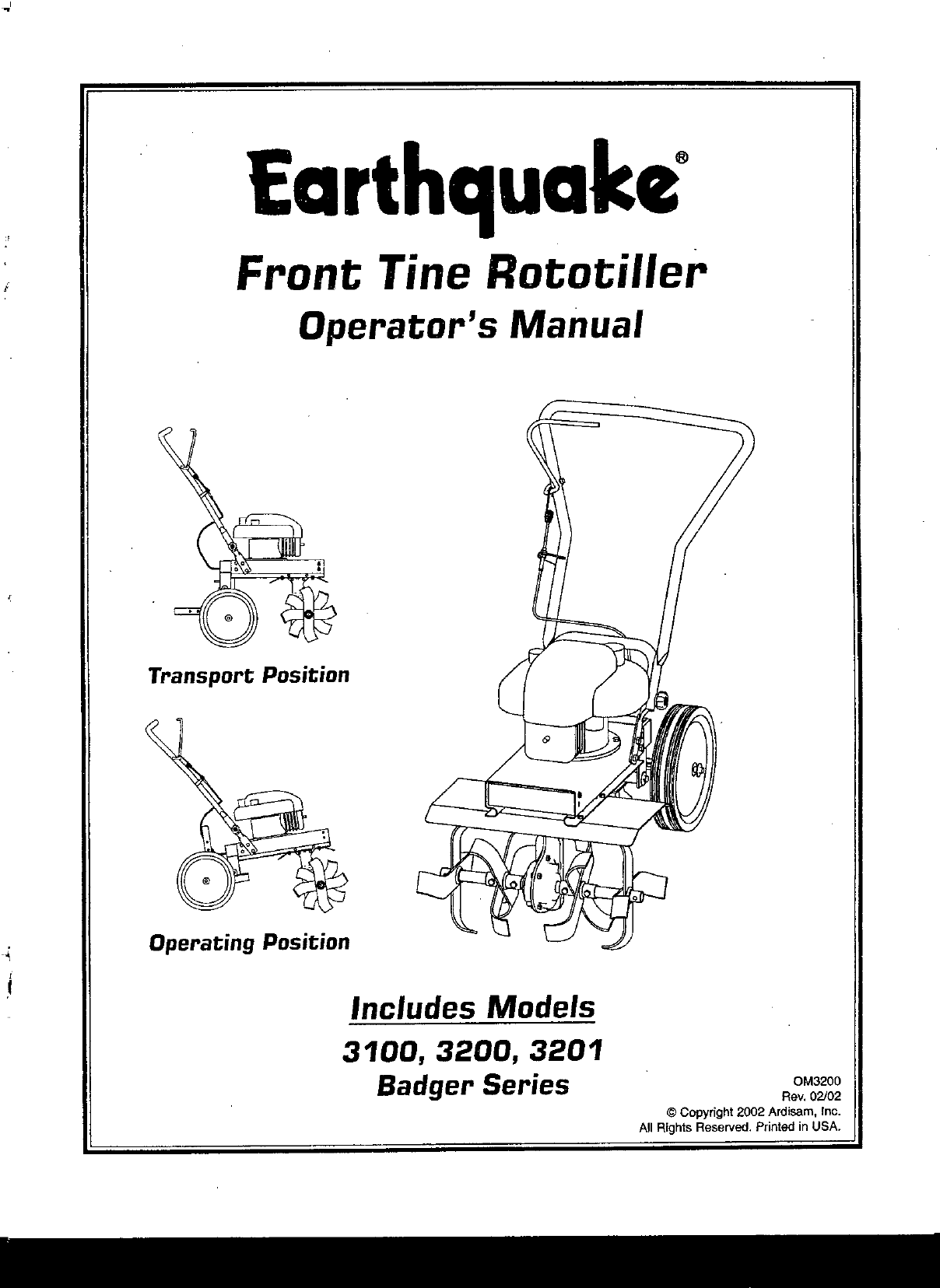

Provides helpful information for proper assembly,

operation, or maintenance of your rototiller.

Engine is shipped from factory without oil.You must

add engine oil before starting engine.

SAFETY RULES

OWNER'S RESPONSIBILITY

Safe and effective use of the rototiller is the owner's

responsibility

Read and follow all safety instructions.

Maintain the tiller according to directions and schedule

included.

Ensure that anyone who uses the tiller is familiar with

all controls and safety precautions.

GENERAL

A

The Safety Alert symbol shown here is used to

alert you to important safety information that must

be read, fully understood, and followed at all times when

handling, transporting, operating, servicing, or storing

your rototiller unit.

Each safety alert symbol is followed by a "signal word"

that advised you of the relative intensity, or level, of the

hazard the safety alert instructions pertain to.

The following list of signal words is being provided to help

you understand the intensity levels associated with each

signal word used in this manual.

A

DANGER

The signal word "DANGER" is used when a serious

Injury or fatality will result if the safety instructions

that follow this signal word are not obeyed.

A

WARNING

The signal word "WARNING" is used when a serious

injury or fatality could result if the safety

instructions that follow this signal word are not

obeyed.

A

CAUTION

The signal word "CAUTION" is used when personal

injury, or property or equipment damage could

result if the safety instructions that follow this signal

word are not obeyed.

CAREFULLY READ THIS MANUAL AND FOLLOW

ALL INSTRUCTIONS.

Be familiar with all controls before operating the tiller.

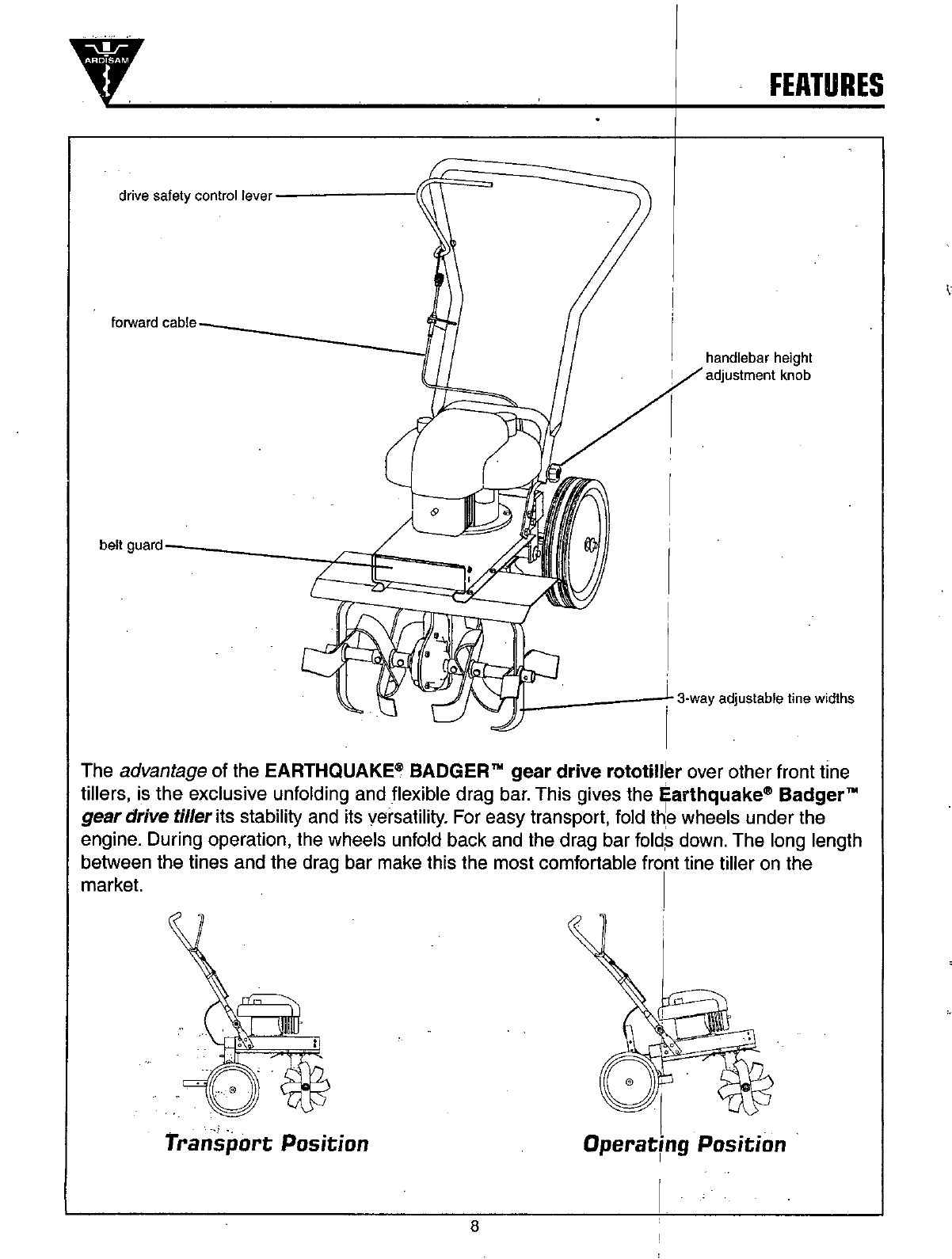

Your tiller is equipped with a safety device that enables

you to stop the tines quickly in an emergency. Learn

how the drive safety control lever works and how to

control the tiller at all times.

Never allow children to operate the tiller. Keep small

children away from the area being tilled. Do not allow

adults to operate the tiller without proper instruction

:

Do not operate the tiller under the influence of alchohol

or drugs.

PREPARATION

Dress appropriately when operating the tiller. Always

wear sturdy footwear. Never wear sandals, sneakers,

or open shoes, and never operate the tiller with bare

feet. Do not wear loose clothing that might get caught

in moving parts.

Carefully inspect the area to be tilled, and remove all

foreign objects. Do not till above underground water

lines, gas lines, electric cables, or pipes. Do not

operate the tiller in soil with large rocks and foreign

objects which can damage the equipment.

Disengage drive safety control lever before starting the

engine.

Handle fuel with care; it is highly flammable.

Use an approved fuel container.

Never add fuel to a running engine or hot engine.

Fill fuel tank outdoors with extreme care. Never fill

fuel tank indoors.

Replace gasoline cap securely and clean up spilled

fuel before restarting.

Never attempt to make any adjustments while the

engine is running.

5