4

1.2 Safety and Warning Notes

This device must be properly installed,

started up, and operated only by

qualified technicians.

Always verify no voltage is present

before beginning to work.

Ensure correct wiring connection and

safety regulation compliance to

protect against electric shock.

Connect the protection conductor

terminal “PE” with ground.

Cover terminals’ area after installation

to avoid accidental contacts with live

parts (e. g., installation in control

Do not disconnect Equipment unless

power has been switched off or the area is

Before servicing, disconnect both Mains

and the energy storage to de-energize the

Do not place flammable or exploding

material nearby the device.

To reduce the risk of fire, connect only

to a circuit provided with a maximum

branch circuit overcurrent protection

in accordance with the Norms

To reduce the risk of fire, replace only

NOTE: Battery Connections

When batteries are being connected,

check for correct polarity. Make sure not

to short circuit the battery terminals.

Copper cables must be used for

operating temperatures above 75 °C.

Refer to the associated table for the

connection parameters, such as the

necessary stripping length for the

wiring with and without ferrule (see

section Wire cross sections).

General Installation Notes

National safety and accident

prevention guidelines must be

followed according to UL508 or

UL60950.

Assembly and electrical installation

must correspond to the state of the

art.

The DC-UPS is a built-in device. The

protection class of the device is IP20. It

is meant to be installed in a clean and

dry environment.

Protect the device against foreign

bodies penetrating it, e.g., paper clips

or metal parts.

The device must be installed in a

control cabinet that can be locked

and only opened by specialist staff.

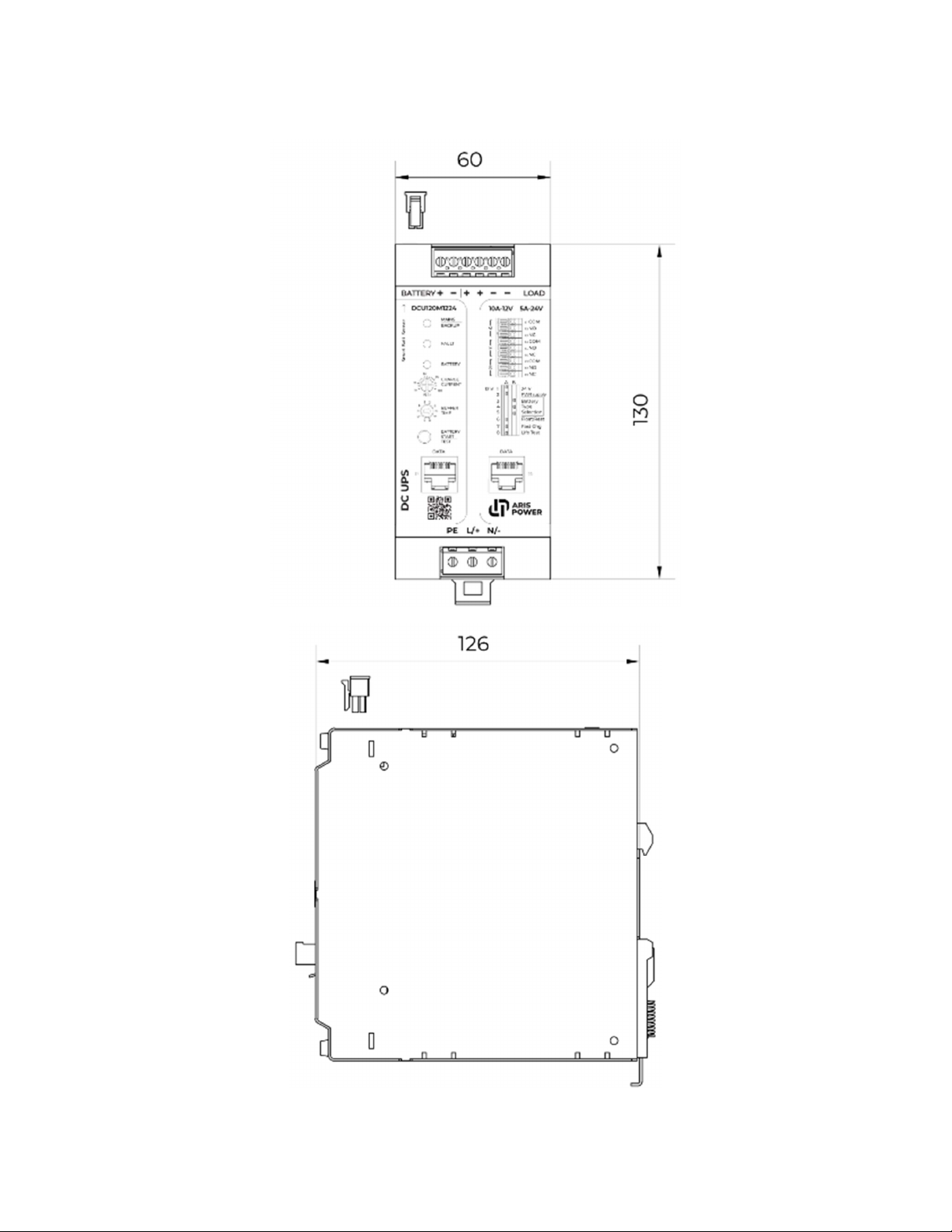

Vertical mounting is the normal and

only authorized mounting position

Observe mechanical and thermal

Install a switch/circuit breaker close to

the device at the Mains input, Load

output and at the battery terminals

which are labeled as the

disconnecting device for this device.

Ensure that the primary-side wiring

and secondary-side wiring are the

correct size and have sufficient fuse

protection.

Do not disconnect the fuse and/or

battery connection when in hazardous

locations.

Use current-limited source or suitable

fuse.

The switching outputs are active

outputs according to SELV. These may

only be operated on permitted SELV

Repairs may only be carried out by the

manufacturer. The warranty no longer

applies if the housing is opened.

The device may only be used for its

intended use.

Improper use invalidates the device

protection.

Keep these instructions in a safe place

– it contains important safety notes

which must be observed during

installation and maintenance of the

UPS devices and batteries.

Both the ambient temperature and

heat losses due to the load operation

may overheat the device housing

surfaces.

Ensure sufficient convection

(minimum gap above/below: 50 mm),