03936900 6/09 Page 3 of 4

4. Route the red/white and black wires to the battery.

5. Attach the ring terminal on the black wire to the

negative (–) post of the battery.

6. Attach the ring terminal on the red/white wire to the

positive (+) post of the battery.

7. Route the red and brown leads of the wiring

harness (item 26) to the front of the unit and

connect to the lift motor plug. Attach the wiring

harness to the front of the unit with cable tie

(item 20).

IMPORTANT: Make sure that the front tie point of the

wiring harness to the unit allows full movement of the

plow without placing any tension on the harness.

8. Insert the relay (item 13) into the relay socket on

the wiring harness (item 26).

9. Using a 12-volt test light or meter, locate an existing

wire on the unit that is only energized when the key

switch is in the ON position.

10. Attach the yellow wire from the relay socket to the

wire just located with one Scotchlok connector

(item 22).

IMPORTANT: Connecting the yellow wire to a wire that is

not controlled by the key switch will discharge the battery.

11. Secure wiring harness to unit with remaining cable

ties.

12. Ensure that fuse is inserted in fuse holder and turn

the key switch to the ON position.

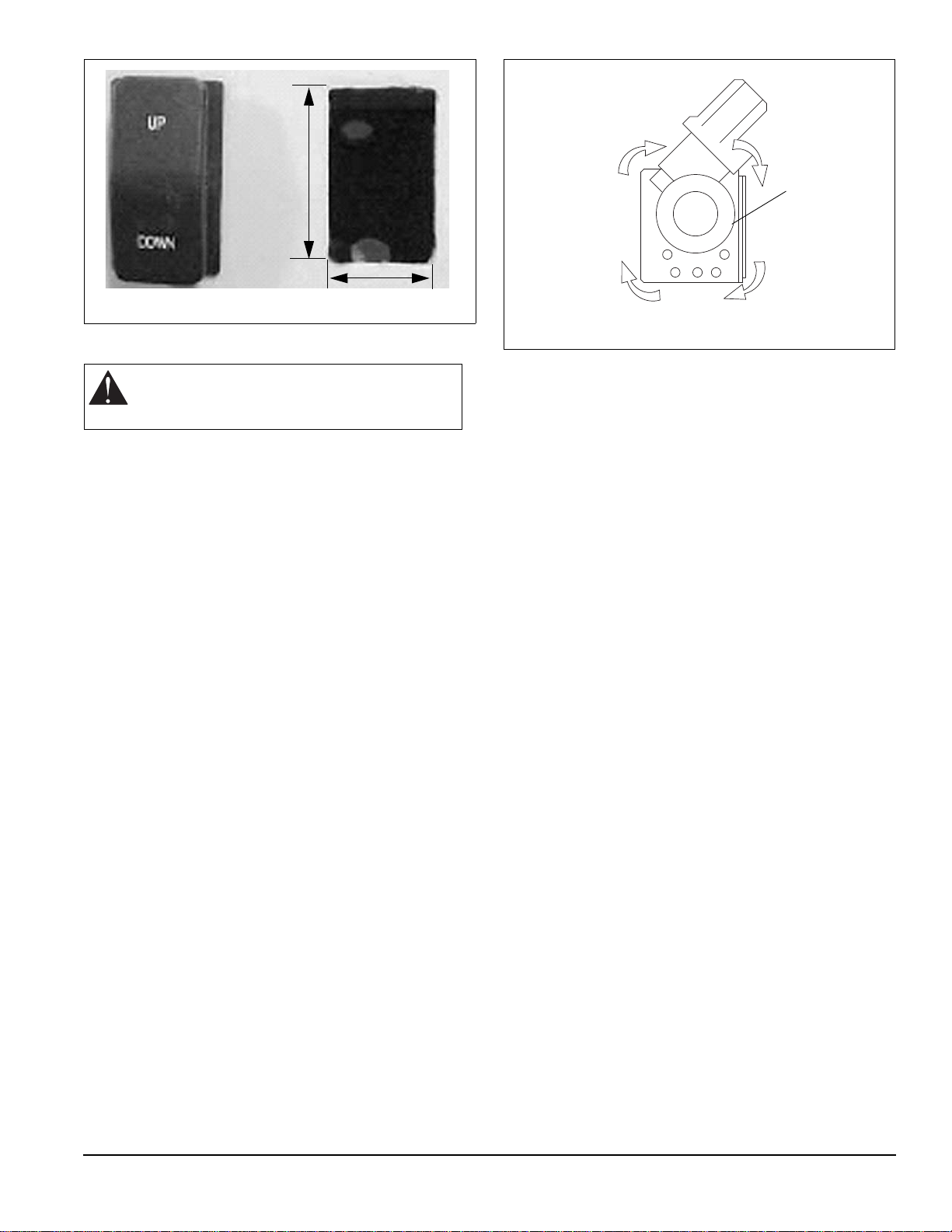

13. Press the motor switch to the UP position and verify

that the spool on the lift motor rotates clockwise

when viewed from the open end (figure 5). If the

spool rotates counter-clockwise refer to the wiring

diagram in figure 6.

14. Run the spool in the direction needed to result in

one wrap of cable on the spool and the cable to the

front of the spool.

15. With the blade resting on the ground, route the end

of the cable up through the quick link (item 8) and

the lift strap (item 6) and secure it with the cable

clamp (item 7).

Operation

Press the blade switch in the UP position to raise the

blade and in the DOWN position to lower the blade.

Important operating points:

• Release the switch as soon as the blade is up. If the

blade is raised too high the push tube will contact

the unit’s frame and overload the gear motor and

other parts. This may also lead to fuse failure.

• Release the switch as soon as the blade is down. If

the switch is held in the DOWN position after the

blade is on the ground, the cable will start to wind

backward on the spool.

Occasionally lubricate each end of the spool with oil.

CAUTION: Ensure that all wires are routed

away from moving parts, hot components or

areas where they may be damaged.