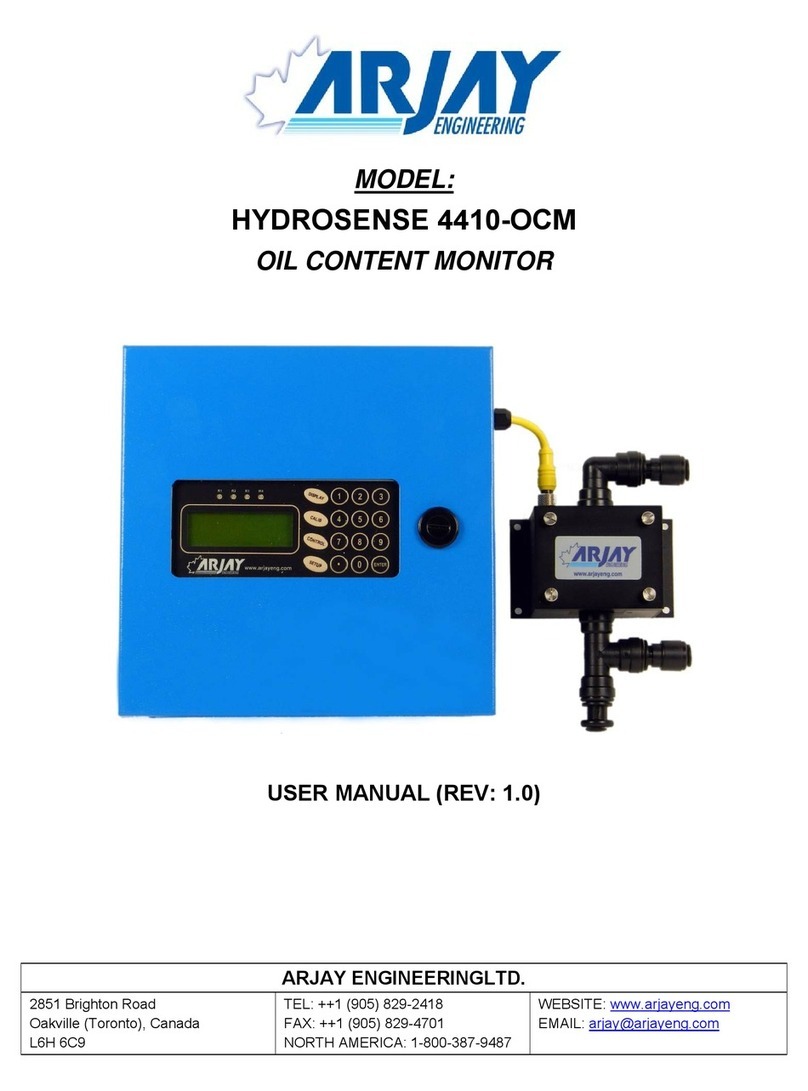

HYDROSENSE 4410-OCM-X Revision 1.0 Page 3 | 29

TABLE OF CONTENT

NOTICE Please read the Installation Notes (4.1) prior to locating and mounting

the instrument.

1.0 SPECIFICATION .............................................................................................................. 5

2.0 USE HAZARD INFORMATION......................................................................................... 7

3.0 INSTRUMENT OVERVIEW .............................................................................................. 8

3.1 Features .......................................................................................................................................... 8

3.2 Description ...................................................................................................................................... 8

4.0 INSTALLATION................................................................................................................ 9

4.1 Hydrosense Installation Notes ......................................................................................................... 9

4.2 Unit Installation .............................................................................................................................. 11

4.3 Glossary of Symbols ..................................................................................................................... 11

4.4 Permanent Power Connection (AC Powered Model Only) ............................................................ 12

4.5 Electrical Installation ...................................................................................................................... 12

5.0 STARTUP AND SETTINGS............................................................................................ 13

5.1 Notes on Value Entry .................................................................................................................... 13

5.2 Password Protection ..................................................................................................................... 14

5.3 Power-Up Display .......................................................................................................................... 14

6.0 CONTROL SETUP.......................................................................................................... 15

6.1 Relay Settings <1> ........................................................................................................................ 15

6.1.1 Setpoint <1> ...................................................................................................................... 15

6.1.2 Time Delay On <2> ........................................................................................................... 15

6.1.3 Relay Enable / Disable <3> OR <4> ................................................................................. 15

6.1.4 Relay Failsafe <5> ............................................................................................................ 16

6.2 mA Output Settings <2> ................................................................................................................ 16

6.2.1 4-20mA Out OR 0-20mA Out <2> ..................................................................................... 16

6.2.2 mA Direct OR Inverse <3> ................................................................................................ 16

6.3 Tools <3> ...................................................................................................................................... 16

6.3.1 Relay Test <1> .................................................................................................................. 16

6.3.2 mA Output Test <2> .......................................................................................................... 16

7.0 SETUP (OPERATION AND DIAGNOSTICS) (<SETUP> KEY)...................................... 17

7.1 System Settings <1> ..................................................................................................................... 17

7.1.1 Net ID <1> ......................................................................................................................... 17

7.1.2 Filter <2> ........................................................................................................................... 17

7.1.3 Units <3> ........................................................................................................................... 17

7.1.4 Password <4> ................................................................................................................... 17

7.1.5 More <5> ........................................................................................................................... 17

7.1.6 mA Output Trim <1> .......................................................................................................... 17

7.1.7 Decimal Point <2> ............................................................................................................. 17

7.2 Diagnostics <3> ............................................................................................................................. 18

7.2.1 Process Value <1> ............................................................................................................ 1 8

7.2.2 Calibration Data <2> ......................................................................................................... 1 8

7.2.3 More <4> ........................................................................................................................... 18

7.2.4 SN / HWRev <3> ............................................................................................................... 1 8

7.3 Date / Time Setup <4> .................................................................................................................. 18