EN 7

N

37878

05-2017

2. Safety

2.2

Safety instructions applicable during operation, maintenance and repair

ãTerberg Machines .V., IJsselstein, The Netherlands

All rights reserved. No part of this book may be reproduced, stored in database or retrieval system, or published, in any form or in any way,

electronically, mechanically, by print, photoprint, microfilm or any other means without prior written permission from the publisher.

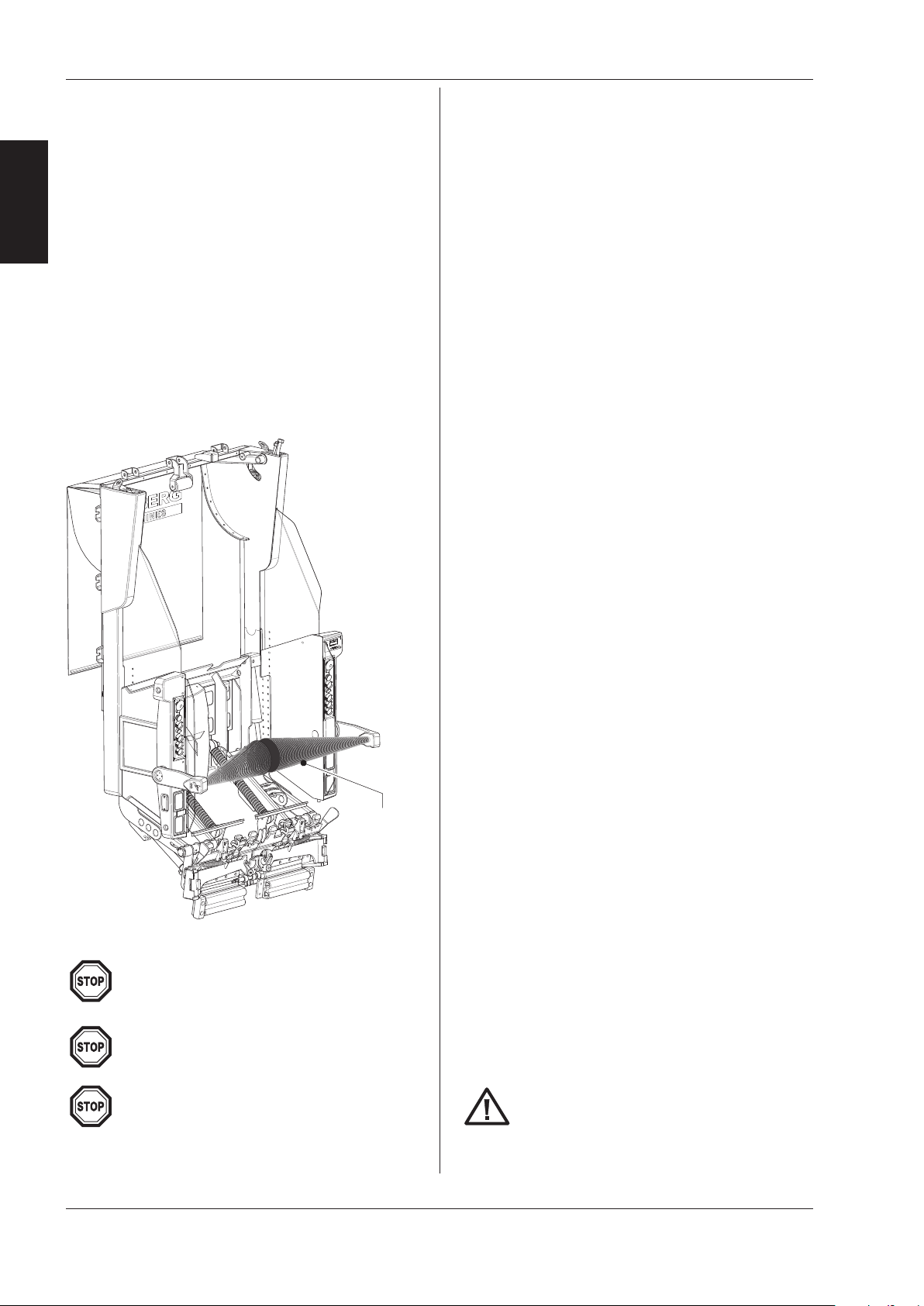

2.2.1 During operation of the bin lift system

•This bin lift has not been designed for throwing in

loose refuse. Should you decide to load loose

refuse, bags or boxes, then ALWAYS SWITCH the

AUTOMATIC function OFF. Always also do this

when removing refuse from the lifting chairs.

•Don’t go between the safety arms if the automatic

function is activated.

•Always switch the automatic function off if for any

reason you need to enter between the safety

arms.

•Make sure that there are no persons in the imme-

diate vicinity of the bin lift during the loading cycle.

•When the bin lift system is operating, under no

circumstances is it permitted to put your hand in

the bin lift system (Risk of injury).

•In the event of danger immediately press the

nearest emergency stop switch

(see chapter Safety provisions 2.4).

•Check that there are no foreign objects in or

between the bin lift system that could obstruct its

working.

•Compacting may not be carried out when there

are objects sticking out of the throw-in opening.

•Don’t use the bin lift system in situations where

there is poor visibility of the bin lift.

•Never use the bin lift system on a very uneven

surface.

•The bin lift system may not be driven up against a

bin/container or a pile of refuse.

•Take account of the heating of the hydraulic oil.

This can become 40°C warmer than the environ-

ment. As a result, the pipes and hoses can cause

light burns at high ambient temperatures.

•It is not permitted to work with bin/container

types other than those stated in the manual.

•Nothing should protrude from the bin and only

bins whose lids are fully closed should be emptied.

•Don’t empty damaged bins/containers. These can

cause problems.

•Overweight bins/containers should be removed

from the bin lift system:

max. lifting capacity 2-wheel bins: 1700N (170kg)

max. lifting capacity 4-wheel cont.: 5000N (500kg)

•Check that the bin/container is positioned cor-

rectly on the pick-up comb before emptying it.

•Let go of the bin/container as soon as it is lifted.

•It is expressly forbidden to ‘manually’ assist the

lifting cycle by hand.

•Only apply extra shaking if there is a need for this.

•Only take the bin/container away when the bin lift

has come to a standstill and the bin/container is

back on the ground.

•Place empty bins/containers where they will not

cause a danger to other road users.

•It is forbidden to empty bins/containers containing

hazardous and/or radioactive substances.

•It is forbidden to empty bins/containers containing

smouldering or burning substances.

•Never walk backwards in the direction of the bin

lift system.

•Two bin presenting and/or taking at a time by one

person should be kept to a minimum.

•A bin may only be offered to the bin lift system

when held by the handle bars.

•Always push a 2-wheel bin to the bin lift with two

outstretched arms.

•Never bend your body over the bin when offering

it to the bin lift.

•Under wintry conditions, if the bin lift is blocked

with large amounts of ice or snow deposits, the

sensors may become concealed or the bin clam-

ping mechanism may become clogged up.

Apply emergency stop switch prior to cleaning.

Clean these parts and keep as dry as possible, for

example with a broom. Never clean the bin lift

using defrosting liquids!

2.2.2 During maintenance and repair

•Maintenance and carrying out of repairs is only

permitted for qualified technical personnel.

•Any faults detected should be corrected before

the bin lift system is used.

•During maintenance and repair work switch off

the bin lift system (switch off the engine of the

refuse collection vehicle and the main power

switch).

•During repair work it must be made impossible

for unintentional switching on to occur, therefore

remove the ignition key from the ignition switch

(keep on your person).

Keep a minimum distance of 2.5 meter

between the bin lift and objects which are

located behind the bin lift system. This is to

avoid a dangerous situation in case that a

bin/container falls from the pick-up comb.