2

CONTENTS

1.Safety Precaution ……………………………………………………………............................................ 2

1.1 Installation ……………………………………………………………............................................... 2

1.2 Caution …………………………………………………………….............................................. 2

1.3 Operation ……………………………………………………………. ................................................ 2

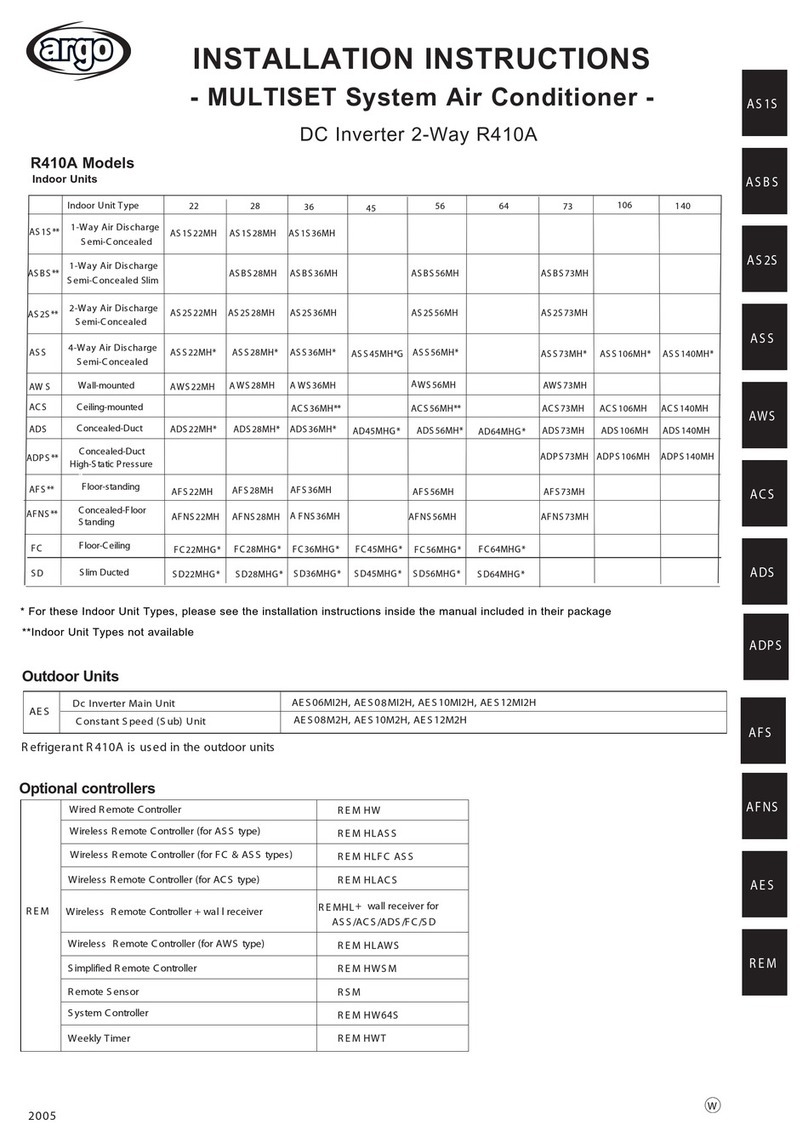

2.Specification ……………………………………………………………........................................... 4

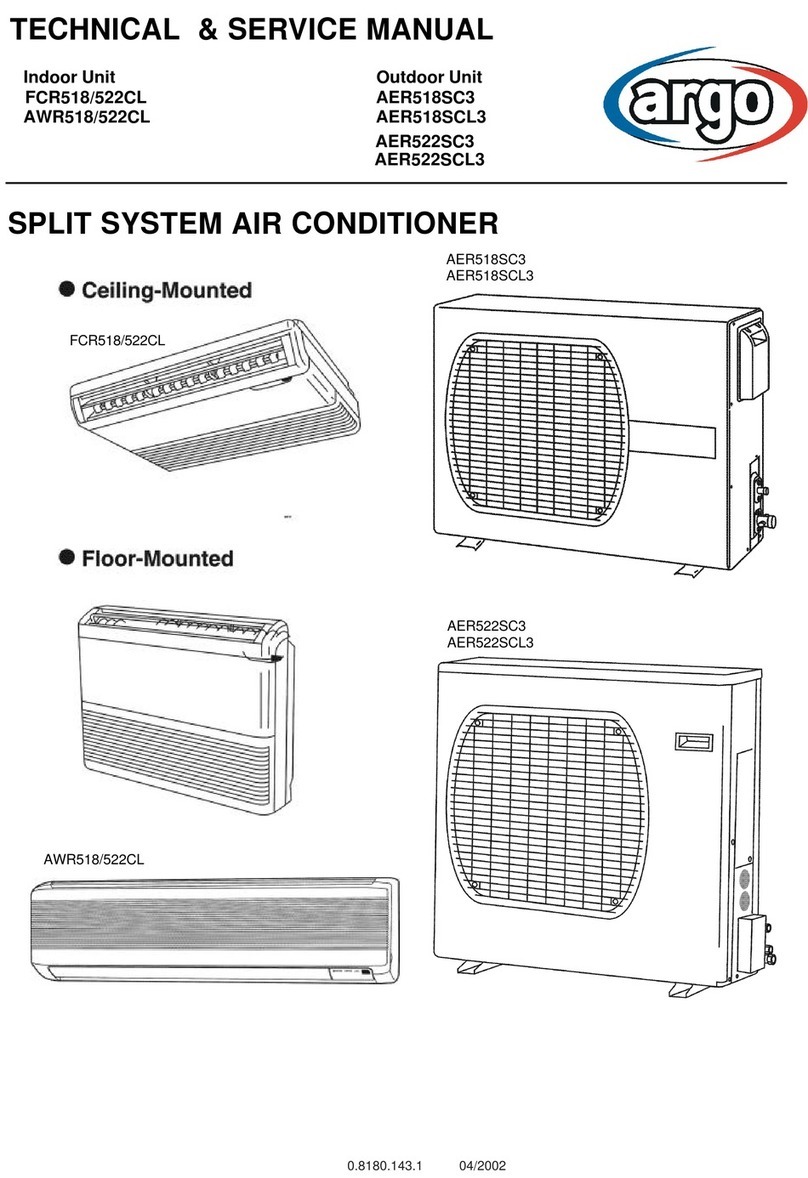

3.Outer Dimension …………………………………………………………… ........................................ 5

4. Refrigerant cycle diagram …………………………………………………............................................... 6

5.PCB drawing & wiring diagram ……………………………………………............................................. 7

6.Unit dissassembly sequence ………………………………………………………................................. 10

6.1 Casing Disassembly ………………………………………………………........................................... 10

6.2 Internal Parts Dissassembly ............................................................................................................. 13

7.Feature ............……………………………………………………………................................................. 16

7.1 Parts of the air conditioner ……………………………………………………… .................................. 16

7.2 Accessories …………………………………………………… .................................................... 17

8. Electronic Function …………………………………………………………… ........................................ 18

8.1 Function ……………………………………………………… ............................................................... 18

8.2 Controller Specifications ……………………………………………………… ...................................... 18

8.3 Controller Structure ……………………………………………………… .............................................. 18

8.4 Sensor Definitions ……………………………………………………… ................................................ 18

8.5 Mode ……………………………………………………… .................................................................... 18

8.6 Timer Setting ………………………………………………………........................................................ 20

8.7 Sleep ……………………………………………………… .................................................................... 20

8.8 Protection Function ……………………………………………………… .............................................. 20

9.Basic test procedure …………………………………………………………… ...................................... 23

9.1 Defective Compressor ……………………………………………………….......................................... 23

9.2 Sealed refrigeration repairs ……………………………………………………….................................. 24

9.3 Fan Motor ………………………………………………………............................................................. 26

9.4 Capacitor ………………………………………………………………… ............................................... 26

10.Characteristic of temperature sensor …………………………………… ............................................. 28

11. Trouble shooting …………………………………………………………… .......................................... 29

Appendix …………………………………………………………… ........................................................... 31

Trouble shooting problems …………………………………………………………… ................................ 31

Trouble shooting for electrical system ……………………………………................................................ 32