and may be cleaned by using a

soft cloth with soapy water solution, or standard window cleaner. Welding helmet may be cleaned with soft

cloth and soapy water. Do not submerge filter or welding helmet in water or solution. Store in original or

similar packaging and store in a safe dry place away from direct heat between 14 - 100°F (-10 - 38°C).

iDF-48: The battery located in the external control center will last 3-6 months depending on usage.

Replace with AA battery of same voltage (1.5 V).

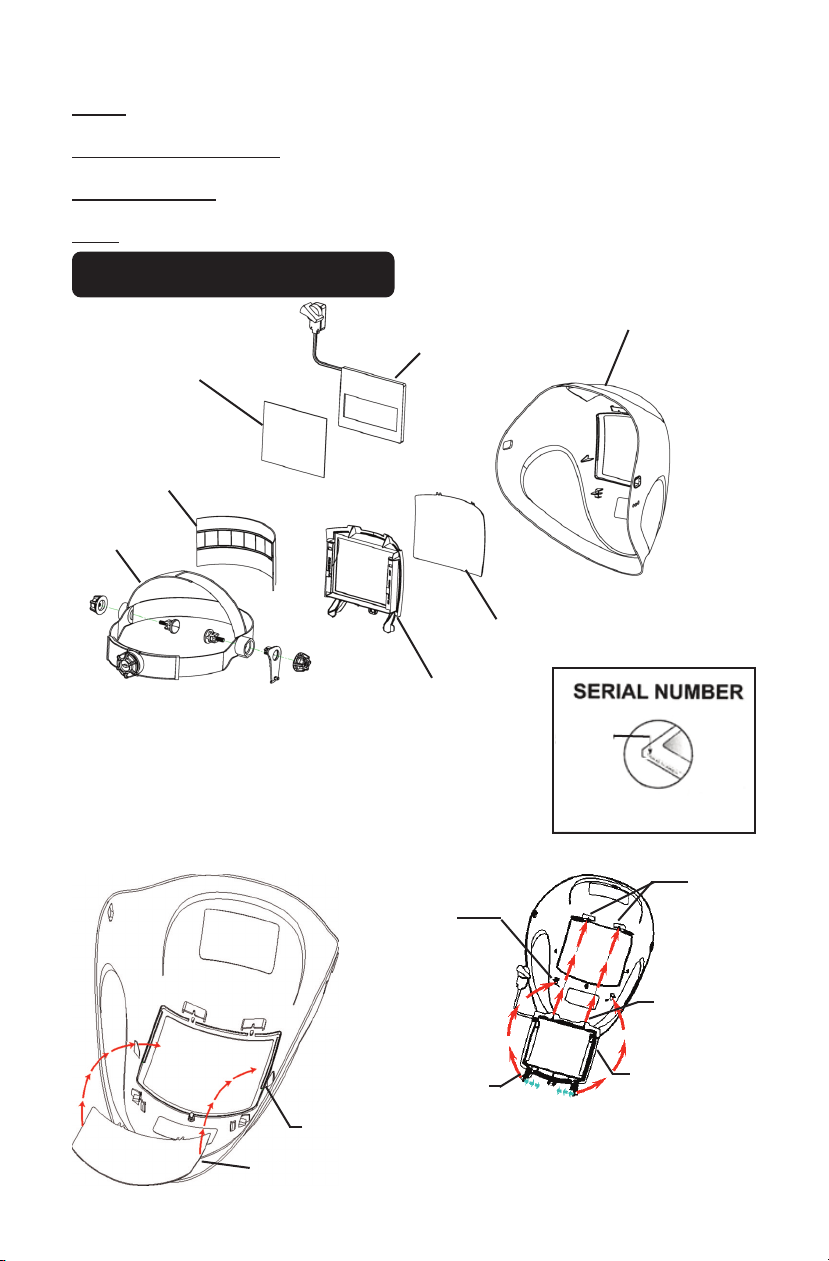

WARNING! Using the wrong cover plates may damage your product, compromise UV/IR protection,

and VOID WARRANTY. Use genuine

ArcOne

®replacement parts to ensure quality and fit.

NOTE: Change your cover plate when it loses its flexibility and/or becomes bowed or distorted.

Clean any build-up from the area where the cover plate is retained.

ake sure there is no damage to the filter or helmet shell including, but not limited to cracks, holes,

and melting. Do not use if damaged. Contact your distributor for replacement parts. Use only

replacement components as specified for each welding helmet in accordance with this user manual.

PATTER DAMAGE I NOT COVERED BY WARRANTY

LIMITED WARRANTY

ArcOne

®warrants all digital Auto-Darkening filters listed in this manual for three (3) years and all

non-digital Auto-Darkening filters for two (2) years against all manufacturing defects resulting from

materials or workmanship from the date of purchase. Proof of purchase establishing the date of sale and

filter serial number must be provided, should a warranty claim be submitted. The purchaser’s only

remedy under this limited warranty shall be limited to

ArcOne

®sole operation to repair, replace or

refund (not to exceed the purchase price). This limited warranty is not transferable from the original

purchaser to a secondary owner.

ArcOne

®shall in no event be liable or responsible for any injury,

damage or loss resulting either directly or indirectly from the use or misuse of this product. This limited

warranty is exclusive and is in lieu of any other warranty implied either oral or written. Please read the

instruction manual carefully to avoid certain situations which may void this limited warranty.

In the unlikely event that the Auto-Darkening filter malfunctions, the following procedures are to be

used to receive efficient service and repair: Determine if the product is damaged from abuse or

misuse. Any pitted marks on the filter possibly from spatter, chips, dents, or cracks, etc., are some

indications of operator abuse. In the case of operator abuse the warranty is void.

RETURN PROCEDURE

1. Remove the Auto-Darkening filter from the helmet. Record the model number and serial number

which are located on the filter edge or back. Also record the date of purchase from your sales receipt.

2. Contact

ArcOne

®Technical Support (800-223-4685) for a Return Tag Number and further

instructions.

ArcOne

®is a Division of A.C.E. International Company

85 Independence Drive, Taunton, A 02780

TEL: (508) 884-9600 • TOLL FREE: (800) 223-4685

FAX: (508) 884-9666

Visit our website and register at:

www.arc1weldsafe.com