291

291

291

292

293

295

297

297

297

298

298

298

301

301

305

305

309

309

312

314

315

316

318

319

320

321

323

324

324

327

327

327

327

327

329

329

329

329

330

331

331

332

332

332

333

334

334

335

335

335

335

335

335

336

337

338

339

340

341

6.1. Communication protocols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.1. NTP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.2. ModbusTCP and ModbusRTU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.3. ModbusIO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.4. IEC 61850 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.5. GOOSE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.6. IEC 103 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.7. DNP3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.8. IEC 101/104 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.9. SPA protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2. General IO analog fault registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3. Real time measurements to communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7. Applications and connection examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1. Connections AQ-T257 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2. Example 2 winding transformerprotection connection . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3. Trip circuit supervision (95) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8. Construction and installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1. Construction and installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2. CPU, IO and Power supply module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3. Current measurement module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4. Voltage measurement module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.5. Binary input module (DI8) (option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.6. Binary output module (DO5) (option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.7. Arc protection module (option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.8. RTD & mA input module (option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.9. Serial RS232 communication module (option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.10. LC100 Ethernet communication module (option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.11. mAout & mAinput module (option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.12. Installation dimensioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9. Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1. Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1.1. Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1.1.1. Power and energy measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1.1.2. Current measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1.1.3. Voltage measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1.1.4. Frequency measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1.2. CPU & Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1.2.1. Auxiliary voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1.2.2. CPU communication ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1.2.3. CPU Binary inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1.2.4. CPU Binary outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1.3. Option cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1.3.1. Binaryinput module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1.3.2. Binary output module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1.3.3. Arc protection module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1.3.4. mAout & mAin module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1.3.5. RTD & mA input module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1.3.6. RS232 & Serial ber communication module . . . . . . . . . . . . . . . . . . . . . .

9.1.3.7. Double LC100Mb Ethernet module(Redundant) . . . . . . . . . . . . . . . . . . .

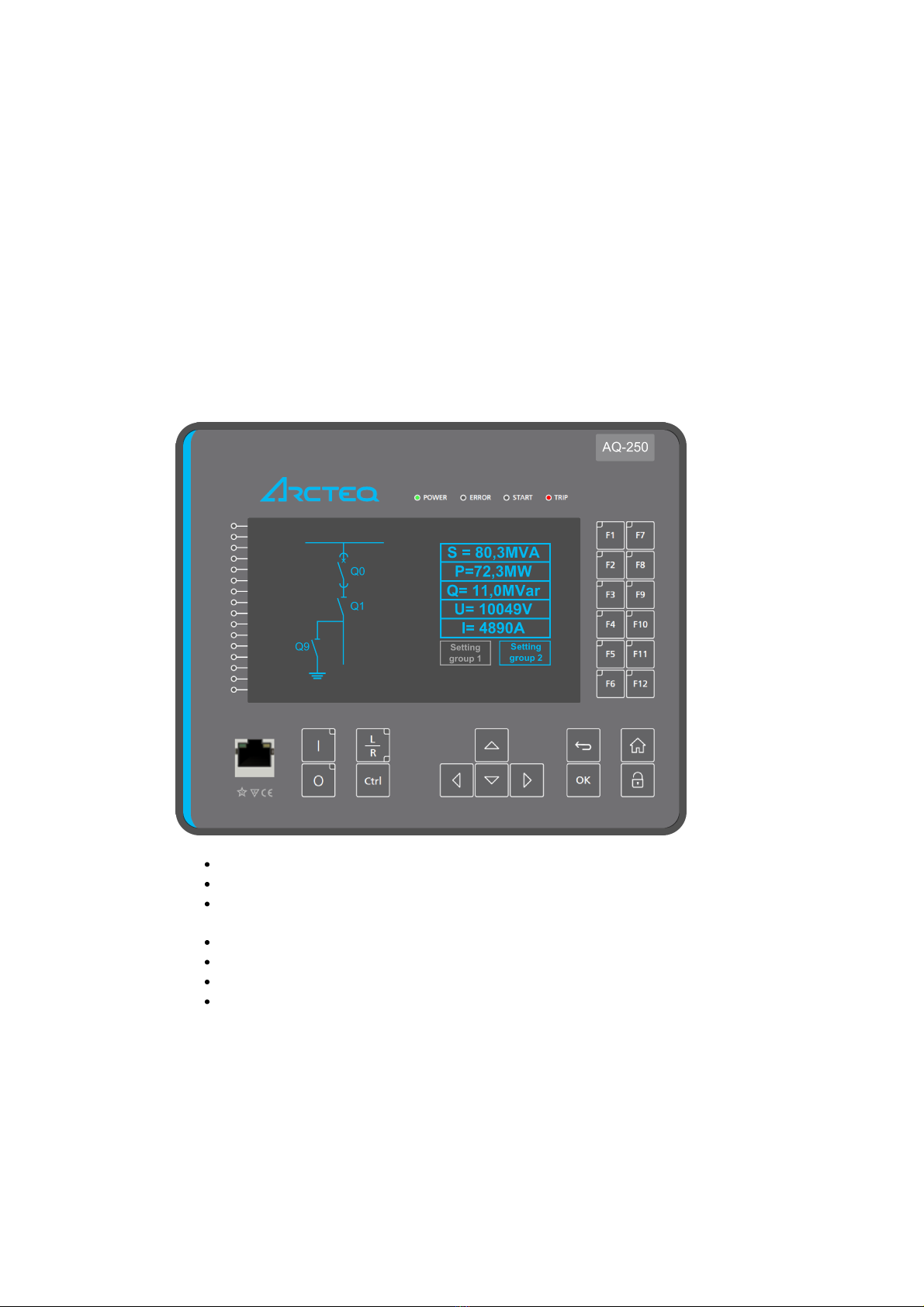

9.1.4. Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2. Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2.1. Protection functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2.1.1. Non-directional overcurrent (50/51) I> . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2.1.2. Non-directional earth fault (50N/51N) I0> . . . . . . . . . . . . . . . . . . . . . . . .

9.2.1.3. Directional overcurrent (67) Idir> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2.1.4. Directional earth fault(67N) Iodir> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2.1.5. Current unbalance (46/46R/46L) I2> . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2.1.6. Harmonic overcurrent (50H/51H, 68) Ih> . . . . . . . . . . . . . . . . . . . . . . . .

9.2.1.7. Circuit breaker failure protection (50BF/52BF) CBFP . . . . . . . . . . . . . . .

AQ-T257

Instruction manual

Version: 2.00