I N S T A L L A TIO N TIP S

CARE + MAINTENANCE

Avoid acetone silicones upon installation, harsh chemicals and abrasive

cloths when cleaning (as these will scratch the chrome surface), waxed

based furniture creams (as these can result in a build up of deposits and may

detract from the appearance). Clean using a soft soapy cloth and polish with

a dry soft cloth and do not use undue pressure whilst cleaning. Ensure all

new installations are fully flushed prior to installing the ceramic headparts to

prevent any possible damage to the product and voiding of the warranty.

LICENCED PLUMBER/ INSTALLER

This water saving range of tapware and outlets have been fitted with flow

restrictors which can create greater hydrostatic back pressure to the ceramic

cartridge.

Always flush water inlet lines on new installations before fitting tapware to

avoid damage to ceramic valve.

Please Note:

- These tapware sets contain ceramic disc 180° turn spindles.

- Product not installed by a licensed plumber or in accordance with

relevant industry standards and regulations may void the manufacturers

warranty terms & conditions.

Please ensure the operating pressure to all points in the building conforms to

AS/NZS 3500.1 and does not exceed 500KPA .

Failure to limit the operating flow pressure, may void the warranty on this

fixture.

PRESSURE + TEMPERATURE REQUIREMENTS

Ensure operating water pressure is between 1-5 bar

(100-500Kpa).

If pressure is in excess of 500Kpa fit pressure reduction valve to ensure

installation conforms to AS/NZ 3500.1

This tapware set is not recommended for use with low pressure gravity feed

water systems.

Maximum hot water temperature 80°C.

WARRANTY

All Argent products are covered by a three (3) year warranty from the date

of purchase. Argent will undertake to rectify free of charge for parts and

labour, within this period any fault due to defects in materials or workmanship.

Regardless of interim service within that period, the warranty shall expire after

three (3) years from the date of original purchase.

Finishes

All Argent finishes are warranted against chipping and flaking, excluding

normal wear and tear for three (3) years from date of purchase.

Headpart s

All Argent replacement headparts will only be covered by warranty if the

fault can be clearly shown to have existed as a result of defect in manufac-

ture. There is a twelve (12) month warranty period only applicable for these

replacement parts.

Exclusions

This warranty is for normal domestic and commercial use only and excludes

any defect or injury caused by or resulting from misuse, abuse or neglect, ac-

cidental damage, improper installation or installation by unlicensed plumber,

products not installed to relevant National Standards and State Regulations.

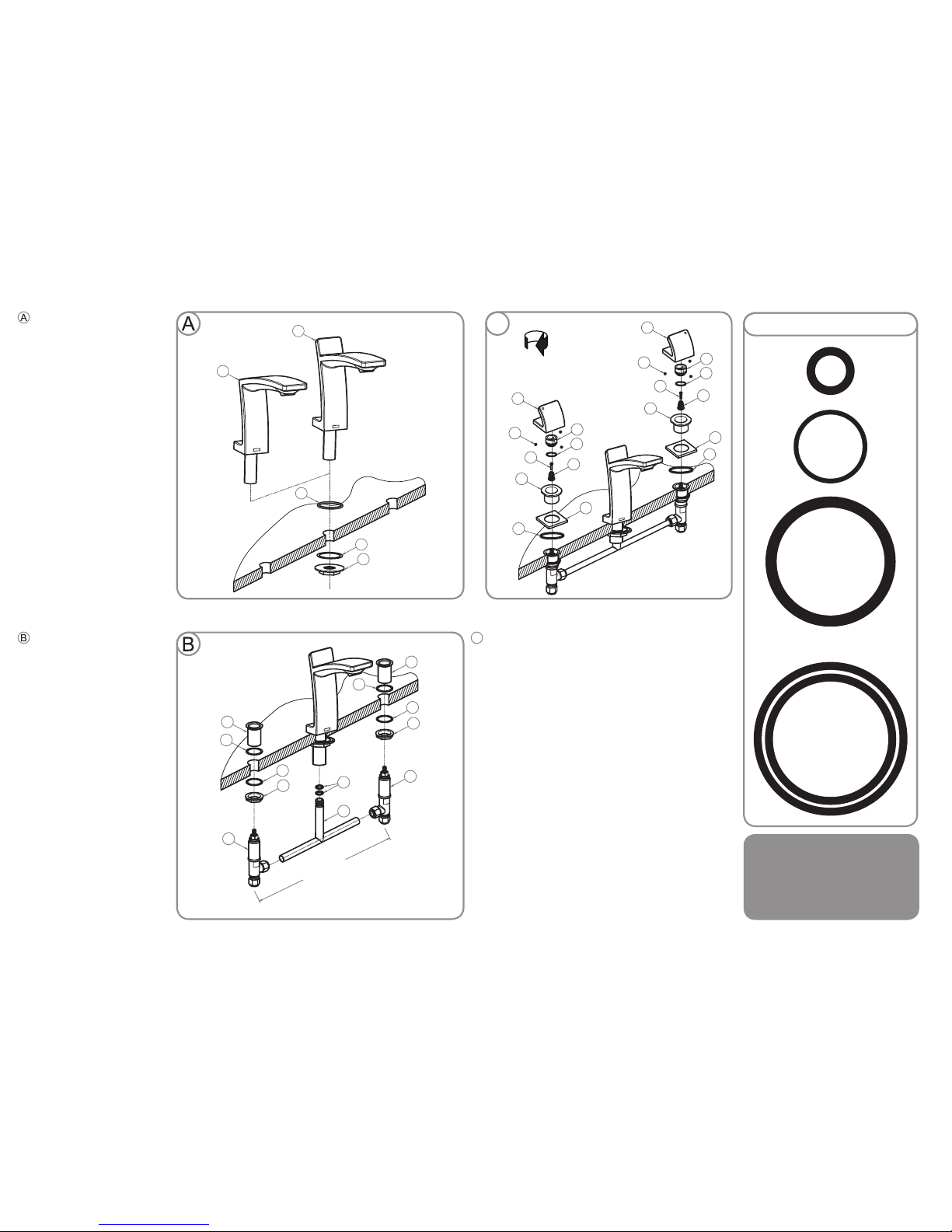

Z e n Basin S e t

I N S T A L L A TION INSTRUCTIO N S

WELS 5 star rated

Nominal flow rate 5Lpm

AS 3718

WMKA21008

SAI GLOBAL

107509

Zen S Basin Set

107409

Zen Basin Set

Brisbane

Level 3 / 18Wandoo Street

Fortitude Valley QLD 4006

Sydney

80 Abercrombie Street

Chippendale NSW 2008

Melbourne

198 Coventry Street

South Melbourne VIC 3205

Perth

Unit 1 / 40 Collingwood Street

Osborne Park WA 6017

Technical Advice

1800 356 717

Fax

1300 656 057

www.argentaust.com.au

The more

stars the more

water efficient

A joint government and industry program

Licence No. 0008

Whentested in accordance with Standard AS/NZS 6400

For more information and tocompa re

products,refer to:

www.waterrating.gov.au

5

Water Consumption

litres per minute

WATER

RATING

ARG-001-254, InsIns Zen BasinSet

Australian Design Registration

AUST. DES. REGN. NO. 307310

AUST. DES. REGN. NO. 307311

AUST. DES. REGN. NO. 307312