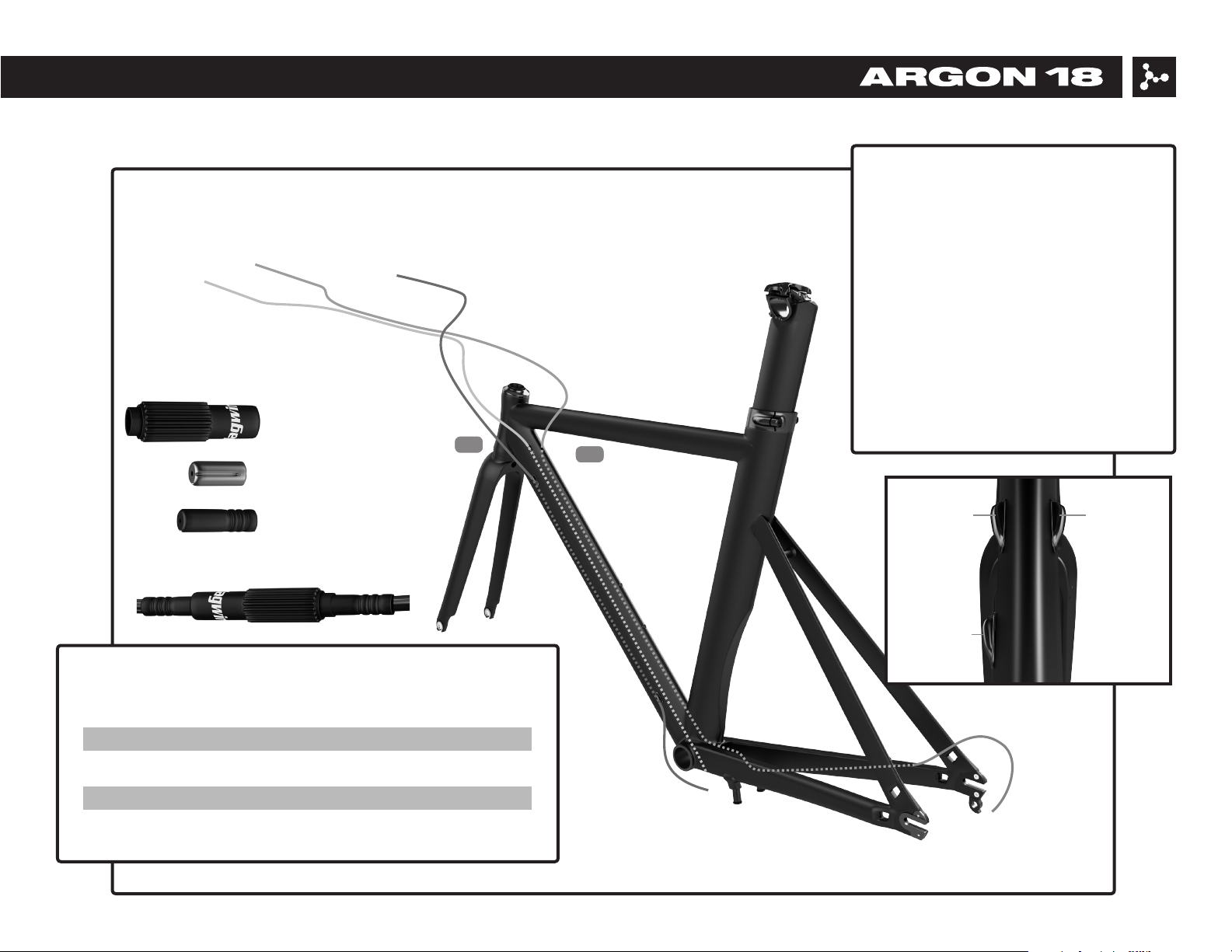

Assembly overview.........................................2

1. Frame inspection ........................................3

2. Cable housing installation..............................4-7

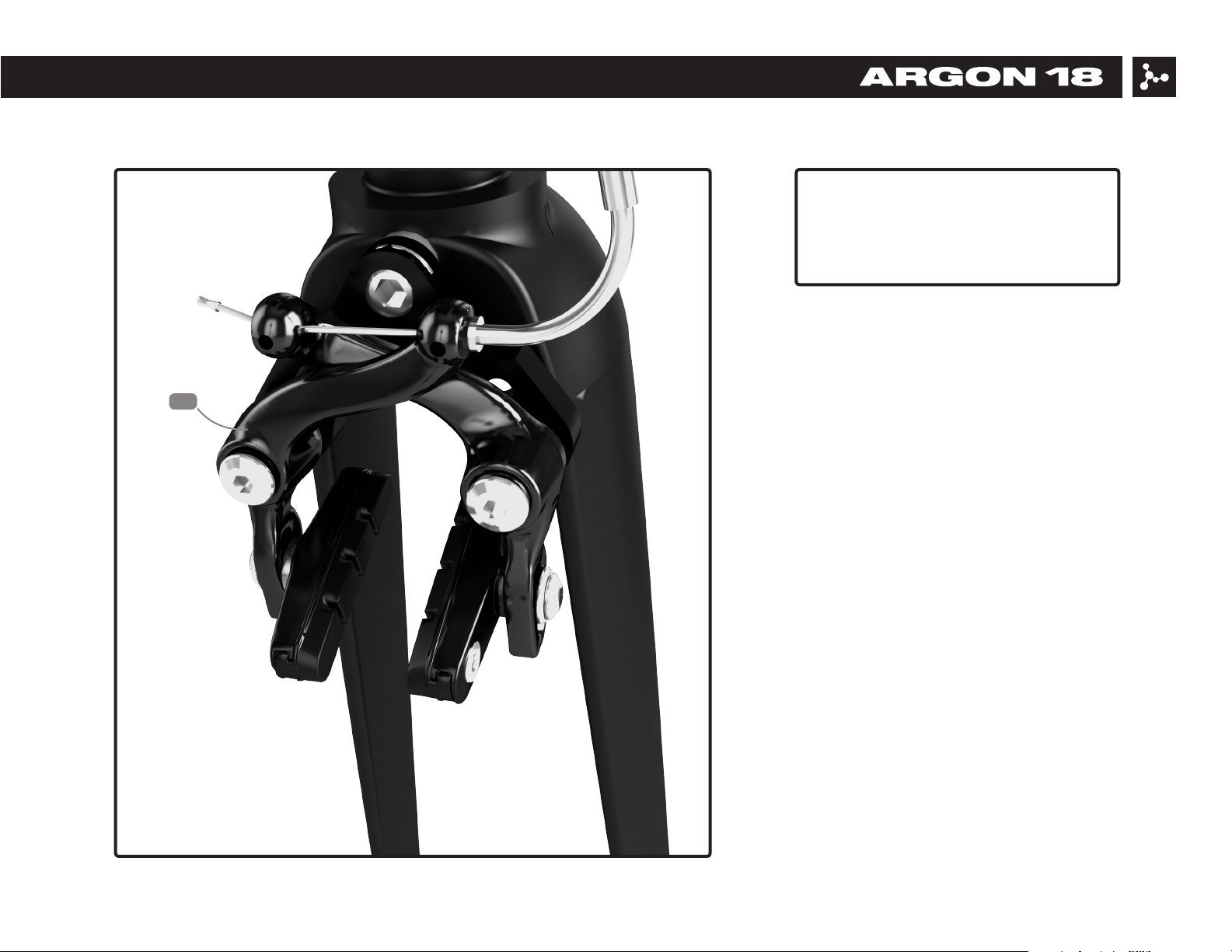

3. Brakes installation .....................................8-9

4. Seatpost installation ....................................10

5. Saddle adjustment .................................. 11-12

6. Parts’ SKUs and Descriptions ........................ 13-14

For the warranty to be valid, the bicycle must be fully assembled by an authorized Argon 18 dealer. High-end components,

particularly carbon parts, need extra care when assembled. Those components must be installed using a calibrated torque

wrench to make sure every bolt is at the right torque setting to prevent damage.

No more than 30mm of spacer can be place between the stem and the top cap of the 3D system.

And the use of more than 5mm spacer on top of the stem could void the eciency of the compressor.

These practices will automatically cancel any warranty claim against the manufacturer.

E-80 219A: Table of contents