Aria QBVS110L User manual

OWNER’S MANUAL

MANUEL DE L’UTILISATEUR

MANUAL DEL USARIO

ULTRA QUIET HIGH AIRFLOW BATHROOM EXHAUST FAN WITH LIGHT

VENTILATEUR D’ÉVACUATION ULTRA SILENCIEUX ET HAUT DÉBIT AVEC

ÉCLAIRAGE DE SALLE DE BAIN

VENTILADOR DE EXTRACCIÓN ULTRASILENCIOSO Y ALTO FLUJO DE AIRE

CON LUZ PARA BAÑO

PLEASE READ AND SAVE THESE INSTRUCTIONS • INSTALLER: PLEASE LEAVE THIS GUIDE WITH THE HOME OWNER.

LISEZ ET CONSERVEZ CES INSTRUCTIONS • INSTALLATEUR: LAISSEZ CE GUIDE AU PROPRIÉTAIRE.

LEA Y GUARDE ESTAS INSTRUCCIONES • INSTALADOR: ENTREGUE ESTA GUÍA AL PROPIETARIO DE LA VIVIENDA.

QBVS110L

REV.20200113

QBVS110L 2

ENGLISH

Table of Contents

Safety Information ..................................2

Warranty

One Year Limited Warranty...........................3

Warranty Claim Procedure ...........................3

Pre-Installation

Tools/Materials Required ............................4

Package Contents .................................5

Typical Installation .................................6

Installation ........................................7

Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Care and Cleaning .................................13

Troubleshooting ...................................14

Specications

Wiring Diagram ..................................15

External Diagram of Fan Unit........................15

Service Parts......................................16

MANUEL DE L’UTILISATEUR ..........................17

MANUAL DEL USARIO ...............................32

Safety Information

WARNING:

WARNING – TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR

INJURY TO PERSONS, OBSERVE THE FOLLOWING:

1. Use this unit only in the manner intended by the manufacturer. If you have

questions, contact the manufacturer.

2. Before servicing or cleaning unit, switch power off at service panel

and lock the service disconnecting means to prevent power from being

switched on accidentally. When the service disconnecting means cannot

be locked, securely fasten a prominent warning device, such as a tag, to

the service panel.

3. Installation work and electrical wiring must be done by a qualied

person(s) in accordance with all applicable codes and standards, including

re-rated construction codes and standards.

4. Sufcient air is needed for proper combustion and exhausting of gases

through the ue (chimney) of fuel burning equipment to prevent back

drafting. Follow the heating equipment manufacturer’s guideline and

safety standards such as those published by the National Fire Protection

Association (NFPA), and the American Society for Heating, Refrigeration

and Air Conditioning Engineers (ASHRAE), and the local code authorities.

5. When cutting or drilling into wall or ceiling, do not damage electrical

wiring and other hidden utilities.

6. Ducted fans must always be vented to the outdoors.

7. If this unit is to be installed over a tub or shower, it must be marked as

appropriate for the application and be connected to a GFCI (Ground Fault

Circuit Interrupter) – protected branch circuit.

8. This unit must be grounded.

9. Always unplug or disconnect the appliance from the power supply before

servicing.

10. To reduce the risk of re or electric shock, do not use this fan with any

solid-state speed control device.

11. Do not install ventilation fan in a ceiling thermally insulated to a value

greater than R40.

12. Use an ON/OFF switch to operate this ventilation fan. Use of speed

controls may damage the motor.

13. If using a uorescent light bulb, do not use dimmer switch to control light.

14. DO NOT INSTALL IN A WALL.

WARNING: The unit has sharp edges. Always wear safety

gloves during installation, cleaning, or servicing.

CAUTION!

For general ventilating use only. Do not use to exhaust hazardous or

explosive materials and vapors.

DO NOT install this unit onto an acoustic ceiling panel.

This product is designed for installation in ceilings up to a 12/12 pitch (45

degree angle). Duct connector must point up.

To avoid motor bearing damage and noisy, unbalanced impellers, keep

drywall spray and construction dust away from power unit.

Please read specication label on product for further information and

requirements.

COOKING AREA

Do not install above or inside this area

Cooking

Equipment

45˚ 45˚

Floor

3 CONGLOMKB.COM

Please contact cs@conglomkb.com or 1-877-333-0098 for further assistance.

ENGLISH

Warranty

ONE YEAR LIMITED WARRANTY

A thorough inspection must be made before installation and any damage must be promptly reported. We will not be liable for failures or

damage that could have been discovered or avoided by proper inspection and testing prior to installation.

Conglom Inc. warrants this product to be free from defects in materials or workmanship for one (1) year from the date of purchase. Proof of

purchase (original sales receipt) from the original consumer purchaser must be made available to Conglom Inc. for all warranty claims.

This warranty is non-transferable and shall be voided if the unit is removed from its initial installation or if it is not installed following

the manufacturer’s instructions. It does not apply in the event of product damage due to the use of other than genuine Conglom Inc.

replacement parts, (Replacement parts may be obtained by e-mail at cs@conglomkb.com or by calling 1-877-333-0098 between

8:30 am - 5:00 pm EST) installation error, abuse, misuse or improper care and maintenance (whether performed by a plumber, contractor,

service provider or member of the purchaser’s household). The warranty excludes damage due to aggressive air or water conditions, harsh

or abrasive cleaners and/or materials.

Under no circumstance shall we be held liable for personal injury or property damage resulting from improper installation or use of this

product. We will not be held liable for inconvenience caused by loss of use of this product, costs incurred for labour or materials, removal

and installation of replacement units, or any other incidental or consequential damages. Costs relating to obtaining access for repair or

replacement are the responsibility of the user.

Our obligation shall be limited to the repair or replacement of a unit (at our discretion) that may prove, by our sole examination, to be defective

under normal use and service during the warranty period.

Any failure of this product that is not traceable to a defect in material or workmanship is not covered by this warranty. These non-warrantable

items include, but are not limited to:

-Improper installation not in accordance with manufacturer’s instructions.

-Dents and/or scratches incurred during shipping, handling, or installation.

- Change in colour or nish due to chemical usage.

-Damage caused by failure to follow care and cleaning guidelines, including damage caused by the use of abrasive cleaners.

-Alterations made to the unit by the purchaser or installer.

- Damage caused by accidental impact, re, ood, freezing, and normal wear.

- Bends and warping caused by forced connections, over-tightened ttings, and inadequate support during installation.

-Any defects or damage to light bulbs.

This warranty does not extend to commercial and institutional installation or use.

WARRANTY CLAIM PROCEDURE

If a claimable defect occurs or replacement parts are needed, please contact our customer service team at cs@conglomkb.com or

1-877-333-0098 (Service available in English and French, Monday - Friday from 8:30 am - 5 pm, EST).

Before you make your call, please ensure that you have:

-Model number or description.

-Proof of sale.

-Details regarding the defect and/or part number.

-Name(s) and address(es) of the owner and/or installer.

QBVS110L 4

ENGLISH

Pre-Installation

TOOLS/MATERIALS REQUIRED (NOT SUPPLIED)

Measuring tape Utility knife Pencil

Aluminum foil tape Phillips screwdriver Needle nose

pliers

Safety gloves Electric drill Safety goggles

Drywall saw Pry bar Wood screws

Respiratory mask Cable clamp Flexible duct

connector*

Duct adapter* Cloth Flathead

screwdriver

*For best performance use 4" round metal ducting. Other ducting is acceptable but may impact performance. Use of existing metal

ducting will require a short exible duct connector. If your ducting is other than 4” in diameter, a duct adapter is required to make an air

tight connection.

5 CONGLOMKB.COM

Please contact cs@conglomkb.com or 1-877-333-0098 for further assistance.

ENGLISH

Pre-Installation (continued)

PACKAGE CONTENTS

Carefully check this product for damage and/or missing parts prior to installation. If there is any damage or if you are missing parts, do not

proceed with the installation. Report damage and/or missing parts immediately to our customer service team at cs@conglomkb.com or

1-877-333-0098 (Service available in English and French, Monday - Friday from 8:30 am - 5:00 pm EST). Please do not dispose of packaging

until you are satised with your new product.

A CB

D

E F G H I

C

L

Part Description Quantity

A Ventilation Fan 1

B Damper 1

C Grille 1

D Light Cover (attached to grille) 1

E Light Bulb 1

F Installation Template and Dust Cover 1

G Hanger Channels 4

H Long Screws 4

I Short Screws 2

QBVS110L 6

ENGLISH

Pre-Installation (continued)

TYPICAL INSTALLATION

Roof Cap*

Wall Cap*

Elbows*

Aluminum

Foil Tape*

Power Cable*

Insulation*

Ventilation Fan

Round

or Flexible Duct

Connector*

* Not Included

or

Fig.1

7 CONGLOMKB.COM

Please contact cs@conglomkb.com or 1-877-333-0098 for further assistance.

ENGLISH

Installation

REPLACING AN EXISTING FAN

WARNING: Before removing the existing ventilation fan, switch

power off at service panel and lock the service disconnecting

means to prevent power from being switched on accidentally.

When the service disconnecting means cannot be locked,

securely fasten a prominent warning device, such as a tag, to

the service panel.

WARNING: Always wear safety goggles and gloves during

installation to prevent personal injury.

Center line

Center line

Installation

template (D)

Joist

Joist

Joist

Joist

Fig. 2

Fig. 3

Fig. 5

NOTE:

For new installations, please see “Securing the Fan to The Ceiling Joists –

Unnished Ceilings” section.

-Ensure the existing fan opening is smaller than the supplied

installation template so it can be enlarged to t the new fan if

required. Check to ensure the joist arrow indicated on the template is

oriented correctly. It should be pointing towards the ceiling joist.

- Mark the center line of the existing fan opening as shown in gure 2.

-Align the provided installation template with the joist side and center

line, then draw along the template perimeter. See gure 3.

-Using a utility knife, score the ceiling along the perimeter.

NOTE:

It is recommended that you wear a respiratory mask when cutting the

drywall and removing the old fan.

-Check to make sure the power to your existing fan has been switched

off at the service panel.

-Cut the new opening in the ceiling using a drywall saw. Be careful not

to damage the existing venting or electrical wiring. See gure 4.

-Disconnect existing ductwork and electrical wiring.

-Remove the old fan along with any installation hardware. Use a pry

bar if necessary. Once your old fan has been removed, you are ready

to install your new ventilation fan. See gure 5.

Fig. 4

QBVS110L 8

ENGLISH

Installation (continued)

PREPARING THE NEW FAN

WARNING: It is recommended that you wear safety gloves

when handling the ventilation fan because it has sharp edges

that could cause injury.

- Unplug the motor from the receptacle. See gure 6.

-Remove the screw securing the motor mounting assembly to

the fan housing and take the assembly out by releasing tabs.

See gure 7.

-Unscrew the screw securing the electrical wiring junction

cover and slide the cover upwards to remove it. See gure 8.

CONNECTING THE ELECTRICAL WIRING

WIRING CONNECTION REQUIREMENTS

OBSERVE ALL GOVERNING CODES AND ORDINANCES

1. Electrical grounding is required for this ventilation fan. Check

with qualied electrician if you are not sure whether the

ventilation fan is properly grounded.

2. Failure to follow electrical requirements may result in a re.

3. A fuse in the neutral or grounding circuit could result in

electrical shock.

4. If the hot/cold water pipe is interrupted by plastic nonmetallic

gaskets or other materials, DO NOT use for grounding.

5. DO NOT GROUND TO A GAS PIPE.

6. Save installation instructions for electrical inspector’s use.

7. If codes permit and a separate ground wire is used, it is

recommended that a qualied electrician determine if the

ground path is adequate.

8. DO NOT use an extension cord or adapter plug with this

appliance.

9. The ventilation fan must be connected with copper wire only.

Electrical Wiring

Junction Cover

Motor

mounting

assembly

Motor mounting

assembly

Fig. 6

Fig. 7

Fig. 8

9 CONGLOMKB.COM

Please contact cs@conglomkb.com or 1-877-333-0098 for further assistance.

ENGLISH

Installation (continued)

10. The ventilation fan should be connected directly to the switch

through exible, armoured or nonmetallic sheathed copper cable.

Allow some slack in the cable so the appliance can be moved if

servicing is ever necessary.

11. A UL listed or CSA approved conduit connector must be provided

at each end of the power supply cable.

12. Wire size must conform to all local codes and ordinances. The

latest edition requirements of the National Electrical Code ANSI/

NFPA 70, or the latest edition CSA Standards C22.1-94, Canadian

Electrical Code Part 1 and C22.2 No. 0-M91.

WARNING – TO REDUCE THE RISK OF FIRE, ELECTRIC

SHOCK, OR INJURY TO PERSONS, OBSERVE THE

FOLLOWING: Installation work and electrical wiring must be

done by qualified person(s) in accordance with all applicable

codes and standards, including fire-rated construction.

DANGER: Risk of electrical shock. This ventilation fan must be

properly grounded.

DANGER: Turn off the power circuit breaker or the power switch

on the junction box before installing this unit. Touching circuitry

inside the ventilation fan while it is energized will result in

death or serious injury.

DANGER: All electrical wiring must be properly installed,

insulated, and grounded. Improper insulation and grounding

will result in deadly electrical shock.

IMPORTANT:

It is the customer’s responsibility to contact a qualified electrical

installer and ensure that the electrical installation is adequate and complies with

the National Electrical Code, or CSA standards, as well as all local codes and

ordinances.

-Install a cable clamp (not supplied) to the wiring hole of the

fan housing in either of the two available locations as shown in

gure 9.

-Feed the electrical supply cable through the cable clamp. See

gure 9.

-Use UL approved connectors to connect the fan wires to your

electrical supply cable as shown in gure 10.

-Tighten the cable clamp to secure the electrical supply cable.

-Reinstall the electrical wiring junction cover to the fan housing

ensuring all wiring connections are fully enclosed. See gure 11.

Fan Housing

Switch Box

120 VAC Line In

Switch

(Not Supplied) = Black

= White

= Ground (Bare)

Cable

Clamp

= Blue

Motor

Receptacle

Light

Receptacle

Fan Housing

Switch Box

120 VAC Line In

Switch

(Not Supplied) = Black

= White

= Ground (Bare)

Cable

Clamp

= Blue

Motor

Receptacle

Light

Receptacle

Cable Clamp

Fan Housing

Switch Box

120 VAC Line In

Switch

(Not Supplied) = Black

= White

= Ground (Bare)

Cable

Clamp

= Blue

Motor

Receptacle

Light

Receptacle

One Single Pole Switch (Controls both fan and light together)

Two Single Pole Switches (Control fan and light independently)

Double Single Pole Switch (Control fan and light independently)

Fig. 10

Fig. 9

QBVS110L 10

ENGLISH

Installation (continued)

INSTALLING THE DAMPER TO THE FAN HOUSING

- If damper ap is not attached, t into place. Ensure the ap is

oriented correctly. See gure 12.

-Attach the damper to the fan housing and make sure all tabs

of housing are enclosed. See gure 13.

CONNECTING THE DUCT

NOTE:

Using flexible duct connector is recommended for the quietest possible

installation. If rigid duct is to be used, having a 1-3 feet section of flexible ducting

will allow for a quiet installation.

-Pull existing ducting through the ceiling opening. If

existing ducting is metal you will require a short exible

duct connector. Rigid duct may need to be cut for proper

installation.

-Position the fan housing assembly properly and secure

existing ducting to the fan's damper.

- If using a exible duct connector or duct adapter, use

aluminum foil tape at each end to secure the connector or

adapter to the existing ducting and to the fan's damper. See

gure 14.

-Ensure that the fan's damper is unobstructed and free to

swivel freely.

If you are replacing an existing fan then proceed to “Securing

the Fan to The Ceiling Joists – Finished Ceilings” section.

If this is a new installation and your ceiling is unnished,

proceed to “Securing the Fan to The Ceiling Joists –

Unnished Ceilings” section.

SECURING THE FAN TO THE CEILING JOIST -

FINISHED CEILINGS

DANGER: Turn off the power circuit breaker or the power switch

on the junction box before installing this unit. Touching circuitry

inside the ventilation fan while it is energized will result in

death or serious injury.

NOTE:

Ensure your fan is properly connected to the duct work and electrical

supply cable (not powered) before proceeding.

-With the motor mounting assembly removed, gently insert

the fan housing into the fan opening in the ceiling. Position

housing such that the bottom edges are aligned with the

ceiling surface.

-Secure the fan housing to the ceiling joist with screws.

Ensure the housing is fastened securely. Reinstall the motor

mounting assembly with tabs and screw. Plug motor into the

receptacle. See gure 15.

2

1

3

Screw

holes

Joist

Fan

housing

Motor mounting

assembly

Motor

receptacle

Ceiling

drywall

If your ducting is other than 4” in diameter,

a duct adapter is required (not supplied) to

make an air tight connection.

Existing house

ducting

Duct adapter

Aluminum

foil tape

Duct adapter

(optional)

Tab Fan

Housing

Electrical Wiring

Junction Cover

Fan Housing

Light

Receptacle

Motor

Receptacle

Fig. 12 Fig. 13

Fig. 14

Fig. 15

Fig. 11

11 CONGLOMKB.COM

Please contact cs@conglomkb.com or 1-877-333-0098 for further assistance.

ENGLISH

Installation (continued)

SECURING THE FAN TO THE CEILING JOIST -

UNFINISHED CEILINGS

DANGER: Turn off the power circuit breaker or the power switch

on the junction box before installing this unit. Touching circuitry

inside the ventilation fan while it is energized will result in

death or serious injury.

NOTE:

Ensure your fan is properly connected to the duct work and electrical

supply cable (not powered) before proceeding.

-Secure the ventilation fan to the ceiling joist in a

desired location. This fan offers several convenient

ways to secure the housing to your ceiling joists

(both conventional and I-joist). Choose the method

most appropriate to your ceiling construction as

shown in gures 16 and 17.

Joist Proles

-Reinstall motor mounting assembly. Plug the motor into the

receptacle. See gure 18.

-Power the fan to make sure everything is in proper working

order.

- Once you are satised with your installation, protect the bath

fan motor from construction dust and debris with the supplied

dust cover (D) until construction is completed. See gure 19.

Do not install the dust cover in nished construction. Do not

operate the fan with the dust cover in place as it will damage

the motor.

NOTE:

Duct and electrical connections not shown for clarity.

H

H

H

H

I

I

H

H

H

H

Ceiling

opening Joist

Ceiling

opening Joist

C

L

Dust cover (D)

Hanger

channels

Fig. 17

Fig. 19

Fig. 16

Fig. 18

QBVS110L 12

ENGLISH

Installation (continued)

INSTALLING THE LIGHT BULB

CAUTION:

To reduce the risk of electric shock, disconnect the

electrical supply circuit to the fan before installing light kit.

WARNING:

If using uorescent light bulb, do not use dimmer

switch to control light.

-With a piece of cloth in between to avoid scratching the

cover, use a athead screwdriver to pry the light cover out of

the grille. See gure 20.

- Screw light bulb into place. See gure 21.

- Properly plug light into receptacle. See gure 22.

-Test to ensure light works and reinstall light cover to grille.

INSTALLING THE GRILLE

-Squeeze the springs on the grille together, and insert the

springs into the slots of the housing assembly. Firmly push

the grille up against the ceiling. See gure 23.

Light

receptacle

Motor

receptacle

Spring slot

Ceiling

Pry here

Fig. 20

Fig. 21

Fig. 22

Fig. 23

13 CONGLOMKB.COM

Please contact cs@conglomkb.com or 1-877-333-0098 for further assistance.

ENGLISH

Operation

TURNING ON/OFF THE UNIT

-This ventilation fan with light can be operated with an external

switch.

-To operate the ventilation fan and light at the same time, use a

single pole (on/off) switch.

- To operate fan and light separately, use two single-pole switches

or a double single-pole switch.

- If using a uorescent light bulb, do not use dimmer switch to

control light.

WARNING: To Reduce The Risk Of Fire Or Electric

Shock, Do Not Use This Fan With Any Solid-State

Speed Control Device.

Care and Cleaning

WARNING: Failure to maintain basic standards of care and cleaning of the ventilation fan increases the risk of fire, electric shock,

or injury to persons. Before servicing or cleaning unit, switch power off at service panel and lock the service disconnecting means

to prevent power from being switched on accidentally. When the service disconnecting means cannot be locked, securely fasten a

prominent warning device, such as a tag, to the service panel.

WARNING: Ensure light bulb is cool enough to touch before replacing it.

The ventilation fan should be cleaned regularly (internally and externally) to preserve its appearance and performance. Remove grille, light

cover and light bulb to clean interior of ventilation fan.

Do: Do Not:

-Use a dusting brush attachment to gently vacuum

the exterior and interior of the ventilation fan to

remove dust and debris.

-Do not let plaster dust or any other construction

residue enter the fan. During construction or

renovation, cover the fan.

-Combustible products used for cleaning such as

acetone, alcohol, ether, or benzol are highly explosive

and should never be used close to the fan.

QBVS110L 14

ENGLISH

Troubleshooting

DANGER: Turn off the power circuit breaker or the power switch on the junction box before performing maintenance. Touching circuitry inside

the ventilation fan while it is energized may result in serious injury or death.

WARNING: Failure to maintain basic standards of care and cleaning of the ventilation fan increases the risk of fire, electric shock, or injury to

persons. Before servicing or cleaning unit, switch power off at service panel and lock the service disconnecting means to prevent power from

being switched on accidentally. When the service disconnecting means cannot be locked, securely fasten a prominent warning device, such as

a tag, to the service panel.

Problem Solution

The fan does not operate. -Check that the power supply cable and all electrical wiring are properly

connected.

-Check that the fan blade is not obstructed.

-Check that the power is turned on at the junction box or circuit breaker.

The fan vibrates when the fan is operating. -Check that the fan has been secured properly. Tighten into position, if

necessary.

-Check that the motor is secured in place. If not, then tighten the motor in place.

-Check that the fan is not damaged. If so, replace the fan.

The fan seems weak. -Check that the duct size used is of appropriate size. The fan will not function

efciently with insufcient duct size.

-Check that the duct is not clogged with debris and the tight mesh on the wall

cap, if applicable, is not restricting air ow.

-Check that the damper unit is opening properly.

-Check that no birds or animals have nested in the duct.

The fan is not venting properly. -Reduce the length of duct work and the number of elbows if necessary. Ensure

that all joints are properly connected, sealed, and taped.

-Check that the duct does not open against the wind.

The fan is making excessive noise. -Check to make sure there is nothing blocking the fan blade.

-The fan motor is permanently lubricated and does not need to be oiled or

lubricated. If the motor bearings are making excessive or unusual noises they

should be replaced. The fan blade should also be replaced at that time.

-Check to make sure that the fan's damper can pivot freely and is not

obstructed.

-Check to make sure the damper in the wall or roof cap can pivot freely and is

not obstructed.

The light does not work. -Check that the light bulb has been properly installed.

-Check that the power is turned on at the junction box or circuit breaker.

-Check that the light bulb is not broken. Do this by installing a light bulb that you

know is working.

15 CONGLOMKB.COM

Please contact cs@conglomkb.com or 1-877-333-0098 for further assistance.

ENGLISH

Specications

Model QBVS110L

Air Delivery (CFM - Cubic Feet Per Minute) 110 ±10%

Lound Level (Sones) 0.9

Duct Size 4" (10.16 cm)

Motor Power (W) 30

Voltage / Frenquency 120 VAC / 60Hz

Light 10W MAX

Housing Dimensions 11 3/8" x 10 1/2" x 7 5/8" (28.9 cm x 26.7 cm x 19.4 cm)

Grille Dimensions 13" x 13 3/4" (33 cm x 34.9 cm)

Net Weight (Kg) 3.93

WIRING DIAGRAM

Blue

Black

White

Ground

White

Ground

Switch Unit

TO CONTROL FAN AND LIGHT TOGETHER

White

Black

LIGHT

FAN

Blue

Black

White

Ground

White

Ground

Switch Unit

TO CONTROL FAN AND LIGHT INDEPENDENTLY

White

Black

LIGHT

FAN

White

120 VAC

Line In 120 VAC

Line In

White

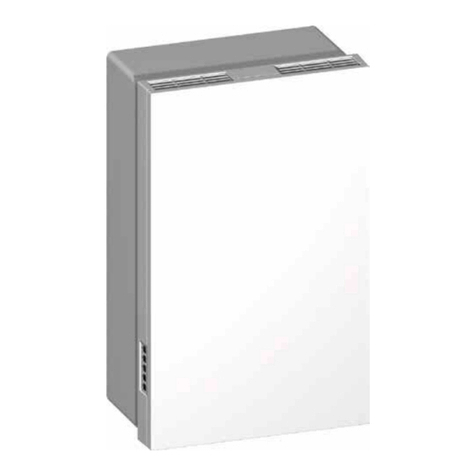

EXTERNAL DIAGRAM OF FAN UNIT

10 1/2"

(26.7 cm) 11 3/8"

(28.9 cm)

7 5/8"

(19.4 cm)

13 3/4"

(34.9 cm)

13"

(33 cm)

QBVS110L 16

ENGLISH

Service Parts

If you are missing parts or if you require replacement parts, please contact our customer service team at cs@conglomkb.com or

1-877-333-0098 (8:30 am – 5 pm, EST, Monday–Friday). Identify the required part(s) and have the part number(s) ready.

A B C

D E F

GH

Part Description Code Quantity

A Motor QHB183 1

B Fan Blade QHB191 1

C Damper QHB193 1

D Grille QHB180 1

E Motor Bracket QHB186 1

F Hanger Channel Set QHB195 1

G Light Cover QHB198 1

H Hardware Pack QHB197 1

Imported by / Importé par / Importado por :

St-Laurent, Québec, H4S 2C3

(service available in English and French, Monday - Friday from 8:30 am - 5 pm EST)

(service disponible en anglais et français, du lundi au vendredi, 8h30 à 17h, H.N.E.)

(servicio disponible en inglés y francés, de lunes a viernes, de 8:30 am a 5:00 pm, hora del Este )

www.conglomkb.com

Table of contents

Other Aria Fan manuals

Popular Fan manuals by other brands

Harbor Breeze

Harbor Breeze 40016 manual

Broan

Broan 512M instructions

Tecnosystemi

Tecnosystemi Apply.co IN LINEA 100 user manual

emerio

emerio FN-126821 instruction manual

Delta Electronics

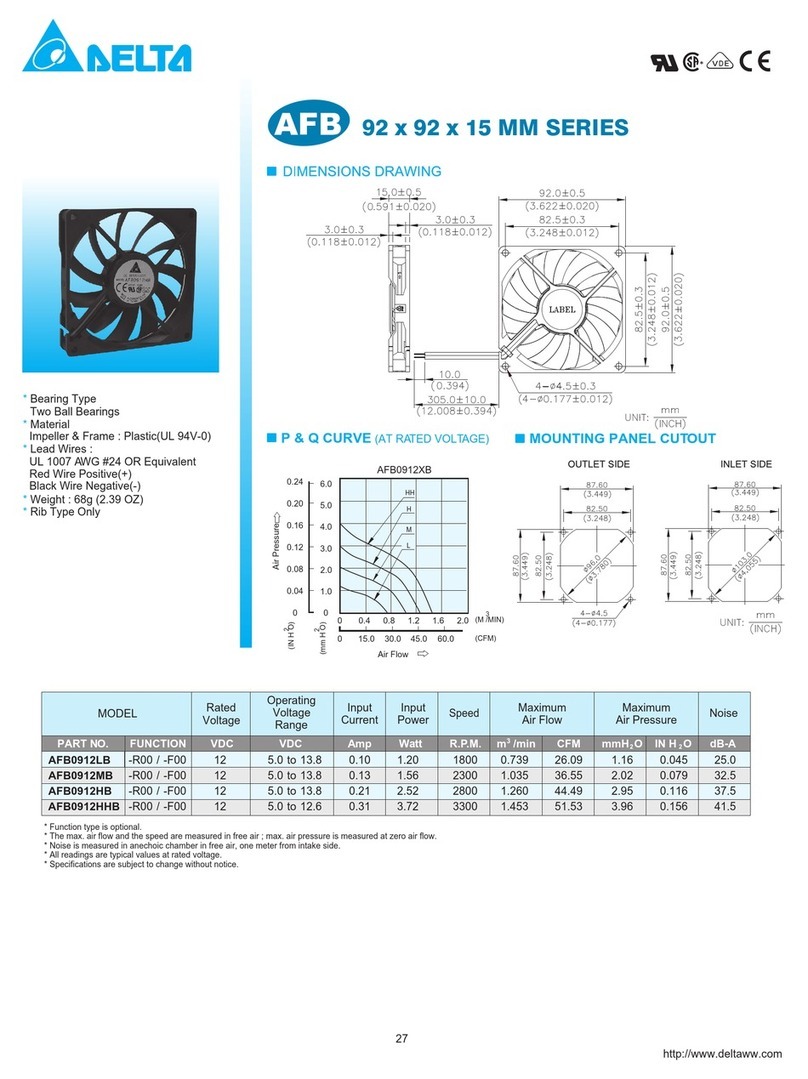

Delta Electronics 92 x 92 x 15 MM Series Specification sheet

GO FAN YOURSELF

GO FAN YOURSELF VividAir Z-Tech3 INSTALLATION & TECHNICAL OPERATIONS GUIDE