P 1

01COR0909DDWW-V1

9x9 Corner Shed

2mm Drill bit

x2 Winter = High Moisture = Expansion

Summer = Low Moisture = Contraction

All building’s should be

erected by two adults

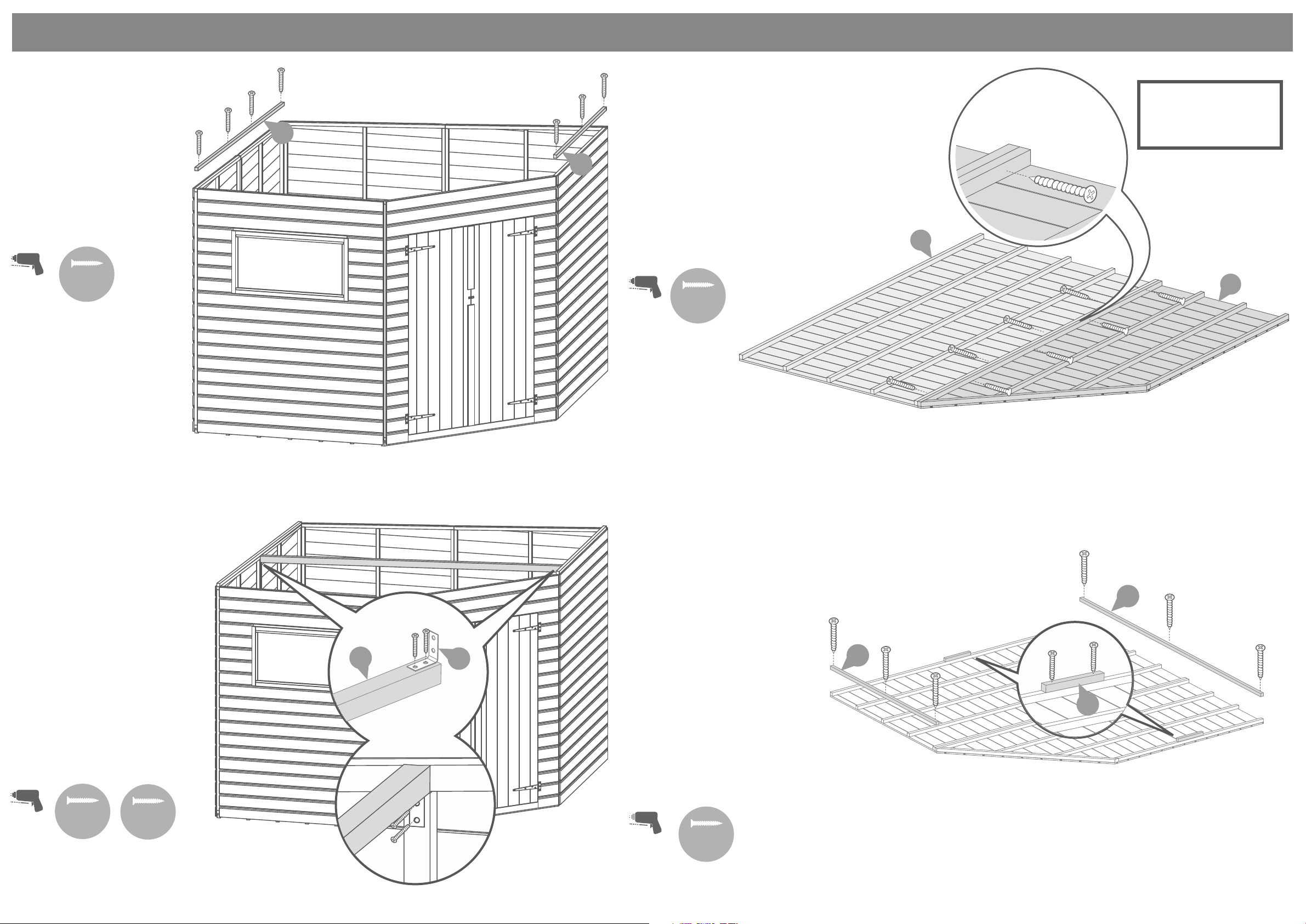

For ease of assembly, you

MUST pilot drill all screw

holes and ensure all screw

heads are countersunk.

For assistance please contact customer care on: 01636 880514

Mercia Garden Products Limited,

Sutton On Trent,

Newark,

Nottinghamshire,

NG23 6QN

www.merciagardenproducts.co.uk

CAUTION

Every eort has been made during the

manufacturing process to eliminate the

prospect of splinters on rough surfaces of the

timber. You are strongly advised to wear gloves

when working with or handling rough sawn

timber.

**Protim Aquatan T5 (621)**

Your building has been treated with Aquatan.

Aquatan is a water-based concentrate which is diluted with water, the building as been treated by the correct

application of Aquatan solution and then allowed to dry.

Aquatan is a decorative nish to colour the wood, which is applied industrially to timber fence panels and

garden buildings.

Aquatan undiluted contains: boric acid, sodium hydroxide 32% solution, aqueos mixture of sodium dioctyl

sulphosuccinat and alcohols: 2, 4, 6-trichlorophenol.

Please retain product label and instructions for future reference

General Instructions

BEFORE YOU START PLEASE READ INSTRUCTIONS CAREFULLY

- Check the pack and make sure you have all the parts listed.

- When you are ready to start, make sure you have the right tools at hand (not supplied)

including a Phillips screwdriver, Stanley knife, Wood saw, Step ladder, Hammer and a

Drill with 2mm bit.

- Ensure there is plenty of space and a clean dry area for assembly.

TIMBER

As with all natural materials, timber can be aected during various weather conditions.

For the duration of heavy or extended periods of rain, swelling of the wood panels may

occur. Warping of the wood may also occur during excessive dry spells due to an interior

moisture loss. Unfortunately, these processes cannot be avoided but can be helped. It is

suggested that the outdoor building is sprayed with water during extended periods of

warm sunshine and sheltered as much as possible during rain or snow.

Our buildings are pre treated with a water based treatment**; this only helps to protect

the product during transit and for upto 3 months against mould. To validate your

guarantee and ensure longevity of the product, it is ESSENTIAL the building is treated

with a wood preserver within the rst three months of assembly and thereafter in

accordance with the manufactures recommendations. Care must be taken to ensure

the product is placed on a suitable base.

BUILDING A BASE

When thinking about where the building and base is going to be constructed:

Ensure that there will be access to all sides for maintenance work and annual

treatment.

Ensure the base is level and is built on rm ground, to prevent distortion. Refer to

diagrams for the base dimensions, The base should be slightly smaller than the external

measurement of the building, i.e. The cladding should overlap the base, creating a run

o for water. It is also recommended that the oor be at least 25mm above the

surrounding ground level to avoid ooding.

TYPES OF BASE

- Concrete 75mm laid on top of 75mm hard-core.

- Slabs laid on 50mm of sharp sand.

Whilst all products manufactured are made to the highest standards of Safety and in

the case of childrens products independently tested to EN71 level, we cannot accept

responsibility for your safety whilst erecting or using this product.

Refer to the instructions pages for you specic product code

For ease of assembly, you

will need a tape measure to

check dimensions of

components.