GB - 7

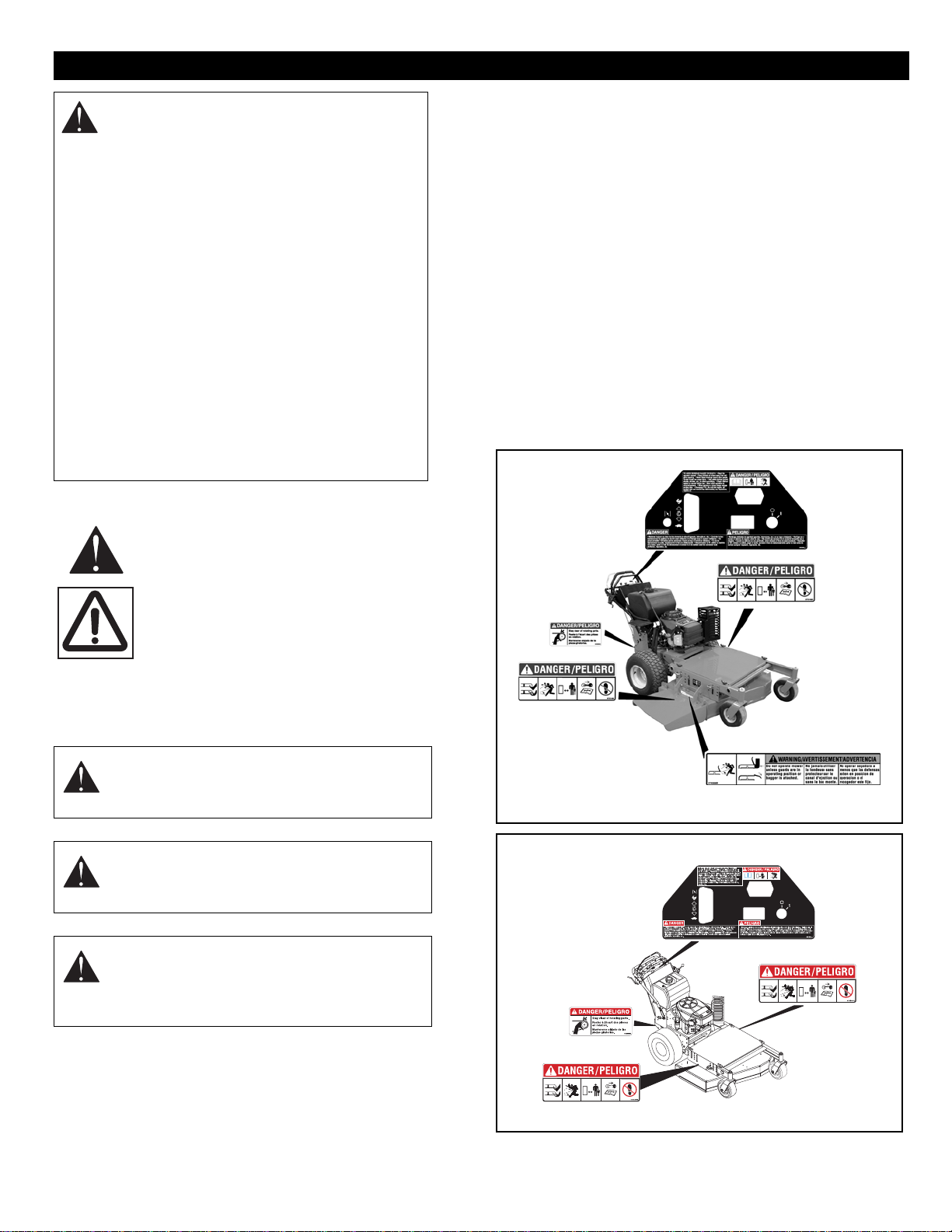

Read the entire Owner/Operator manual and other training

material. If the operator or the mechanic cannot read the

manual, it is the owner’s responsibility to explain it to them.

Only the user can prevent and is responsible for accidents or

injuries occurring to themselves, other people or property.

• Only trained adults may operate or service unit

• Training includes actual operation

NEVER allow children to operate or play on or near unit.

Be alert and shut off unit if children enter area.

Never carry passengers.

NEVER operate unit after or during the use of medication,

drugs or alcohol. Safe operation requires your complete and

unimpaired attention at all times.

NEVER allow anyone to operate this unit when their

alertness or coordination is impaired.

Wear adequate safety gear, protective gloves and footwear.

NEVER wear open sandals or canvas shoes during

operation.

Protect eyes, face and head from objects that may be

thrown from unit. Wear appropriate hearing protection.

Sharp edges can cut. Moving parts can cut off fingers or a

hand. Wrap blade(s), wear sturdy gloves and use extreme

caution when servicing. On multi-blade mowers, rotation of

one blade will cause all blades to rotate.

ALWAYS keep hands and feet away from all rotating parts

during operation. Rotating parts can cut off body parts.

ALWAYS keep hands away from all pinch points.

DO NOT touch unit parts which might be hot from operation.

Allow parts to cool before attempting to maintain, adjust or

service.

NEVER place your hands or any part of your body or

clothing inside or near any moving part while unit is running.

DO NOT wear loose clothing or jewelry. Tie back hair that

may get caught in rotating parts.

Keep children and people away from unit during operation.

Fumes from engine exhaust can cause injury or death.

DO NOT run engine in an enclosed area. Always provide

good ventilation.

Thrown objects can cause injury and property damage. DO

NOT point discharge at anyone or discharge directly onto

paved or gravel surfaces.

Always stand clear of the discharge area when operating

this unit.

Read, understand, and follow all instructions in the manual

and on the machine before starting. Understand:

• How to operate all controls

• The functions of all controls

• How to STOP in an Emergency

• Braking and steering characteristics

• Turning radius and clearance

ALWAYS keep protective structures, guards, and panels in

good repair, in place and securely fastened.

NEVER modify or remove safety devices.

ALWAYS keep discharge cover or complete grass catcher in

place and in proper working condition.

Check steering control operation frequently. Adjust and

service as required.

Safety Interlock System must function properly. DO NOT

operate unit if operator presence control is damaged or

disabled.

If you strike an object, or if equipment vibrates abnormally,

stop engine at once, disengage PTO, wait for all moving

parts to stop, and remove key. Check for any damage or

loose parts. Repair before restart.

Before starting engine: disengage PTO, engage parking

brake and place unit in neutral.

DO NOT operate at too fast a rate. DO NOT change engine

governor settings or over-speed engine. Slow down and turn

corners slowly.

Disengage PTO when attachment is not in use. DO NOT

raise deck with blades running. ALWAYS turn off power to

attachment when travelling, crossing driveways, etc.

Avoid uneven and rough terrain. DO NOT operate near

drop-offs, ditches, or embankments. Unit can suddenly turn

over if a wheel is over the edge of a cliff or ditch, or if an

edge caves in.

DO NOT try to stabilize unit by putting foot on ground when

operating with applicable riding attachments.

When engine is running and speed control lever is forward,

holding only one steering lever will cause unit to circle

around one drive wheel.

Use care when approaching blind corners, shrubs, trees or

other objects that may obscure view.

ALWAYS disengage PTO, stop unit and engine, set parking

brake, remove key and allow moving parts to stop before

clearing clogs or cleaning unit.

Never leave a running unit unattended. ALWAYS shut off

engine before leaving unit.

ALWAYS remove key to prevent unauthorized use.

DO NOT operate in reverse unless absolutely necessary.

ALWAYS backup slowly. ALWAYS look down and behind,

before and while backing.

DO NOT operate on steep slopes. DO NOT operate on

slopes of more than 10°. Operate across the face of slopes,

not up and down.

Turf conditions can affect the unit’s stability.

Keep all movement on slopes slow and gradual. DO NOT

make sudden changes in speed or direction. Use a slow

speed to avoid stopping or shifting on slopes. Avoid starting

or stopping on a slope.

DO NOT park unit on a slope unless absolutely necessary.

When parking on a slope always engage parking brake and

block wheels.

Use extra care when loading or unloading unit onto trailer or

truck.