AQ-1000 Instruction Manual - 1.3 EN.docx Page | 4

© Arcteq ltd

Table of Contents

Disclaimer.................................................................................................................................................................................. 3

Copyright.................................................................................................................................................................................. 3

1 Safety Precautions................................................................................................................................................................... 5

2 Installation.............................................................................................................................................................................. 6

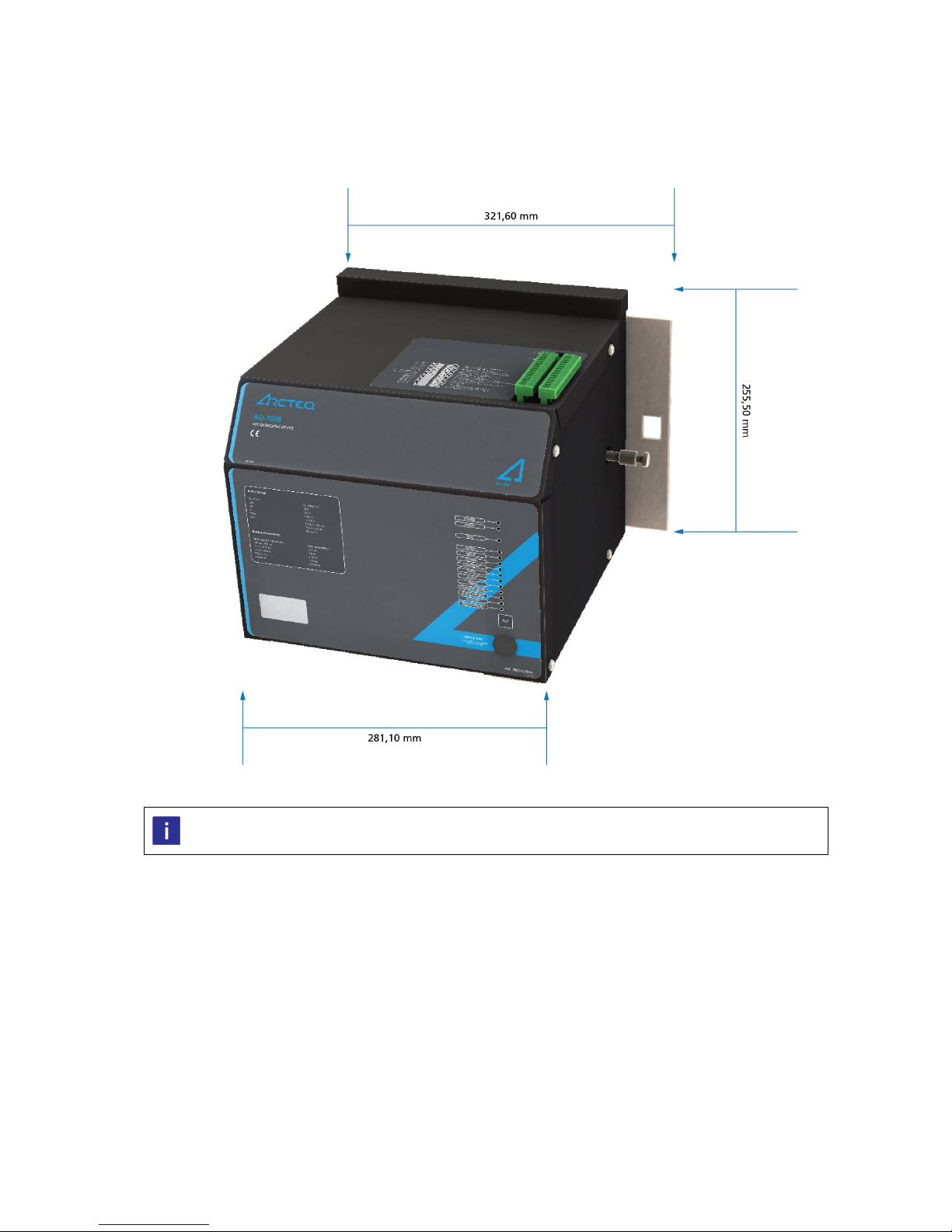

2.1 Device dimensions ......................................................................................................................................................... 6

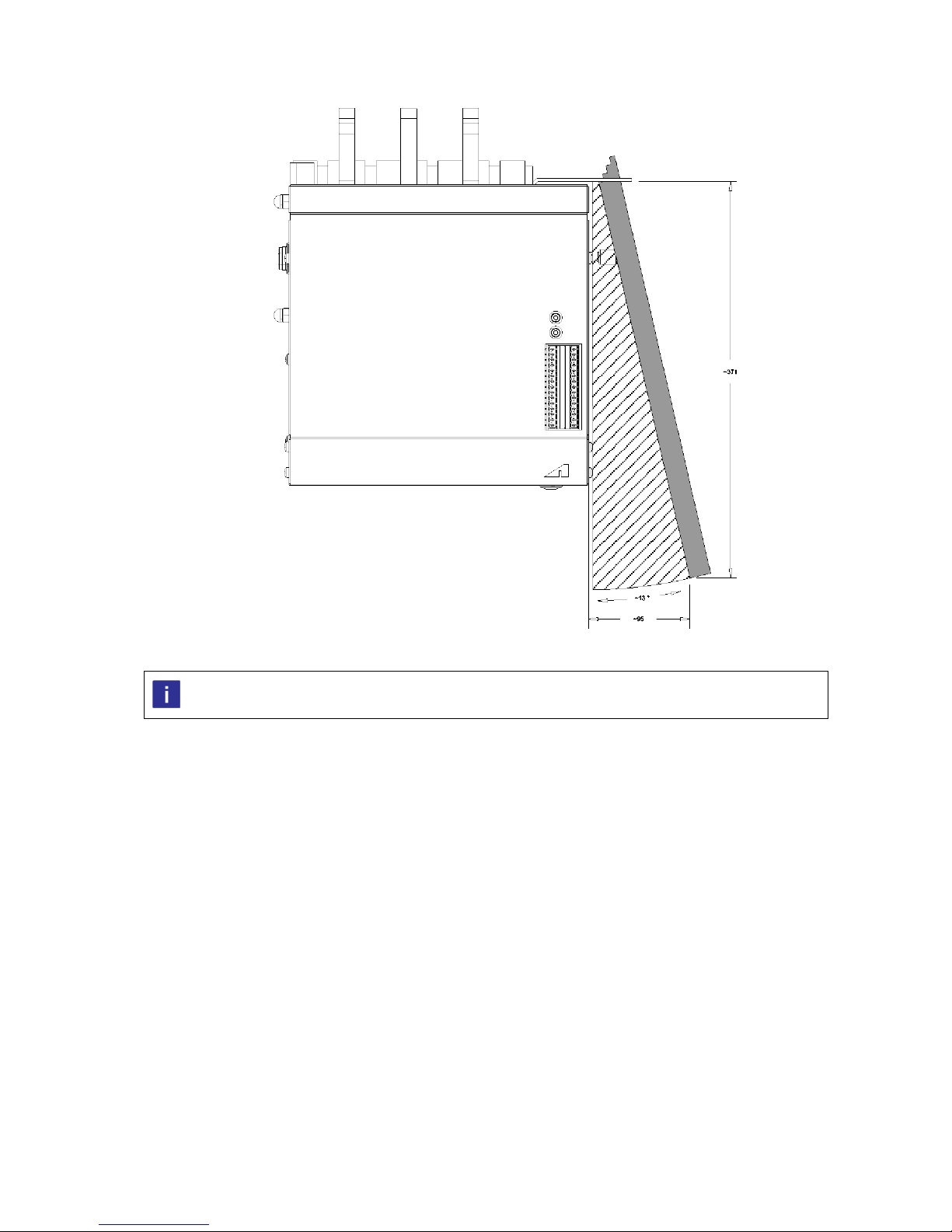

2.2 Mechanical installation................................................................................................................................................. 12

2.3 Wiring......................................................................................................................................................................... 15

2.4 Device Grounding........................................................................................................................................................ 16

3 Operation............................................................................................................................................................................. 17

3.1 Operating modes......................................................................................................................................................... 17

3.2 LED Indicators.............................................................................................................................................................. 18

3.3 Binary Input Functions ................................................................................................................................................. 19

3.4 SET Button .................................................................................................................................................................. 19

3.4 Self-supervision functions............................................................................................................................................. 19

3.5 Restoring quenching device contacts ............................................................................................................................ 20

4 Commissioning..................................................................................................................................................................... 21

5 Application Example ............................................................................................................................................................. 22

6 Technical data ...................................................................................................................................................................... 24

7 Order Code .......................................................................................................................................................................... 27

Contact information ................................................................................................................................................................ 28