EN - 6

Read, understand, and followall instructions in

the manual and on the machine before

starting. Understand:

• How to operate all controls

• The functions of all controls

• How to STOP in an emergency

DO NOT attempt to start your engine until you

know what the controls do and how they work.

DO NOT tilt trimmer when starting it.

Keep feet away when starting engine.

DO NOT operate trimmer unless trimmer

shield and trailing shield are installed. Objects

may be picked up and thrown causing damage

or personal injury.

NEVER use wire or wire-rope in place of the

cutting line. It can break off and become a

dangerous projectile. Use only flexible, non-

metallic line recommended by Ariens.

ALWAYS keep trimmer head in contact with

the ground while operating.

Take all possible precautions when leaving

unit unattended.

ALWAYS shut off engine and disconnect spark

plug wire to prevent accidental starting or

unauthorized use.

Stop engine if anyone enters the work area.

NEVER attempt to make any adjustments to

unit while engine is running (except where

specifically recommended). Stop engine,

disconnect spark plug wire and wait for all

moving parts to stop before servicing.

DO NOT make cutting height adjustments

while the engine is running.

If you strike an object, or if equipment vibrates

abnormally, stop engine at once, wait for

moving parts to stop and disconnect wire from

spark plug. Repair any damage before

restarting unit.

ALWAYS shut off engine, allow trimmer head

to stop and disconnect spark plug wire before

clearing clogs or cleaning unit.

DO NOT transport machine while engine is

running.

To reduce fire hazard and overheating, keep

equipment free of grass, leaves, debris or

excessive lubricants.

Use extra care when approaching blind

corners, shrubs, trees, or other objects which

may obscure vision.

DO NOT trim at too fast a rate. DO NOT

change engine governor setting or over-speed

the engine.

Do not operate trimmer on gravel or on loose

material such as sand. Stop trimmer when

crossing gravel drives, walks, or roads to

prevent damage or injury from thrown objects.

DO NOT pull trimmer backwards unless

absolutely necessary. Look down and back,

especially for small children, before and while

moving backwards.

DO NOT operate on steep slopes.

NEVER leave unit unattended on a slope.

Chock wheels if parking on a slope.

Trim across the face of slopes, never up and

down. Be especially cautious when changing

direction on slopes.

This product is equipped with an internal

combustion engine. DO NOT use on or near

any unimproved, forest or brush covered land

unless the exhaust system is equipped with a

spark arrestor meeting applicable local, state

or federal laws. A spark arrestor, if used, must

be maintained in effective working order by the

operator. See your Ariens Dealer or engine

manufacturer’s service center.

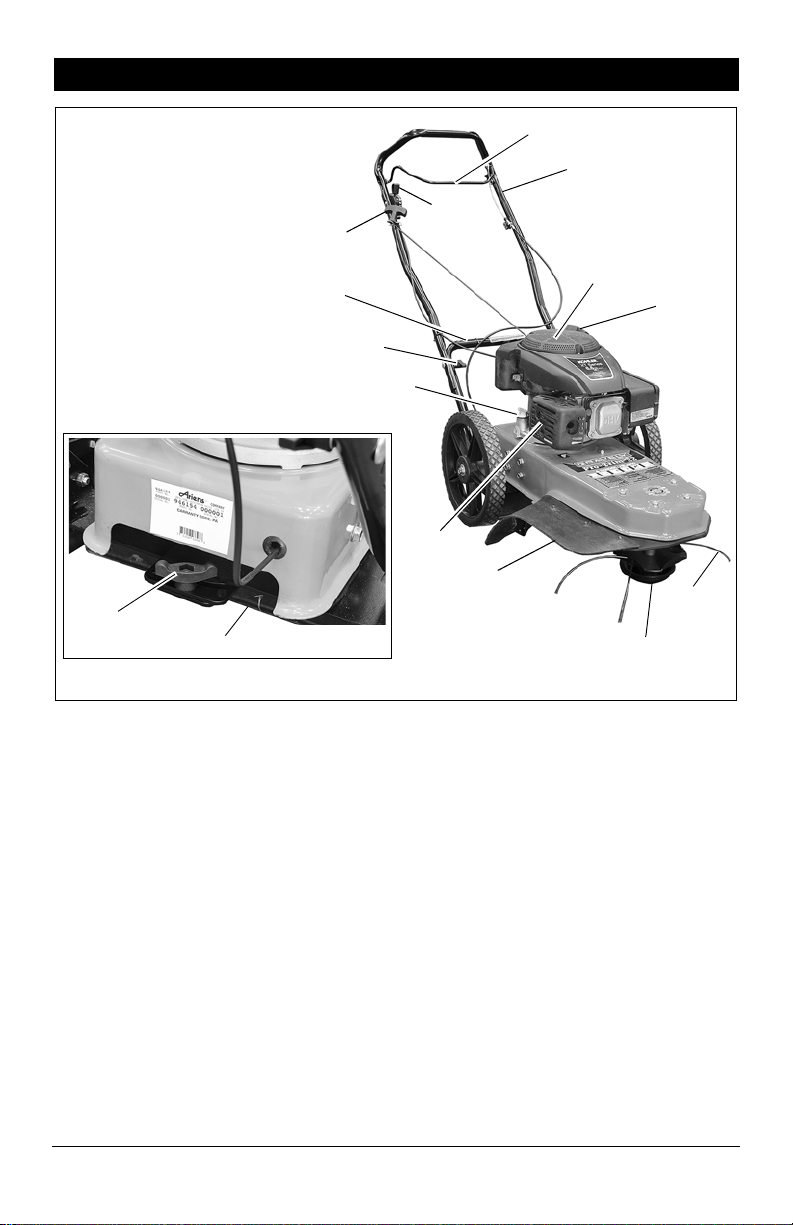

Emission Control System Certification

Label

NOTE: Tampering with emission controls and

components by unauthorized personnel may

result in severe fines or penalties. Emission

controls and components can only be adjusted

by EPA and/or CARB authorized service

centers. Contact your Ariens Equipment

Retailer concerning emission controls and

component questions.

Fuel is highly flammable and its vapors can

explode. ONLY use approved fuel containers.

• NO Smoking!

• NO Sparks!

• NO Flames!

• Allow engine to cool before filling fuel tank.

Never fill containers inside a vehicle or on a

truck or trailer bed with a plastic liner. Always

place containers on the ground away from

your vehicle before filling.

When practical, remove gas-powered

equipment from the truck or trailer and refuel it

on the ground. If this is not possible, then

refuel such equipment on a trailer with a

portable container, rather than from a gasoline

dispenser nozzle.

Keep the nozzle in contact with the rim of the

fuel tank or container opening at all times until

fueling is complete. Do not use a nozzle lock-

open device.

Check fuel supply before starting engine.