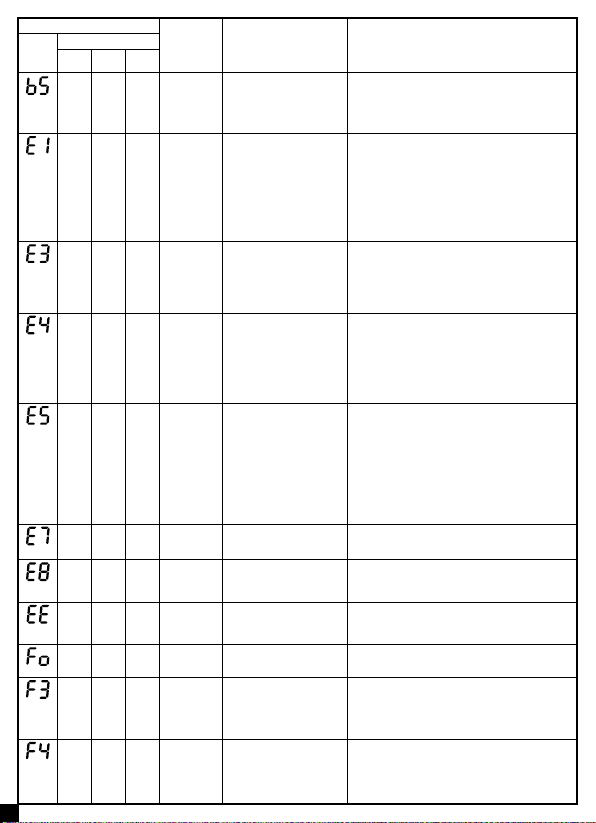

3

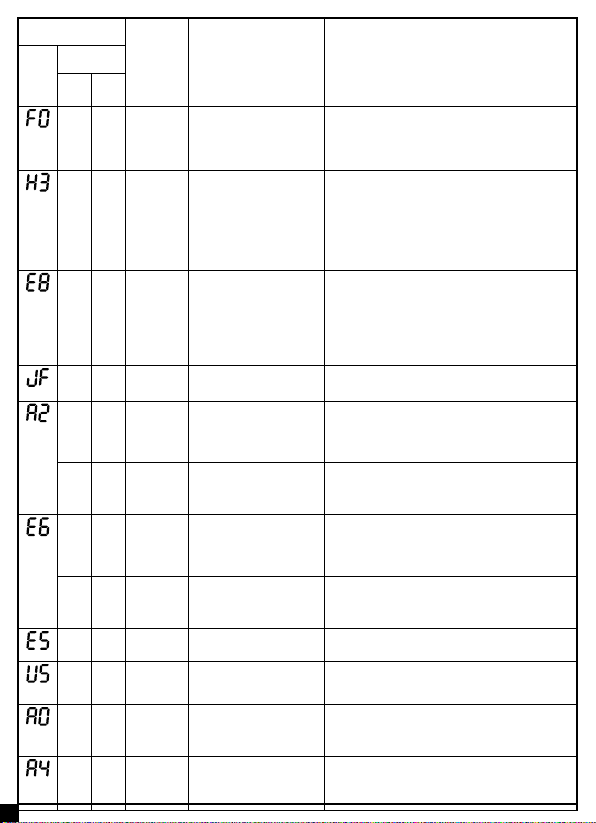

Display method of indoor unit

Malfunction

name AC status Possible causes

Error

code

Indicator display

Power

indicator

Cool

indicator

Heat

indicator

Flash 5

times

Outdoor air

discharge

temperature

is open/short-

circuited

Complete unit stops operation;

motor of sliding door is cut off

power.

1. The exhaust temperature sensor is not connected well or

damaged. (refer to Page 33 “Table 3”)

2.Temperature sensor wire of outdoor unit is damaged; short

circuit between the temperature sensor and copper pipe or

outer case

3.Main board of outdoor unit is damaged;

Malfunction of

micro switch

Cool/Dry: compressor stops

operation, while indoor fan

operates;

Heat: all loads stops operation.

1. The sliding door is blocked;

2. Malfunction of the photoelectric inspection panel of sliding

door;

Flash 4

times

System is

abnormal

Cool/Dry: all loads stops

operation except indoor fan;

Heat: all loads stops operation.

See Page 17 “High temperature prevention protection; high

power; system isabnormal”

Flash 7

times

Desynchronizing of

compressor

Cool/Dry: compressor stops

operation, while indoor fan

operates; Heat: all loads stops

operation.

See “Page 19 “Desynchronization diagnosis for compressor”

Flash 6

times

PFC protection Cool/Dry: compressor stops

operation, while indoor fan

operates; Heat: all loads stops

operation.

1. The power grid quality is bad; AC input voltage uctuates

sharply;

2. Power plug of air conditioner or wiring board or reactor is not

connected reliably;

3. Indoor and outdoor heat exchanger is too dirty, or air inlet/

outlet is blocked;

4. Main board of outdoor unit is damaged.

Flash

14

times

Demagnetization

protection of

compressor

Cool: compressor and outdoor fan

stop operation; Heat: compressor

and outdoor fan stop operation at

rst; about 1min later, indoor fan

stops operation.

1. The main board of outdoor unit is damaged;

2. Compressor is damaged;

Communication

malfunction

between indoor

unit and inspection

board

Normal operation 1. Poor connection between the indoor unit and the inspection

board.

2.The main board of indoor unit is damaged;

3. The inspection board is damaged;

Malfunction of

humidity sensor

Compressor, outdoor fan and

indoor fan stop operation;

The inspection board is damaged.

High power

protection

Cool: compressor and outdoor

fan stops operation, while indoor

fan operates.

See Page 17 “High temperature prevention protection; high

power; system isabnormal”

Flash

11

times

Start-up failed Cool/Dry: compressor stops,

while indoor fan operates; Heat:

all loads stops operation.

See Page 20 “Malfunction diagnosis for failure startup”

Lost phase Cool: compressor and outdoor fan

stop operation; Heat: compressor

and outdoor fan stop operation at

rst; about 1min later, indoor fan

stops operation.

1. The main board of outdoor unit is damaged;

2. The compressor is damaged;

3. The connection wire of compressor is not connected well.

Undened

outdoor unit

error

Cool: compressor and outdoor

fan stops operation, while indoor

fan operates; Heat: compressor,

outdoor fan and indoor fan stop

operation.

1. Outdoor ambient temperature exceeds the operation range

of unit (eg: less than-20oC or more than 60oC for cooling; more

than 30oC for heating);

2. Are wires of compressor not connected tightly?

3. Failure startup of compressor?

4. Is compressor damaged?

5. Is main board damaged?

Flash

15

times

Over-phase

current

protection of

compressor

Cool/Dry: compressor stops

operation, while indoor fan

operates; Heat: all loads stops

operation.

See “Page 13 “Overload protection of compressor , High

discharge temperature protection of compressor”

Flash

16

times

Communication

malfunction

between the

drive board and

the main board

Cool: compressor and outdoor

fan stops operation; Heat:

compressor and outdoor fan stop

at rst; about 1min later, indoor

fan stops operation;

1. The drive board is damaged;

2. The main board of outdoor unit is damaged;

3. The drive board and the main board is not connected well.

Flash

18

times

Circuit

malfunction

of module

temperature

sensor

Cool/Dry: compressor stops

operation, while indoor fan

operates; Heat: all loads stops

operation.

Replace outdoor control board