Soil-Max Gold Digger Stealth ZD User manual

Drainage Plow Manual

Soil-Max, Inc.

Precise, Progressive, Great Service

888-Soilmax (764-5629)

Warning !!!!

Before using the Gold Digger drainage plow, call (888) 258-0808 (the toll-free

national call before you dig number). You need to have a determination made as

to whether or not any underground gas lines, electrical lines, fiber optic or normal

phone lines, or any other underground object or condition exist in the area you

will be running the plow. Have these thoroughly marked and maintain the

recommended distance from these areas.

Soil-Max is not liable for any damages or injury which may result from contact

with any above ground or underground object.

CALL (888) 258-0808

BEFORE YOU DIG!!

Page 2

Soil-Max Gold Digger Stealth ZD

“How-To” Guide

Thank you for purchasing the Soil-Max Gold Digger Stealth ZD. We know it is one of the most important

tools you will ever have on the farm. Our purpose is to develop equipment that will make farmers

profitable.

This “ How-to ” guide will explain the function and use of the Gold Digger. If you have any questions

about any Soil-Max equipment, or the use of this equipment for installation of field tile, please call our

office, toll free at (888) 764-5629 and we will be glad to discuss this with you.

Gold Digger Applications:

1. Add tile to already existing tile systems.

2. Random tiling systems, low draws, hillside seeps, etc.

3. New tile systems.

4. Installation of water lines, cables, etc.

5. Installing sub irrigation lines or tile for orchards, vineyards, high-cash crops and greenhouses.

Page 3

Table of Contents

Plow “Parts Identification”

5

Serial Number Identification

8

“Which Tractor” to Use

9

3pt Plow Hookup and Geometry

10

Toplink Cylinder

11

Draft Control/Quick Hitch

12

Hydrualic Hoses/Connections

12

Waterlevel

13

Pull-Type Plow Operation

13

Drawbar Placement

13

Down Pressure Manifold Electrical Schematics

15

Boot Removal

16

Shear Wear

16

Tile Feeder

17

Automatic Grade Control Hydraulic Schematics

17

Manual Grade Control Hydraulic Schematics

18

Electronics Hookup

19

TopCon Laser System Initial Setup

21

Apache Laser System Initial Setup

24

First Time “Using the Gold Digger in the Field

29

Incorporating s Second Pull Tractor

29

Pre Ripping

29

Manual Grade Control

30

Automatic Grade Control

30

Designing Tile Systems

31

Tile Size in Acres Drained Reference Chart

32

Using a Laser-Determining Grade & Coverage

33

Formulas for “Tile Grade Situations”

35

Frequently Asked Questions

36

Index

37

Page 4

Pull Type Parts Identification

Page 5

Water Level

Tile Boot Rollers

Walking Tandems (Optional)

GPS Arm Mount

Heel

Pull Hook

Grease Daily

Depth Chain

Proportional Valve

Downpressure Valve

Shear

Power Feeder Mount

3 Point Parts Identification

Page 6

Depth Chain

Water Level

7” Cylinders

6” Top Link Cylinder

erer

Proportional Valve

Owner’s Manual Storage

Top Link Tower

3pt Stands

Shear

Heel

Boot Funnel

Power Feeder Mont

GPS Arm Mount

Mount

Funnel Rollers

Hydraulic Valve Parts Identification

Down-Pressure Manifold Proportional Control Valve

(Controls Plow Wheels) (Controls Plow Shank Pitch)

See Index for Valve Schematic Diagrams

Page 7

Serial Number Identification

The serial number will contain the plow number, date of

manufacture and model information.

You want to use the serial number for insurance purposes.

My Serial Number: _______________________________________________________

Page 8

Serial Number

Plow Number

Tractor Selection

The first decision to make before attaching the plow to a tractor is “which tractor do I use?” It is not

necessarily true that the largest horsepower-rated tractor you have will work the best. You must take

into consideration the weight of the tractor, how good the tires are, what type of tire (radial or bias) and

the height of the tires. Keep in mind that a lower horsepower-rated tractor properly weighted may be

able to do the job to your satisfaction. Generally, a tractor weighing at least 20,000 lbs. can pull the

plow 3 to 3 ½ feet deep in good soil conditions.

If you are using the plow in good, dry soil conditions, it may be best to pull the plow without duals on the

tractor. This will allow all of the weight of the tractor to be transferred to a smaller surface area.

However, in less than ideal conditions, where the surface of the ground is slick or sticky, duals may

enhance traction. We do not recommend pulling the plow in very muddy conditions as this will probably

make your tiling job very frustrating and may cause compaction problems.

The charts below will give you an idea of what tractor to choose based on the depth you want to pull.

The depths are based on a 4 in boot. Every boot size increase such as 4 in to 6 in will reduce these

numbers by 20% roughly.

Page 9

Typical Tile Plow Depths

4in Boot (Normal Conditions)

Tractor Weight

(Lbs.)

Plow Depth 1

Pass

Plow Depth 2

Pass

20,000 –30,000

3.5 to 4 ft

4 to 4.5 feet

30,000 –40,000

4.0 to 5 feet

5 to 6 feet

40,000 +

5.0 to 6 feet

6.0 to 7 feet

Depth Factors

Rating

Comments

Radial Tires

Increase 5%

Tall 42" or 46" Tires

Increase 10%

Tall Helps

Tire Pressure

Increase 5%

Keep Under 15

lbs

Tire Lug Type

Increase 5%

We like big Lugs!

3-Point ZD Plow Hookup and Geometry

The 3-point comes equipped for Category III attachment. Attachment to a Category IV 3-Point hitch

is possible with the use of CAT III to CAT IV bushings. All pins and hardware should come with the

plow.

Adjusting the top link is very important. Attach your top link to the bottom or lowest hole on your

tractor and the highest hole you can reach on the plow. The ideal appearance of the 3 point arms

should look like the illustrations below. The 3pt arms should be evenly aligned with the plow frame.

The arms should not down into a “V” with the plow frame because this will place too much pressure on

the top link and it may break.

CORRECT

INCORRECT

Page 10

Please use the top hole on the plow for attaching the top link if possible. However, be careful when

lifting the plow the first time. On some tractors top link housing is directly beloow the stakc of

hydraulic couplings and may hit part of the tractor when the plow is raised. Spacer blocks are available

for John Deere 30 through 60 series tractors that may have this issue. The spacers extend the top

link out 3” farther from the tractor.

The top link must be adjusted so that the shoe of the plow does not drag the ground when the plow is

lifted. However, it is important that the bottom of the shoe is not any higher than 12 inches from

the ground when the plow is completely lifted.

You may also need to adjust the top link when you drop the plow into the first tiling run if the 3 point

arms do not allow it to go deep enough. You will want to make sure the two lower arms are locked so

that they do not float within the lift arm.

Toplink Cylinder

The Gold Digger ZD 3 point plow is equipped

with a hydraulic cylinder on the top link of the

three point hitch. The purpose of this cylinder

is to simply extend the geometry of the plow to

allow the maximum depth of the plow.

The correct position of this cylinder is to keep

the 3 point tower at a 90 degree angle to the

frame of the plow.

Draft Control Settings

The 3-point hitch will need its draft control turned completely off.

The 3-point hitch needs to float for the plow to work properly.

For most tractors this adjustment is made with only a knob or

lever. Refer to your tractor’s owner’s manual or dealer for

instructions. For some, however, there may be pins that will

need to be removed or changed for the draft to be turned off.

Some tractors with electronic controls require the 3 point hitch

to be cycled to complete the process after every start up of the

tractor. Check your owner’s manual for instructions.

Quick Hitch

WARNING!

DO NOT Use a Quick Hitch with the Gold Digger ZD 3-

Point Hitch Model Tile Plow. The geometry needed for

the plow to be lifted out of the ground and go down far

enough to reach the plow’s potential is not achievable

with a quick hitch Page 11

Hydraulic Hoses

The plow will come standard with pioneer hydraulic fittings. You will only need one set of hydraulic

outlets if a plow control system such as laser or GPS is used. A separate outlet will be needed for the

optional tile feeder. Make sure you connect to the tractor’s primary hydraulic remote. This

remote will need to have its hydraulic flow (speed) turned up all the way if possible.

Hydraulic fluid direction is important. In the front of each of the valve bodies is the letters “P” and “T”.

“P” is for Pressure and “T” is for Tank. Note: If the fluid is in the wrong direction, the valves will not

work correctly.

Hydraulic Connections

Tie up all hydraulic hoses and take care to remove any dirt from tractor remote connections and

pioneer fittings prior to connection with tractor remotes. Valve tolerances are very tight and

debris can cause malfunction of valves.

Page 12

Water Level

Once you have the plow attached, lower it on a flat surface. Lay a level alongside the shoe and read

the bubble. Now fill the water level with anti-freeze to the thick graduation where the red and green

graduated marks meet. This mark represents the shoe being level (0% slope). You will need to check

this again in one hour or so as the baffle in the water level may soak up some amount of anti-freeze.

NOTE: Water level is shipped upside down to guard against damage during transport. The level must

be turned upright for filling and use.

Shipping Position Operation Position with Fluid

Pull-Type Plow Operation

Drawbar Placement

When attaching a Gold Digger Stealth ZD Pull-Type plow to your tractor’s drawbar, please be sure that

the drawbar is pulled in as close to the tractor as possible to avoid breaking or damaging the drawbar.

This is especially important on smaller front wheel assist tractors.

Page 13

Hydraulic Detente

The wheels will not operate correctly if the tractor remote is detented (engaged) in the wrong

direction. The down-pressure valve has TANK and PUMP marked on the ports in the front of the valve.

The hose connected to the PUMP port should be stiff with pressure when detented (engaged) correctly.

Hydraulic Flow Only Goes One Way

Switchbox Instructions

The instructions in this section pertain to how you operate the wheels on a pull-type Gold Digger plow.

The wheels are operated by the black switchbox with either 2 or 3 switches. One switch is to move a

laser mast which would not pertain to you if you have an Intellislope or manual plow.

The switch marked “PLOW” operates the wheels. In the operation of tiling this switch is only used to

lower the plow into the start and pick the plow up after it has been steered to the top of the ground with

the 6” grade control cylinders. In other words, the plow must be brought to the surface of the ground by

pitching it UP with the 6” cylinders BEFORE it can be raised up off the ground with the wheels.

The “float” switch lowers the hydraulic pressure to the tires to around 200 psi. If you have more than

200 pounds of pressure, turn the round knob on the left side of the down-pressure block as shown in

the illustration counterclockwise to lower pressure. The float switch must be on to adjust the pressure. If

you need more pressure on the wheels turn the round knob clockwise. The plow must have enough

pressure to provide vertical stability for the plow, without so much pressure that the tires pull the plow

off grade when going over humps.

Normal Sequence of Operating the Wheels

1. With float mode off, lower plow into start with plow switch, Hold

plow on tires until movement begins.

2. As plow starts forward into soil, pull the shear into the soil about

2 feet, then turn on the float switch, pressure gauge should drop

to 200 psi.

3. Install tile with float switch on

4. When done installing, pitch the plow up with the large 7”

cylinders on top

5. Pull forward 8 to 10 feet.

6. Turn Float Switch off and raise the plow with the PLOW switch.

7. Warning!!! DO NOT use the plow switch to try to lift plow

when in the ground! Plow warranty is void when damage

occurs from plow being lifted out of ground by the wheels

and not by pitching the plow up and pulling the plow forward to the top of the ground

Page 14

Down Pressure Manifold

Electrical Schematics

Note: The position of the wires to the solenoids on the Down Pressure Manifold is very

important. With incorrect wire placement, malfunction of the manifold will occur and potential

injury. Please take care when removing, cleaning, or replacing wire connections.

Page 15

Boot Removal

Often during the course of an installation, different

boot sizes will be needed. Changing the boot is

easily done. First remove the fastener marked 1

and remove the funnel. Remove fastener marked

2 and the bottom portion of the boot will come off

in two pieces. Note the alignment pins on the

heel of the plow . Each size of boot has a

corresponding shear. Remove and replace with

the proper size shear.

Installation is the reverse of removal.

Shear Wear

Over time, the shear will wear on the cutting edge. How to gauge wear is shown in the illustration

below. Place a straight edge on the bottom of the cutting edge of the plow. The gap between the

shear and the heel will be about 3/8” when new. When the cutting edge of the shear is even with the

heel, the shear must be replaced.

Lack of replacement will cause the heel to wear excessively.

When the shear tip is even with the heel, the plow may try to come up and grade control will be

deteriorated.

Page 16

Tile Feeder (Optional)

The optional tile feeder is a great addition to any plow. It is not required but is a great reassurance of

tile quality. The tile feeder simply pushes on the tile to ensure no stretch is occurring.

Hydraulic fluid direction is important to correct operation. Take note of the direction the wheel turns;

the wheel should turn toward the plow. If reverse direction, change the direction of the fluid

detent. The hydraulic flow to the feeder should be slowed to reduce torque. When the plow

stops, the feeder should stop. The feeder is for assistance only not to rub and harm tile.

Start hydraulic flow very slowly ( 8 gpm or less ) and gradually increase. Flow too high will not allow tile

speed to be regulated with the rheostat switch.

If it’s not possible to adjust or slow the hydraulic flow, user should be ready to change the switch from

“on to “off” to stop the feeder. See the picture below of the control box. Turn the dial to adjust the

speed and move the switch for on/off of the feeder.

The tile feeder mounting brackets have three adjustments shown in the illustration below. Adjust the

feeder spring tension to give just enough tension on the spring to keep the tile in the wheel without the

tire. The hinge points of the tile feeder should be adjusted to align tile with funnel for an easy entry into

the funnel. Once adjusted, tighten to restrict moement.

Page 17

Hinge Points

Funnel Alignment

Spring Tension

Automatic Grade Control Plow Hydraulic Schematics

“T” Stands for “TANK”. This is the port through which oil returns to the reservoir.

“P” Stands for “PRESSURE” or “PUMP”. This is the port thorough which pressurized oil is sent to the

plow.

Page 18

Manual Grade Control Plow Hydraulic Schematics

“T” Stands for “TANK”. This is the port through which oil returns to the reservoir.

“P” Stands for “PRESSURE” or “PUMP”. This is the port thorough which pressurized oil is sent to the

plow.

Page 19

Electronics Hookup

Intellislope GPS Control System:

If you purchased the Intellislope GPS plow control system please refer to that systems manual for this

section. To learn more about the Intellislope you can visit: www.intellislope.com or call us toll free at:

888-SOILMAX and select Sales (option one).

Laser Guided Control System: (Also see Schematics following this page)

If you have purchased an automatic laser system, the electro-hydraulic valve mounts on the plow’s

frame below the top link attachment. This valve is hooked to the electronic control box to be put in the

tractor cab. It controls the hydraulic cylinders on the plow for automatic (using a laser) or manual

control of the shoe depth incrementally. The control box can be mounted in the tractor and needs 12

volt power supplied to it. There are two main cables to connect.

1. Connect the laser receiver cable to the receiver first.

2. Then connect the other end of the receiver cable to the control box in the cab.

3. Now connect the other cable to the control box and to the electro-hydraulic valve on the plow.

4. You will also have to connect the 12 volt power to the appropriate cable.

If you make the connections in this order, you will avoid any errors. You can, however, get the “up and

down” functions for the plow’s cylinders reversed. “Up” should extend the cylinders and “Down” should

bring them back in. If this is reversed, you may need to switch the hydraulic hoses going to the tractor

remote (they may be backwards), or just detent the hydraulic remote the other way. The valve block is

labeled where the hoses go in. One side is labeled “P” for pressure and the other side is labeled “T” for

tank. Make sure the hose that is under pressure is going into the block where it is labeled “P”. The

black and white wires (for lowering the plow) on the top of the valve should go closest to the middle of

the plow.

The laser mast should be mounted on the 3 inch tubing on the right side of the plow. It should be

mounted directly above the front of the plow shear. There will be a switch box which will need 12 volt

power to run the mast up and down. When traveling across field, lower the laser receiver to the

bottom of the mast to avoid damage. Traveling at high speeds may damage laser masts and

electronic sensors, please use discretion.

Page 20

Table of contents

Popular Farm Equipment manuals by other brands

Slootsmid

Slootsmid SB Eco Series user manual

Amazone

Amazone Citan 12001-C operating manual

Rosensteiner

Rosensteiner Kipp Top II Basic Operating, and servicing instructions

Rain-Flo Irrigation

Rain-Flo Irrigation CHALLENGER 1800 operating manual

CrustBuster

CrustBuster 4740 owner's manual

KUHN

KUHN GMD33 N Assembly & operators manual

Land Pride

Land Pride NTS2607 Operator's manual

Wiesenfield

Wiesenfield WIBS-002 user manual

Celikel

Celikel CHARGER V Series Operator's instruction manual

Precision Manufacturing Inc.

Precision Manufacturing Inc. 662000 Operator's manual

AIRTUG

AIRTUG TT-M-EM-2 Assembly & operating instructions

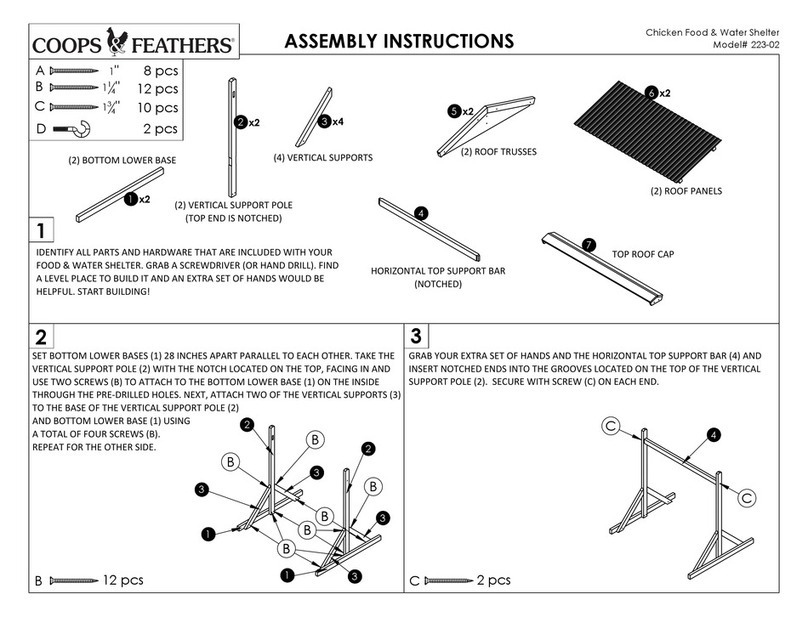

COOPS & FEATHERS

COOPS & FEATHERS 223-02 Assembly instructions