- BHC: If the burner head is clogged the amber LED “Burner head HOT / BHC“ will flash.

Additionally, if “burner head HOT / BHC“ is flashing, the maximum burning time in the operating

mode “Button“ and Pedal “StartStop“ is limited to 30 seconds (see paragraph 2.2). If burning

times longer than 30 seconds are required in case of a clogged burner head, the operating

mode “Standard“ can be used without time limit.

If “burner head HOT / BHC“ is flashing it is requested to clean the burner head immediately

(see paragraph 5.1).

- Automatic unit switch off: The unit switches itself off automatically after 4 hours if the flame

has not been lit in this period. All indicated malfunctions are automatically switched off after

4 hours, too. For further operation, switch the unit on again.

4. Error displays:

- Ignition failure: Green LED “Button“, “Standard“ or “StartStop“ blinks

2x

This signal appears and indicates a malfunction if the flame fails to ignite after 7 seconds.

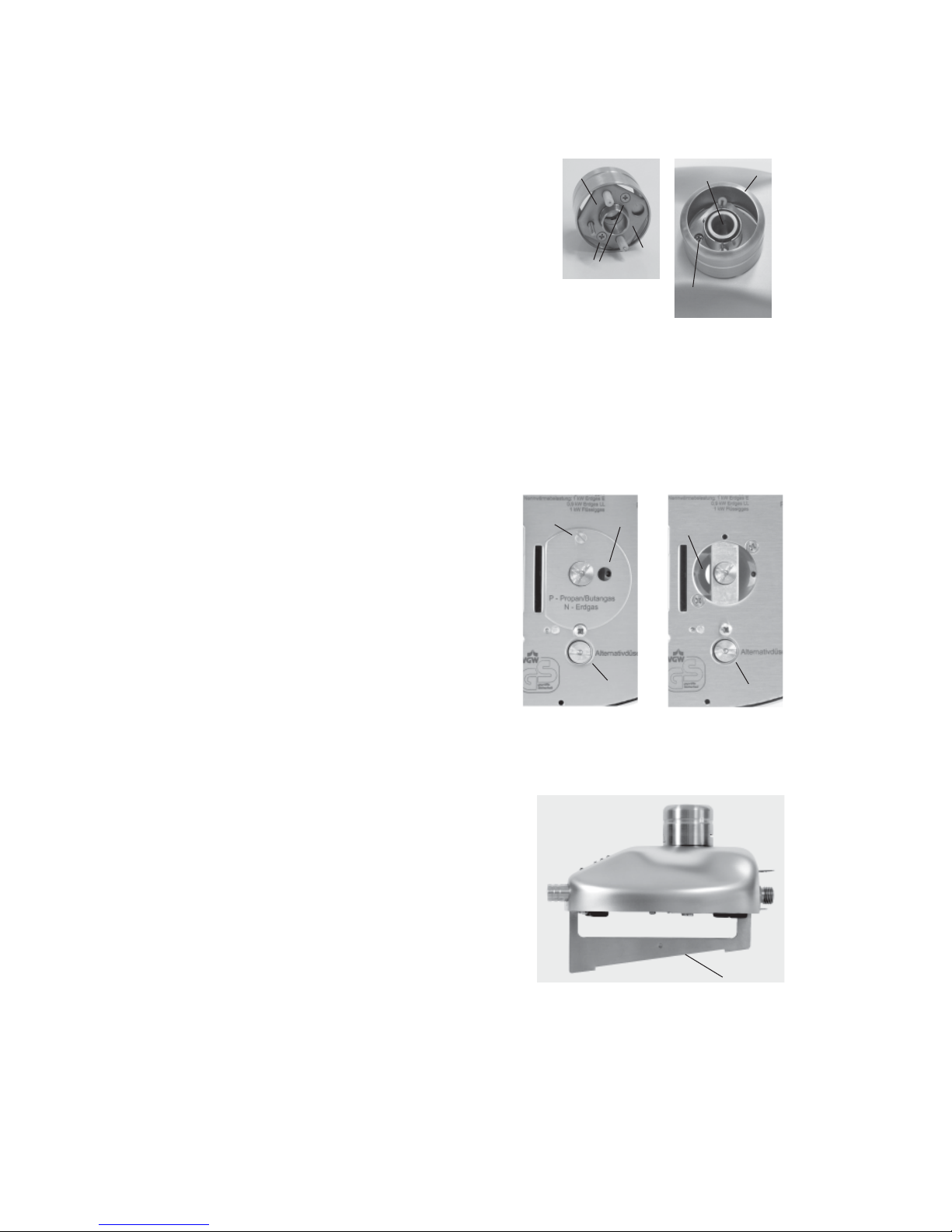

In case of ignition failure check the burner head (7) for possible clogging, check the correct

input pressure of the gas supply and verify that the correct nozzle is installed.

In case of this malfunction the gas supply will be shut off automatically.

Nozzle N (08): natural gas, 18-25 mbar Nozzle P (06): propane-/ butane gas, 47-57 mbar

- Flame failure: Green LED “Button“, “Standard“ or “StartStop“ blinks

3x

This signal indicates a malfunction if the flame is extinguished by external factors and fails

to reignite within 5 sec. In case of flame failure check the burner head (7) for possible clogging

and verify the correct input pressure of the gas supply.

In case of this malfunction the gas supply will be shut off automatically.

- Overtemperature: Green LED “Button“, “Standard“ or “StartStop“ blinks

4x

This signal indicates a malfunction if the interior temperature has exceeded 70 °C. At a normal

room temperature with normal air circulation the unit is suited for continuous operation.

In case of overtemperature increase the air ventilation or change the operation site.

In case of this malfunction the gas supply will be shut off automatically.

- Burner head assembly monitor:Green LED “Button“, “Standard“ or

“StartStop“ blinks

5x

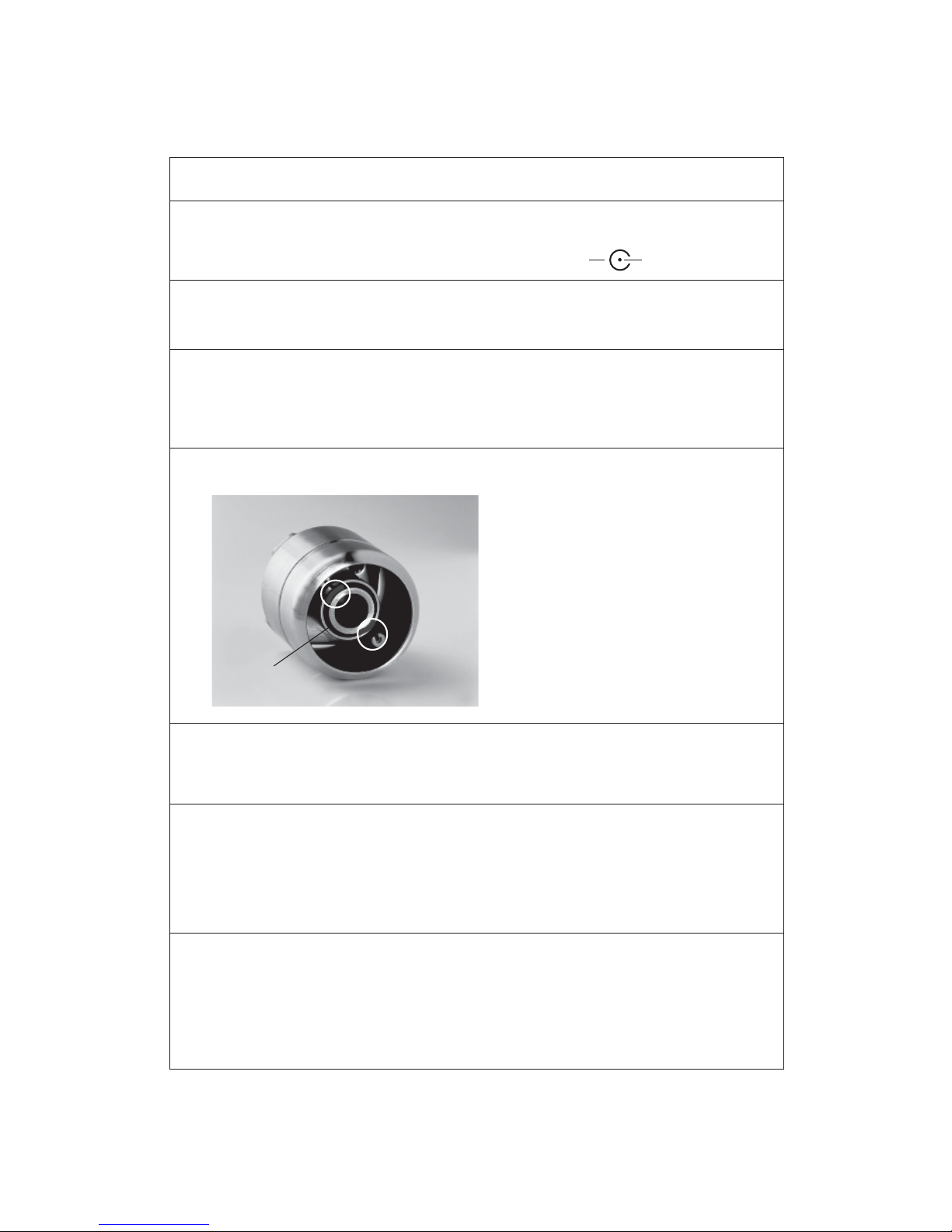

This message indicates that the burner head is removed. Further operation is possible after

the burner head is reinstalled.

- BHC: Amber LED “burner head HOT / BHC“ flashes

This signal indicates that the time limit (30 seconds) is turned on in operating mode “StartStop“

and “Button“ due to a clogged burner head. For cleaning the burner head see paragraph 5.1.

Notice: All error displays can be reset by a long push (2 seconds+) on the function knob (1).

(In case of overtemperature the unit needs to be cooled down and in case of burner head

assembly monitor the burner head needs to be reinstalled prior a reset is possible.)

5. Cleaning and sterilizing:

Allow sufficient time for burner orifice (7, 7a) to cool down before disassembling or cleaning

the burner head. Check the unit is disconnected and that the gas supply is turned off at the

mains. The burner can be cleaned with customary commercial disinfectants. Additionally, it

is possible to remove the burner head and to clean it separately.

The stainless steel and glass construction allow 100% UV-radiation sterilization and short

time surface flame sterilization.

Attention: Because of the connectors at the back of the unit the backside should not be

sterilized with a flame.

8