Armeka Engineering A-760 User manual

Resistance meter А-760

1

Resistance meter

A-760

OPERATING MANUAL

Operating manual

2

Resistance meter

A-760

OPERATING MANUAL

1. Introduction

1.1. General

1.1.1. The present Operating manual is designed for the user coming in contact with resistance

meter А-760 (further – unit).

1.1.2. The Operating manual contains important information about the unit and operating

instructions.

1.1.3. There can be some small variations which are not mentioned in the present Operating

manual due to the constant work on improving reliability and operating characteristics of

the unit.

1.2. Description

1.2.1. The present unit, produced by Armeka Engineering, is used for measuring the resistance

of worksurfaces and flooring and is in accordance with ESD Association standards S4.1

(worksurface – resistance measurements) and S7.1 (Resistive Characterization of

Materials–Floor Materials).

1.2.2. The unit is easy to use and of high operating reliability.

1.3. Specific features

1.3.1. Unlike the competitive products, the present unit provides strict concordance to the

standards. The user gets the result, which allows valuing the quality of ESD safe

equipment and deviations from the standard. It saves the time and improves the quality

of testing.

1.3.2. The unit provides measurement of resistance at two voltages, which allows to measure

resistance from 1000 ohm to 100 Gohm.

1.3.3. Low resistance measurements allow high accuracy control of electrodes. This increases

the reliability of measurements.

1.3.4. Unique circuit allows voltage on electrodes not less than 100 V when measuring

resistance from maximum to 1 mega-ohm and to decrease the lower level of resistance.

1.3.5. Low power consumption allows using only standard low voltage batteries.

1.3.6. The unit is performed in two models “STANDARD” and “EXPERT”. The main

difference is in the construction of electrodes (the construction of electrodes in model

“EXPERT” is several times lighter).

Resistance meter А-760

3

2. Safety regulations

The present unit may be operated by the stuff who has been familiar with the present

operating manual and instructions on safety regulation. When operating the unit high voltages

can occur. It can cause unpleasant feelings due to improper use of the unit. By observing the

following instructions the user will considerably minimize the risk of electrical hazard. The

present manual contains safety precautions and warnings informing the user of dangerous

actions and working conditions. Observing the present instructions provides safe work of the

stuff and prolongs the service life of the unit.

ATTENTION

•Don’t switch on the unit before all the test electrodes and connecting cables are

connected or while replacing the test electrodes.

•Don’t touch test electrodes while measuring – it can distort measurement results and cause

unpleasant feelings.

•Don’t use the unit with the appliances, which are not specially designed for the use with the

unit.

•Don’t use the unit for measuring alive circuits.

•Circuits of the unit are the source of high voltage.

•The use of accessories, which are not included into the set can negatively influence the

functioning of the unit or cause the risk of hazardous situations.

•The unit may be disabled by incorrect installation of the batteries.

•Test electrodes, used in model “STANDARD”, are rather heavy. Be careful when working

with them.

Operating manual

4

3. Operating elements

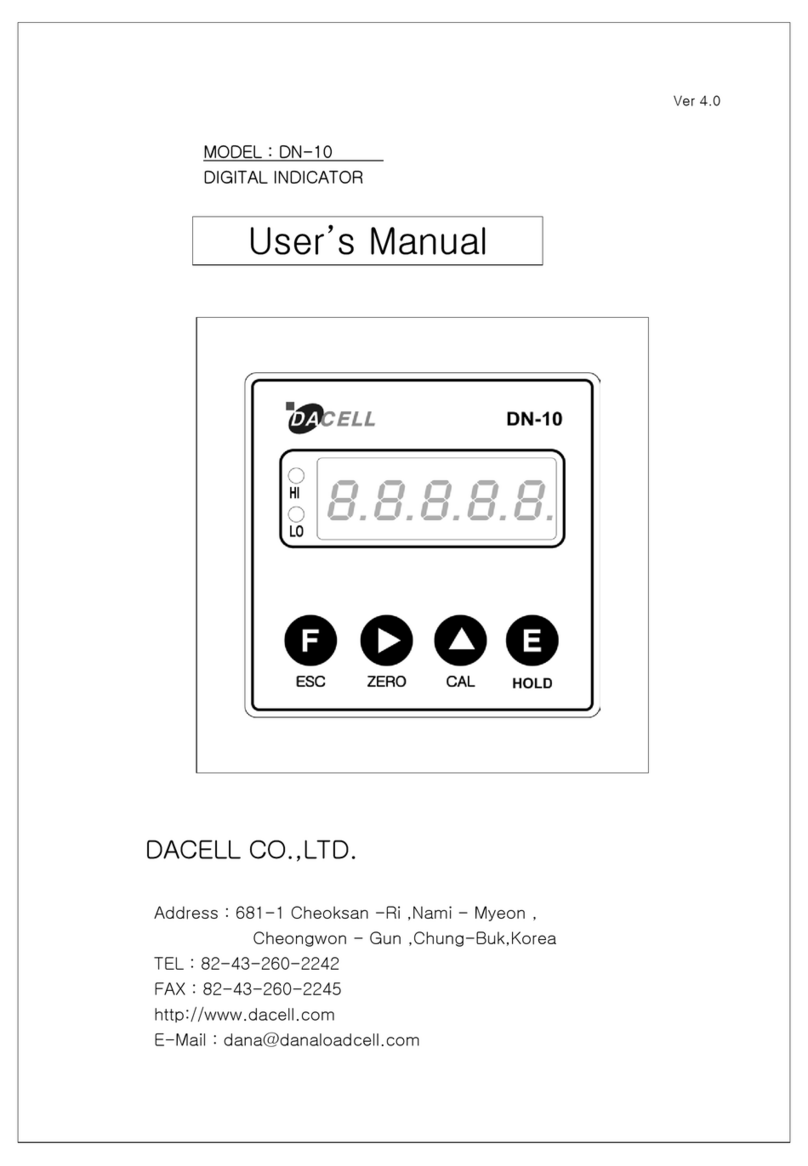

Fig. 1 depicts the unit, operating elements, connectors and indicator scales.

Fig. 1 General view.

3.1. Switch button “On/Off”

When the button is in the position “On”, the power is supplied to the circuit.

ATTENTION

Don’t forget to put the button in the position “Off” after measurements are fulfilled. It

prolongs the life of batteries.

3.2 Button with fixation “Continuity / 10V”

Fixation of the button provides measurement mode at 10 V on test connectors. It allows

either to test the integrity of measuring circuit and the quality of test electrodes or to measure

surface resistance ranged from 100 Ohm to 1 Mohm.

3.3. Button without fixation “Battery test”

This button allows checking the correct work of the circuits and the condition of batteries.

3.4. Button with fixation “100V”

Fixation of the button provides 100 V on test connectors (not less than 100 V on

electrodes at surface resistance 1 Mohm) and measurement of surface resistance ranged from

0,1 Mohm…100 Gohms.

Connection sockets of test

electrodes

Adjusting screw of the

indicator han

d

Button “Battery test”

Button “100 V”

Scale “OHMS at 100 V”

Scale “OHMS at 10 V” and

“Test continuity”

Scale “Battery test”

Button “Continuity / 10V”

Switch button “On/Off”

Resistance meter А-760

5

3.5. Scale “OHMS at 100V”

Read the results of measurements from this scale when testing surfaces by using button

“100V”.

3.6. Scale “Test continuity / 10V”

Read the results of measurements from this scale by fixing button “Continuity / 10V”

when measuring total resistance of test circuit (connecting cables, test electrodes on calibration

plate) or surface resistance.

3.7. Scale “Battery test”

Read the results of measurements from this scale by using button “Battery test”. Values of

the hand characterize working ability of the circuit and the condition of batteries.

3.8. Connection sockets of test electrodes

The sockets are used to connect test electrodes to the unit with the help of connecting

cables (included in the set).

3.9. Adjusting screw of the indicator hand

Allows adjusting the initial position of the hand before switching on.

Working position of the unit - horizontal.

4. Preparation work

4.1. General instructions

Read carefully about each operating element before putting the unit into operation.

Understanding how the unit works will help to avoid unnecessary mistakes and prolong service

life of the unit. The unit has 4 test modes allowing measuring of surface resistance, checking

operating capacity and controlling the condition of electrical characteristics of test electrodes

and connection cables at two different test voltages.

4.2. Working conditions

Working temperature ranges from 0 to 40 Сat relative humidity not more than 75% at

30 С. The unit can be damaged if the values are beyond these limits. The unit shouldn’t be used

in environments with strong electric and magnetic fields. These fields can distort measuring

accuracy.

4.3. Unpacking the unit

Check the packing case for possible damage. In case of possible damage, open the case

and check the unit and accessories. Contact your supplier and forwarder if damages found.

If you consider the unit not to have any damages, read carefully the present manual. Check

all the accessories in the set.

4.4. Battery installation

The unit is delivered with a set of batteries 9 V «Krona» and 1,5 V «ААА», which

guarantee its standard functioning. When installing and replacing the battery:

•make sure that the switch button is in the position «Off»;

•move away the cover from the battery compartment;

•put battery «ААА» in the compartment and connect battery «Кrona» to the socket and place

it and the cables into the compartment so that you can easily place back the cover;

•place back the cover.

4.5. Checking and controlling the initial position of the indicator hand

Operating manual

6

Place the unit on a horizontal surface. Make sure that the switch button is in the position

«Off». The hand of the unit should point at «∞». If it’s the other way, adjust the position of the

hand with the help of adjusting screw» (fig. 2).

Fig. 2. Indicator.

5. Putting into operation

5.1. Checking operating capacity of the unit.

Put the switch button in the position «On», press and hold the button “Battery test”,

which is in the middle. The indicator hand should be in the green zone of the lower scale

“Battery test”.

If the hand during the test is in the yellow zone which is to the left of the green zone in the

lower scale, the batteries should be replaced. If it’s to the right of the green zone, the unit

should be sent to the service center.

ATTENTION

The unit switches on and power supply starts when the switch button is in the

position «On». Don’t forget to put the button into the position «Off» when the measurements

are fulfilled.

5.2. Checking test electrodes and connecting cables

•put the electrodes on a flat surface as it’s shown on fig. 3 and hold the upper electrode by the

handle (model “STANDARD”);

•put the electrodes on a flat surface as it’s shown on fig. 4 and press the upper electrode so

that the free parts sink in the frame. (model “EXPERT”);

•connect the electrodes to input sockets with the help of connecting cables;

•put switch button in the position «On»;

•press the button «Test Continuity / 10V»;

The indicator hand should be in the green field of the middle scale.

Indicator

hand

Indicator adjusting

screw

Resistance meter А-760

7

Fig. 3. Connection of test electrodes to the unit, model “STANDARD”.

If the indicator hand is in the yellow zone, the unit shouldn’t be used, it should be

sent to the service centre.

5.3. Test voltage 10 V

•place the electrodes on the surface to be measured. The surface should be clean to provide

the optimal value of the transfer resistance between the electrodes and the surface;

•put the switch button in the position «On». Press the button «Test Continuity / 10V»;

•read the values from the middle scale;

•put the switch button in the position «Off».

Electrodes (included in the

set

)

Connection cables

(

included in the set

)

Operating manual

8

Fig. 4. Connection of test electrodes to the unit, model “EXPERT”.

5.4. Test voltage 100 V

•if value of surface resistance on scale 10 V is higher than 1 mega-ohm, it’s necessary to

repeat measurements at voltage on test electrodes equal to 100 V;

•put the switch button in the position «On». Press button «100V»;

•read the values from the upper scale;

•put the switch button in the position «Off».

6. Testing

It’s necessary to check and calibrate the unit and electrodes not less than once a year in a

service centre to guarantee the quality of measurements.

Warranty period is 1 year.

7. Maintenance

•the unit doesn’t contain spare parts, demanding maintenance during the operation except

batteries. The unit’s housing and electrodes may be cleaned with special rags for computer

equipment. Contact surface of electrodes should be clean. Avoid direct sun beams on the

contact surface.

•use a packing case for storage and transportation of the unit;

•in case of improper work of the unit don’t try to repair it, it cancels the warranty. Send the

unit to the service centre. The address is given below.

Electrodes (included in the

set

)

Connection cables

(

included in the set

)

Resistance meter А-760

9

8. Storage regulations

8.1. short-time storage

The unit may be stored indoors for a short period (warranty storage) if the following

conditions are observed:

•environmental temperature from 10°Сto + 70°С;

•relative humidity up to 75% at temperature +30°Сand below without condensation of

moisture;

•relative humidity up to 80% at temperature +25°Сand below without condensation of

moisture;

•short-time storage up to 12 months.

8.2. Long-time storage

Long-time storage indoors if the following conditions are observed:

•environmental temperature from +5°Сto +40°С;

•relative humidity up to 80% at temperature +25°Сand below without condensation of

moisture.

Long-time storage with packaging on up to 10 years, if all conditions are observed.

It’s necessary to switch on the unit not less than once a year to check its operating ability.

9. Delivery set includes

•А-760 Resistance meter with a set of batteries;

•А-760 – 1 Test electrode, model “Standard” – 2 pieces;

•А-760 – 2 Test electrode, model “Expert” – 2 pieces;

•А-760 – 4 Connecting cable – 2 pieces;

•А-760 – 5 Metal plate for checking test electrodes;

•А-760 – 6 Packing case for storage and transportation, model “Standard”;

•А-760 – 7 Packing case for storage and transportation, model “Expert”;

•Operating manual;

•Packing crate.

10. Technical data

•Dimensions and weight of the unit: 170х85х35 mm, 300 g.;

•Dimensions and weight of an electrode: 133х63хmm, 2,5 kg±10%;

•Length of the connecting cable not less than 1500 mm;

•Dimensions and material of a metal plate for testing electrodes 150х65х0,5 mm, steel;

•Test voltage up to 116 V;

•Measuring accuracy of surface resistance ±5% at 100V;

•Measuring accuracy when testing electrodes and connecting cables ±5% at 10V;

•Measuring range 10 V – 103…106 Ohm;

•Measuring range 100 V – 104…1011 Ohm;

•Standard power supply batteries: «Krona», 9V and «ААА», 1,5V;

Operating manual

10

11. Contact information

Manufactor: Armeka Engineering ltd

Kilonkallio 3-5, Fin-02610 Espoo, Finland.

http://www.armekaengineering.com

Service centre in Russia: NPF «DIPAUL»

Russia, 197376, Saint-Petersburg, 23a Professora Popova street, office 15-n

Tel./fax (812) 325-1478

http://www.dipaul.ru

Table of contents

Other Armeka Engineering Measuring Instrument manuals