EG&G SOLOIST-U0300 Service manual

SOL

OISTTM

Alpha

Spectrometer

Operating

and

Servíce

Manual

p

lele

Printed

in

U.S.A.

EG&G

ORTEC

Part

No.

740180

4111

0693

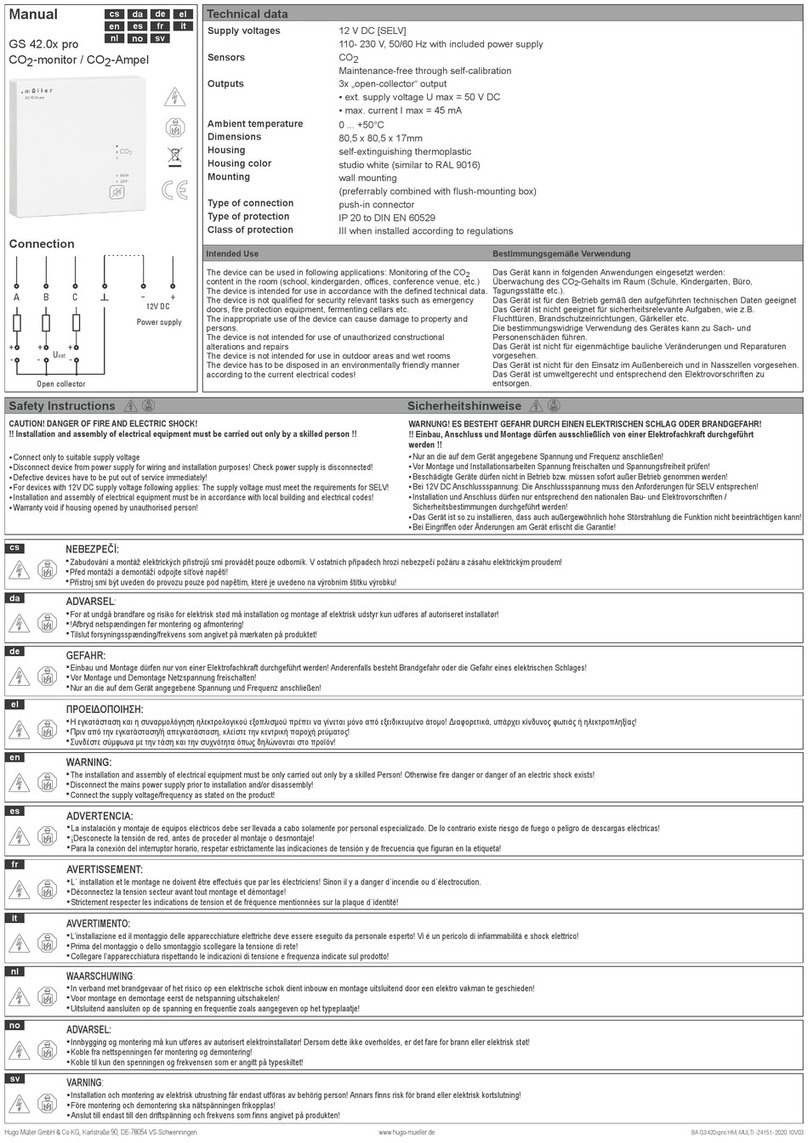

Manual

Revision

A

SOLOIST,

ULTRA-AS,

ULTRA, ALPHAMAT,

and

Ruggedized are

trademarks

of

EG&G

ORTEC.

®Microdot

is

a

registered

trademark

of

Malco/Microdot.

®Swagelok

is

a

registered

trademark

of

Crawford

Company.

III

CONTENTS

WARRANTY.

v

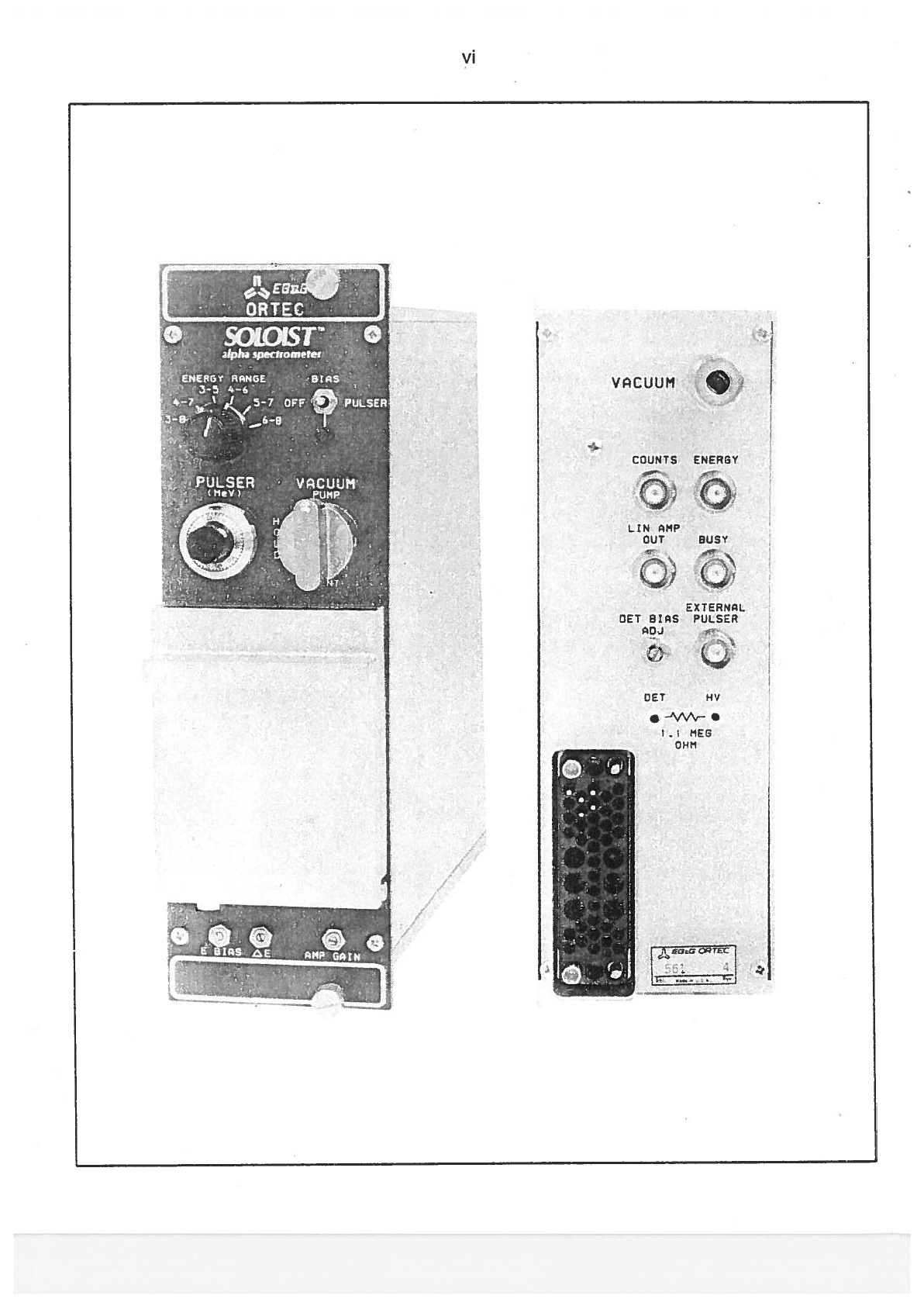

PHOTOGRAPH

vi

1.

DESCRIP1YON

1

2,

SPECIFICATIONS

2.1. PERFORMANCE

2.2.

VACUUM

CHAMBER

2.3.

CONTROLS

2.4.

INPUTS

2.5. OUTPUTS

2.6.

ELECTRICAL

AND

MECHANICAL

2.7.

ACCESSORIES

3

3

3

3

4

4

4

4

6

6

7

7

8

8

8

4.

OPERATION

4.1.

OPERATING

PUMP/HOLDNENT

VALVE

4.2.

SAMPLE

INSER1iON

4.3.

RESOLUTION

MEASUREMENI

AND

CALIBRATION

5.

THEORY

OF

OPERATION

5.1.

SOLOIST

ALPHA

SPECTROMETER

.INEAR

AMPLIFIER

SCHEMATIC.

6.

MAINTENANCE

AND

SERVICE

6.1.

DECONTAMINATION

6.2.

SOLOIST

CHAMBER

REMOVAL

AND

REPLACEMENT.

6.3.

TROUBLESHOOTING

GUIDE

PRINTED

WIRING

BOARD

(PWB)

ASSEMBLY

DRAWINGS

729890

-

ALPHA

SPECTROMETER

729940

-

LINEAR

AMPLIFIER

SCHEMATTCS

761250

-

ALPHA

SPECTROMETER

764030

-

LINEAR

AMPLIFIER

Fig.

1.1.

Fig.

3.1.

Fig.

3.2.

Fig.

3.3.

Fig.

4.1.

Fig.

5.1.

Fig.

6.1.

1

6

7

8

9

11

14

3.

INSTALLATION

3.1.

DETECTOR

SETUP

3.2.

CONNECTION

TO

POWER

3.3.

VACUUM

CONNECTION

3.4.

SIGNAL

CONNECTIONS

3.5.

ENERGY OUTPUT

FULL-SCALE

ADJUSTMENT

(Other than

10

V).

3.6.

LINEAR

AMP

OUTPUT

FULL-SCALE

ADJUSTMENT

(Otherthan

70V).

11

12

13

13

13

15

LIST

OF FIGURES

A

Simplified Block

Diagram

of

the

SOLOIST

Electronics

Position

of

Polarity

Switches

for

Bias

and

Amplifier

Suggested

Vacuum

Connections

for

the

SOLOIST

Spectrometer.

SignaI

Connections

PUMP/HOLDNENT

Valve

Detailed

Block

Diagram

of

the

SOLOIST

Alpha

Spectrometer

Vacuum

Chamber

and

Coaxial

Cable

Connection

iv

1

v

Standard

Warranty

for

EG&G

ORTEC

Instruments

EG&G

ORTEC

warrants

that

the

items

wili

be

delivered

free

trom

defects

in

material

or

workmanship.

EG&G

ORTEC

makes

no

other

warranties,

express

or

impiied,

and

specificaiiy

NO

WARRANTY

OF

MERCHANTABILITY

OR

FITNESS

FOR

A

PARTICULAR

PURPOSE.

EG&G

ORTEC’s

exclusive

iiability

is

limited

to

repairing

ar

replacing at

EG&G

ORTEC’s option,

items

found

by

EG&G

ORTEC

to

be

defective

in

workmanshíp

ar

materiais

within

one year

from

the

date

of

deiivery.

EG&G

ORTEC’s

liability

on

any

claim

of

any

kind,

including

negligence,

Ioss,

ar damages

arising out

of,

connected

with,

ar

from

the

performance ar

breach

thereof,

ar

from

the

manufacture,

saie,

deiivery,

resale,

repair,

or

use

of

any

item

ar

services

covered

by

this

agreement

or

purchase

arder,

shaii

in

no

case

exceed

the

price

aliocabie

ta

the

tem

ar

service

furnished

ar

any part thereof

that

gives

rise

to

the

claim.

in

the

event

EG&G

ORTEC

faiis

to

manufacture

ar

deliver

items cailed

for

in

this

agreement

or

purchase

arder,

EG&G

ORTEC’s

exclusive

liability

and

buyer’s

exclusive remedy

shail

be

release

of

the

buyer

fram

the

obligation

to

pay

the

purchase

price.

in

no

event

shail

EG&G

ORTEC

be

liable for

speciai

ar

consequential

damages.

Quality

Control

Before

being

approved

for

shipment,

each

EG&G

ORTEC

instrument must

pass

a

stringent

set

of

quality

contrai

tests

designed

to

expose

any

flaws

in

materiais

ar

workmanship.

Permanent

records

of

these

tests

are

maintained

for

use

in

warranty

repair

and

as

a

saurce

ot

statisticai

information

for

design

impravements.

Repair

Service

if

it

becomes necessary

to

return this

instrument

for

repair,

it

is

essential

that

Customer

Services

be

cantacted

in

advance

of

its

return

so

that

a

Return Authorization

Number can

be

assigned

ta

the

unit.

Also,

EG&G

ORTEC

must be

informed,

either

in

writing,

by

teiephone

[(615)

482-4411],

by

telex

(6843140)

ar

by

facsimiie

transmissian

[(615)

483-0396],

af

the

nature

af

the

fauit

aí

the

instrument

being

returned

and

af

the

model,

serial,

and

revisian

(“Rev’

on

rear

panei)

numbers.

Failure

to

do

so

may

cause

unnecessary

deiays

in

getting

the

unit

repaired.

lhe

EG&G

ORTEC

standard

procedure

requires

that

instrurnents returned

for

repair

pass

the

sarne

quaiity

contrai

tests

that

are

used

for

new

praductian instruments.

instruments

that

are

returned

should

be

packed

sa

that

they

wiii

withstand

nor

mal

transit

handiing and

must

be

shipped

PREPAID

via

Air

Parcei

Post

ar

Uníted

Parcei

Service

to

the

nearest

EG&G

ORTEC

repair

center. The

address

iabei

and the

package

shauid

inciude

the

Return

Authorization

Number

assigned.

instruments

being

returned

that

are

damaged

in

transit

due

to

nade

quate

packing

wiii

be

repaired

at

the

sender’s

expense,

and

it

wiii

be the

sender’s

responsibiiity

to

make

ciaim

with

the

shipper. instrurnents

not

in

warranty

wiii

be

repaired at the

standard

charge

unless

they

have

been

grassiy

misused

ar

mishandied,

in

which

case

the

user

will

be

notified

prior

ta the

repair

being

done.

A

quatation

wiii

be

sent

with

the

notitication.

Damage

in

Transit

Shipments shauid

be

examined

immediately upon

receipt

for

evidence

af

externai

ar

canceaied

dam

age.

lhe

carrier

making

deiivery

shouid

be

natitied

immediateiy aí

any

such

damage, since

the

carrier

is

normaiiy

liable

for

damage

in

shipment.

Packing

materiais,

waybiiis,

and

ather

such

documentation

shauid

be

preserved

in

arder

to

estabiish

claims.

After

such

notificatian

to

the

carrier,

please

notify

EG&G

ORTEC

aí

the

circumstances

SO

that

assistance

can

be provided

in

making

damage

claims

and

in

praviding

repiacement

equipment,

if

necessary.

yi

CQUNTS

ENERGV

LIN

AMP

OUT

BUSY

EXTENc

DET

8S

PULSER

OET

NU

•

-•\M—

ME

OHM

VACUUM

1

EG&G

ORTEC

SOLOISTTM

Alpha

Spectrometer

1.

DESCRIPTION

The

SOLOIST

is

an

integrated

spectrometer

for

measuring

low-activity

sampies

that

decay

by

alpha

particle

emission.

lt

incorporates

ali

the

necessary

functions

within

a

NIM-standard

doublewidth

module.

The

module

includes

vacuum

chamber, detector,

bias

supply

for

the

detector,

complete

amplifying

chain

(preamplifier,

amplifier,

and

biased

amplifier),

and

calibration

pulser.

The

SOLOISI

offers

three

flexible

methods

for

recording

the

alpha

emission

activity.

lhe

simplest

is

to

record

the

gross

counting

rate

above

the

2.5-MeV

threshold

using

an

external

counter

and

timer.

lo

achieve

much

lower

detection

Iimits,

the

linear

amplifi

er

output

can

be

fed

to

a

multichannel

puise-height

analyzer

(MCA)

for

quantitative

analysis

of

specific

isotope

peaks

in

the

0-

to

10-MeV

energy

spectrum.

lhe

biased

amplifier

output

of

the

SOLOIST

offers

selection

ot

a

restricted

energy range

(containing

only

the

peaks

of

interest)

for

analysis

on

the

MCA.

lhis

feature

allows a

larger

number

of

aipha

spectrome

ters

to

be

multiplexed

into

the

limited

memory

size

of

asingle

MCA.

A

front-panel

switch

provides

6

seiec

table energy

ranges

at the

biased

amplitier

output

(3

to

8

MeV,

4

to

7

MeV,

3

to

5MeV,

4

to

6

MeV,

5

to

7

MeV,

and

6

to

8

MeV).

Three

front-panei

adjust

ments

permit

precise

calibration

on

any

selected

energy range.

machined

to

dose

tolerances,

before

being

nickel

plated

to

ensure

easy

decontamination.

In

the

event

of

severe

contamination,

the

chamber

may

be

easily

isolated

from

vacuum,

and

then

removed

trom

the

module.

A

compressed,

high-performance

O-ring,

retained

in

a

dove-taiied

groove

in

the

face

of

the

chamber,

provides

an ultra-reliable

vacuum

seal

for

the

chamber

door. Nickel-plated

brass

sample

trays

slide

into

the

chamber

to

provide

an

adjustable

and

precisety

reproducible

sample-to-detector

spacing.

lrays

are

available

to

handle

sample

sizes

from

13 mm

(0.5

ín.)

to

51

mm

(2

in.), with

sample-to

detector

spacing

seiectable

from

1

to

41

mm

in

incre

ments

of

4mm.

lhe

front-panei

PUMP/HOLDNENI

vaive

makes

it

easy

to

insert,

count,

and remove

sam

pies

without

disturbing

the

vacuum

on

other

SOLOIST

chambers

attached

to

the

sarne

vacuum

pump.

A

standard

SwageIok

fitting

on

the

tear

panei

simplifies

connection

ot

the

valve

and

chamber

to

an

externa!

vacuum

pump.

An

optional pump

station

(Modei

576N676A-PPS)

is

available

for

this

function,

and the

Model 576-VM

Vacuum

Manifold

can

be

added

to

connect

up

to

four

SOLOISI

modules

to

the

sarne

vacuum

pump.

lhe

SOLOIST

is

available

with

an

ULIRA-ASTM

Series

detector

instalied.

lhese

ion-implanted

silicon

detectors

from

EG&G

ORTEC

are

specialiy

designed

The

SQLOIST

includes

a

robust,

Iow-background,

sample chamber.

lhe

chamber

is

cast

in

brass,

then

SwageIok

is

a

registered

trademark

of

Crawford

Company.

Busy

LINEAR

AMPLIFIER

OUTPUT

ENERGY

OUTPUT

COUNTS

QUTPUT

Fig. 1.1.

A

SimpHf

leU

Block Diagram

of

the

SOLOIST

Electronics.

2

and

fabricated

for

Iow-background

applications

in

alpha

spectrometers.

Detector

sizes

up

to

1200

mm2

in

active

area

can

be

accommodated

The

SOLOIST

is

also

available

without

the

detector

to

permit

instal

lation

of

alternative

types

of

silicon

detectors,

such

as

EG&G

ORTEC

RuggedizedTM

R-Series

surface

barrier

detectors,

or

other

ORTEC

surface

barrier

detectors.

A

front-panel

adjustment

and internal

jumpers

accommodate

detectors

requiring

positive or

negative

bias voltage

in

the

range

of

O

to

100

V.

A

variety

of

single-

or

multiplexed-input multichannel

analyzers

are

available

from

EG&G

ORTEC

for

use

with

the

SOLOIST.

Quantitative

alpha-spectroscopy

software

is

also

offered

with

most

of

these

MCAs,

Please

consult

the

appropriate section

of

the

EG&G

ORTEC

catalog

for

further

information

on

these

prod

ucts.

e

3

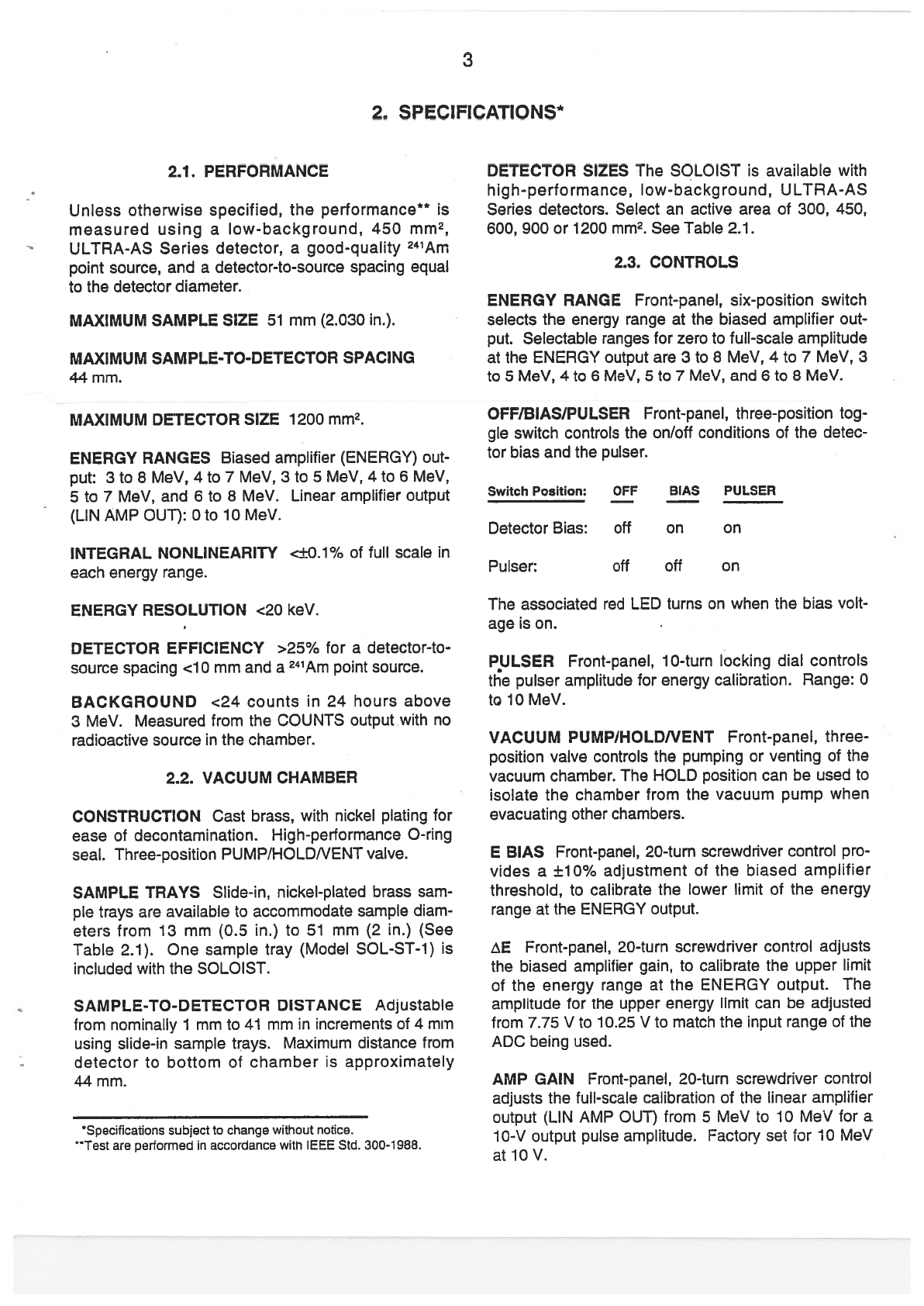

2.

SPECIFICATIONS*

2i.

PERFORMANCE

Unless

otherwise

specified, the

performance**

measured

using

a

low-background,

450

mm2,

ULTRA-AS

Series

detector,

a

good-quaiity

241Arn

point

source,

and

a

detector-to-source

spacing

equal

to

the

detector

diameter.

MAXIMUM

SAMPLE

SIZE

51

mm

(2.030

in.).

MAXIMUM

SAMPLE-TO-DETECTOR

SPACNG

44

mm.

MAXIMUM

DETECTOR

S1ZE

1200

mm2.

ENERGY

RANGES

Biased

amplifier

(ENERGY)

out

put:

3to8MeV,4to7MeV,3to5MeV,4to6MeV,

5

to

7

MeV,

and

6

to

8

MeV.

Linear

amplifier

output

(LIN

ÁMP

OUT):

O

to

10

MeV.

INTEGRAL

NONLINEARITY

<±0.1%

of

fuil

scale

in

each

energy

range.

ENERGY

RESOLUTION

<20

keV.

DETECTOR EFFICIENCY

>25%

for

a

detector-to

source

spacing

<10

mm

and

a

241Am

point

source.

BACKGROUND

<24

counts

in

24

hours

above

3MeV.

Measured

from

the

COUNTS

output

with

no

radioactive

source

in

the

chamber.

2.2.

VACUUM

CHAMBER

CONSTRUCTION

Cast

brass,

with

nickei

plating

for

ease

aí

decontamination.

High-performance

O-ring

seal.

Three-position

PUMP!HOLDNENT valve.

SAMPLE

TRAYS

Slide-in,

nickel-piated

brass

sam

pie

trays

are

available

to

accommodate

sample

diam

eters

from

13

mm

(0.5

in.)

to

51

mm

(2

in.)

(See

Table

2.1).

One sample

tray

(Model

SOL-ST-1)

is

included

with

the

SOLOIST.

SAMPLE-TO-DETECTOR

DISTANCE

Adjustabte

from

nominaIiy

1

mm to

41

mm

in

increments

aí

4

mm

using

slide-in

sample

trays.

Maximum

distance

trom

detector

to

bottom

aí

chamber

is

approximately

44

mm.

*SpecÍfications

subject

to

change

without

notice.

**Test

are

pertormed

in

accordance

with

IEEE

Std.

300-1988.

DETECTOR

SIZES

lhe

SOLOIST

is

available

with

high-performance,

low-background,

ULTRA-AS

Series

detectors. Select

an active

area

of

300,

450,

600,

900

ar

1200

mm2.

See

Table

2.1.

23.

CONTROLS

ENERGY

RANGE

Front-panel,

six-position

switch

selects

the

energy range

at

the

biased

amplifier

out

put.

Selectabie ranges

for

zero

to

fulI-scale

amplitude

at

the

ENERGY

output

are

3

to

8

MeV,

4

to

7

MeV,

3

to

5

MeV,

4

to

6

MeV,

5

to

7

MeV,

and

6

to

8

MeV.

OFF/BIAS/PULSER

Front-panel,

three-position

tog

gte

switch

controls

the

on/off

conditions

aí

the

detec

tor

bias

and

the

pulser.

Switch

Position:

Detector

Bias:

off

Pulser:

BIAS

PULSER

on

on

0ff

off

on

lhe

associated

teU

LED

turns

on

when

the

bias

volt-

age

is

on.

PULSER

Front-panel,

10-turn

locking

dial

controis

the

pulser

amplitude

for

enetgy

calibration.

Range:

O

to

10 MeV.

VACUUM

PUMP/HOLDNENT

Front-panel,

three

position

valve

controis

the

pumping

ar venting

aí

the

vacuum

chamber.

The

HOLD

position

can

be

used

to

isolate

the

chamber

from

the

vacuum

pump

when

evacuating

other

chambers.

E

ElAS

Front-panel,

20-turn

screwdriver

control

pra-

vides

a

±10%

adjustment

of

the

biased

amplifier

threshofd,

to

calibrate the

Iower

lirnit

of

the energy

range

at

the

ENERGY

output.

tE

Front-panel,

20-turn

screwdriver

contrai

adjusts

the

biased

amplifier gain,

to

calibrate

the

upper

limit

of

the

energy

range

at

the

ENERGY

output.

lhe

amplitude

for

the

upper

energy

limit

can

be

adjusted

from

7.75

V

to

10.25

V

to

match

the

nput

range

aí

the

ADC

being

used.

AMP

GAIN

Front-panel,

20-turn

screwdriver

contrai

adjusts

the

fuIi-scale

calibration

of

the

linear

amplifier

output

(LIN

AMP

OUT)

from

5

MeV

to

10 MeV

for

a

1O-V

output

pulse

amplitude.

Factorv

set

for 10

MeV

at

10V.

4

DETECTOR

POLARITY

JUMPERS

(+1—)

Five

print

ed

circuit

board

jumpers

select

the

polarity

ot

the

amplifier

gain

and

the

detector

bias voltage

to

match

the

polarity

of

voltage

required

by

the

detector.

Normally

shipped

in

the

“+“

position

for

ULTRA-AS

Series

detectors.

DET

BIAS

AD]

Rear-panel,

one-turn screwdriver

control

permits

adjustment

of

the

detector

bias

to

the

value

specified

for

the

installed

detector.

Variable

from

O

to

100

V.

Bias

polarity

is

set

to

match the

detector

via

the

Detector

Polarity

Jumpers.

2.4.

INPUTS

VACUUM

Rear-panei vacuum

connector

(Swagelok

connector

for

0,25-in.

CD

tubing)

for

connecting

the

vacuum

chamber

in

the

module

to

a

vacuum

pump.

EXTERNAL

PULSER

Rear-panel

BNC

connector

accepts

external pulser

signals.

lnput

impedance

is

100

Q,

dc-coupled.

lnput

pulse

polarity

must

be

oppo

site

that

of

the

detector

bias

polarity.

2.5. OUTPUTS

COUNTS

Rear-panel

BNC

connector

provides

a

NIM-standard positive

logic

pulse

for

any

detected

particle

having

an

energy

greater

than

2.5

MeV.

Used

for

gross

alpha

counting,

or

routing

in

a

multi

channel

analyzer.

Pulse

width

is

3.5

is.

Output

impedance

is

50

í2,

dc-coupled.

ENERGY

Rear-panel

BNC

connectot

provides the

linear

output

signal

from

the

biased

amplifier

for

con

nection

to

an

ADC

or

multichannel

anaiyzer.

Output

amplitude

range

is

factory

set

for

O

to

÷10

V,

which

corresponds

to

the

energy

ranges

selected

by

the

front-panel

ENERGY

RANGE

switch.

See

E

BIAS

and

zE

controls

for

output

range

adjustment

and

cali

bration.

Output

impedance

is

100

2,

dc-coupled.

LIN

AMP OUT

Rear-panel

BNC

connector

delivers

the

línear

amplifier

output sígnal

for

connection

to

an

ADC

or

multichannel

analyzer.

Factory

adjusted

for

O

to

10

MeV,

corresponding

to

a

0-

to

÷10-V

output

pulse

amplitude.

See

AMP

GAIN

control

for

calibra

tion

adjustment.

Output

pulse

has

a

unipolar,

semi

Gaussian

pulse

shape

with

a

1-lis

shaping

time

con

stant.

Output

impedance

is

100

2,

dc-coupled.

BUSY

Rear-panei

BNC

connector

produces

a

NIM

standard

positive

logic

pulse

whenever

the

module

is

busy

processing

a

pulse. Can

be

supplied

to

an

ADC

or

multichannei

analyzer

to

assist

in

dead-time

corrections

when

dead-time

losses

are

significant.

Output

impedance

is

10

f2,

dc-coupled.

DET/1.1

MEG

OHMJHV

Rear-panel

test

jacks

permit

monitoring

the

voltage

of

the

detector

bias

supply,

and

the

detector

load

current,

The bias

supply

voltage

is

read

at

the

HV

test

jack.

lhe

voltage

measured

between

the

two

test

jacks

permits calculation

of

the

detector

load

current

flowing

through

the

1.1-Mí2

resistor.

2.6.

ELECTRICAL

AND

MECHANICAL

POWER REQUIRED

lhe

SOLOIST

derives

its

power

from

a

NIM-standard

bin/power

supply,

such

as

the

EG&G

ORTEC

Model

4001A/4002A,

or

4001A/4002D.

lhe

power

required

is

+24

V

at

120

mA,

+12V

at 90

mA, —12V

at

45

mA,

and

—24V

at

75

mA.

WEIGHT

Net

2.4

kg

(5.2

lb).

Shipping

3.3

kg

(7.3

lb).

DIMENSIONS

NIM-standard, double-width module

6.90

x

22.13

cm

(2.70

x

8.714

in.)

front

panei

per

DOEIER-0457T.

2.7.

ACCESSORIES

SPARE

CHAMBER

GASKETS

Replacei’hent

O

rings

for

the

vacuum

chamber

door

are

available

in

quantities

ot

10

in

apackage.

See

Table

2.1.

SAMPLE

TRAYS

A

variety

of

slide-in

sample

trays

are

available

to

hold

different

sample

sizes.

See

Table

2.1.

One

SOL-ST-1

sample

tray

is

included

with

the

SOLOIST.

VACUUM

MANIFOLD

lhe

EG&G

ORTEC

Model

576-VM

Vacuum

Manifold

and

Control

is

recom

mended

for

connecting

a

common

vacuum

source

to

four

SOLOIST

modules.

Ask

for

the

576-VM

data

sheet.

PORTABLE

PUMP

STATION

lhe

EG&G

ORTEC

Model

576N676A-PPS

Portable

Pump Station

is

rec

ommended

for

evacuating

the

sample

chamber

in

the

SOLOIST.

The

pump station

is

available

in

both

115-

V

ac

and

230-V

ac

versions,

and

can

be

combined

with

the

Modei

576-VM

Vacuum

Manifold

to

serve

multiple

SOLOIST

modules. The

standard

pump

sta

tion

is

supplied

with

1

m

(40

in.)

of

1-in.

lD

vacuum

hose

for

connection

to

the

576-VM,

and

0.9

m

(36

in.)

of

1/4-in.

CD

vacuum

hose

for

coupling

the

larger

hose

to

the

SOLOIST.

If

different Iengths

are

required,

contact the

factory

for

a

special

order.

See

the

PPS

Portable

Purnp

Station

data

sheet

for

further

description.

MULTICHANNEL

ANALYZERS

WITH

SOFTWARE

The

ENERGY

output

of

the

SOLOIST

is

intended

for

use

with

a

rnultichannel

pulse-height analyzer.

Consult

the

EG&G

ORTEC

catalog

for

the

appropri

ate

single-

or multiplexed-input

rnultichannel

anaiyzer,

and

alpha-spectroscopy

software.

5

REPLACEMENT

DETECTORS

Detectors that

have

been severely contaminated

or

otherwise

damaged

beyond

use

can

be

replaced

by

ordering

a

new

detec

tor

of

the

sarne

size

from

the

ULTRA-AS

Series

of

detectors

Iisted

in

the

EG&G

ORTEC

catalog.

Be

sure

to

specify

the

ULTRA-AS

detector

with

a

B

Mount.

Model

Number

Table

2.1. SOLOIST

Configurations

and

Accessories.

Description

SOLOIST

SOLO1ST-U0300

SOLOIST-U0450

SOLOIST-U0600

5OLO1ST-U0900

SOLOIST-U1

200

Alpha

Spectrometer

without

detector

Alpha

Spectrometer

with

300

mm2,

ULTRA-AS

detector

instated

Alpha

Spectrometer

with

450

mm2,

uLTRA-As

detector

installed

Alpha

Spectrometer

with

600

mm2,

ULTRA-AS

detector

instated

Alpha

Spectrometer

with

900

mm2,

ULTRA-AS

detector

installed

Alpha

Spectrometer

with

1200

mm2,

ULTRA-AS

detector

installed

Accessories

Sample

Tray

for

3/4-in.

(1

9-mm)

and

1in.

(25-mm)

diameter

sampies.

fOne

SOL-ST-1

included

with

each

SOLOIST).

Sampie

Tray

for

1/2-in.

(13-mm)

and

7/8-in.

f22-mm)

diameter

samples

Sampie

Tray

for

1

.25-in.

f32-mm)

and

1

.5-in.

(38-mm)

diameter

samples

Sample

Tray

for

1

.75-in.

(44-mm)

and

2-in.

(51

-mm)

diameter

sampies

Set

of

Sampie

Trays:

One

each

of

ali

four

sizes

(1/2

in.

through

2

in.)

SOL-CG

Spare

gaskets

(O-rings)

for

the

vacuum

chamber

door

(package

ot

10)

576N676A-PPS-1

15

576N676A-PPS-230

576-VM

1

15-V

Portable

Pump

Station

for

the

SOLOIST.

Also

compatible

with

the

576-VM

Vacuum

Manifold.

230-V

Portable

Pump

Station

for

the

SOLOIST.

Also

compatíble

with

the

576-VM

Vacuum

Manitoid.

Vacuum

Manitotd

and

Controi

50L-sT-1

SOL-ST-2

SOL-ST-3

SOL-ST-4

SOL-ST-K

*For

R-Senes detectors

contact

the

factory.

6

3.

INSTALLATION

This

section

describes

the

steps

that

must

be

taken

to

set

up

a

standard

SOLOIST

system.

lhe

necessary

steps

include

detector

setup

and

instaliation,

vacuum

connection,

and output

voltage

adjustment.

3.1.

DETECTOR

SETUP

POLARITY

SWITCH

SETflNGS

Positive

bias

volt-

age

is

required

for

silicon

dioxide-passivated,

ion

impianted

detectors

(such

as

EG&G

ORTEC

ULTRA

AS

Series

detectors)

and

surface

barrier

detectors

(such

as

EG&G

ORTEC

A

Series).

if

the

detectors

were

instaiied

at the

factory,

the

switches

are

aiready

properly

set.

lf

no

detectors

were

installed,

then

the

unit

was shipped

with

positive

bias.

There

are

two

siide

switches

that

must be

changed

when

an

EG&G

ORTEC

Ruggedized

detector,

which

requires nega-

tive

poiarity,

is

used.’

Fíve

piug-in

jumpers

on

the

printed

wiring

board

(PWB)

must

be

set

to

the

correct

polarity

for

the

type

of

detector

in

use.

These

jumpers

are

accessibie

when

the

right

side panei

is

removed

from

the

instru

ment

chassis. These

five

jumpers

are

used

to

seiect

either

positive

or

negative

detector

voitage

polarity

and

the

corresponding correct

ampiifier poiarity.

Positive

bias

is

required

for

EG&G

ORTEC ULTRA

AS

Series,

siiicon

dioxide-passívated,

ion-impianted

detectors.

These

tive

internal

jumpers need

to

be

changed

oniy

when

an

ULTRA-AS or

A-Series

detec

tor

is

repiaced

with

a

Ruggedized

detector,

or

vice

versa.

POLARITY

SELECTION

When

polarity

needs

to

be

changed:

1.

Remove

the

SOLO1ST

Aipha

Spectrometer

module

from

the

bin/power

supply.

2.

Remove

the

side

panei

trom

the

right

side

ot

the

module

(as

viewed

trom

the

front

panei).

3.

Note

the

locations

of

ali

tive

jumpers

on

the

compo

nent

side

of

the

SQLOIST Aipha

Spectrometer

PWB

(Fig.

3.1).

lhe

“+“

and

“—“

orientation

for

each

of

the

jumpers

is

etched

on

the

PWB.

4.

Place

ali

tive

ot

these

jumpers

at

“—“

for

a

Ruggedized

detector,

or

at

“+“

for

aconventionai

sur

Channel

A

Printed

Circuit

ai.to

Detector

Fig.

3.1.

Position

of

Polarity

Switches

for

Bias

and

Amplifier.

face

barrier

detector

or

EG&G

ORTEC

ULTRA-AS

Series,

siiicon

dioxide-passivated,

ion-impianted

detector.

BIAS

VOLTAGE

SETTINGS

lhe

bias voitage

for

each

detector

can

be

adjusted

from

O

to 100

V

using

the

screwdriver

tear-panei DEI

BIAS

ADJ

poten

tiometer.

lhe

unit

is

normaiiy

shipped

with

the

bias

suppiy

set

to

÷50

V.

lhe

vaiue

of

the bias voitage

and

detector

ieakage

current can

be

measured

on

the

reat-panei

test

jacks.

Measure

the

bias

voitage

at

the

“HV”

test

jack,

and

the

detector

leakage curtent

between the

“DET”and

“HV”

test

jacks.

lhe

input

impedance

ot

the

voitmeter must be

10

M2

for

this

measurement.

INSTALLING

THE

DETECTOR

The

ULIRA-AS

Series

detectors

normaliy

used

in

the

SOLOIST

have

a

thin

(500

A)

contact,

ion-impianted

into

the

siiicon

surface.

lhe

contact

is

thus

more

rugged than

that

tormed

by

an

evaporated

goid iayer.

if

the

siiicon

sur

face

is

scratched,

however,

the

detector

wiii

be

dam

aged.

Reasonabie

precautions

shouid,

therefore,

be

taken

when

handling

these

detectors.

1Which

detectors

do

have?

Ali

EG&G

ORTEC

charged-partície

detectors

are

shipped

in

a

piastic

container,

accompanied

by

a

QC

sheet.

Both

bear

the

model

number.

The

first

letter gives

the

mount

type

(always

B

tear

Microdot®,

for

SOLOIST).

The

second

ietter

is

the

detector

type:

R

=

Ruggedized

(negative

bias),

U

=

ULTRA

fpositive

bias),

A

A

Series

(positive

bias).

Edge

Connector

ORTEC

908-2

Five

Jumpers

Preamp

Shield

7

lf

other

types

of

detectors

are

used,

read the

detec

tor’s

instruction

sheet

before

installing

and

using

the

detector.

Then:

1.

Turn

the

detector

ElAS

off

for

the

chamber

into

which

the

detector

is

being installed.

2.

Use

clean

plastic

gioves

and make sure

the

white

protective

cap

for

the

detector

is

ti

piace.

Carefully

align

the

center

pin

in

the

top

of

the

chamber

with

the

center

socket

in

the

detector

connector.

(Any

mis

alignment

couid

bend

and

damage

the

center

pín.)

Screw

the

detector

into

the

connector

at

the

top

of

the

chamber

by

rotating

the

detector

(threads

are

right

handed).

lf

initial

resistance

is

feit,

stop

and

check

for

center

pin

misalignment.

Otherwise,

continue

turnng

the

detector

until

the

5/16-in.

hex-nut

on

the

detector

presses

against

the

top

ot

the

chamber.

On

new

chambers,

use

ot

a

5/16-in.

ignition

wrench

may

be

required

for

the

last

turn.

3.

Remove

the

plastic

cover,

being

careful

not to

touch

the

detector

face

and

thereby

contaminate

it.

3.2.

CONNECTION

TO

POWER

lhe

SOLOIST

Alpha

Spectrometer

is

designed

for

operation

in

a

N1M-standard

bin/power

suppiy

such

as

the

EG&G

ORTEC

Modei

4007/4002

Series.

lhe

power

supply

furnishes operating

power

requrements

at

±12

V

and

±24

V.

These

NIM

bins

have

test

jacks

on

the power

suppiy

control

panei

to

monitor

the

dc

voltage

levei.

Check

that

the proper

voftage

is

avali

abie

at

these

test

jacks

after

ali

modules

have

been

installed

in

the

bin.

3.3.

VACUUM

CONNECTON

Apply

a

clean,

dry,

oil-free

vacuum

from

a

roughing

pump

or

vacuum

manifold

to

the

SOLOIST

Alpha

Spectrometer

through

the

Swageiok

connector

on

the

rear

panei.

This

connector

accepts

1/4-in. CD

tubing

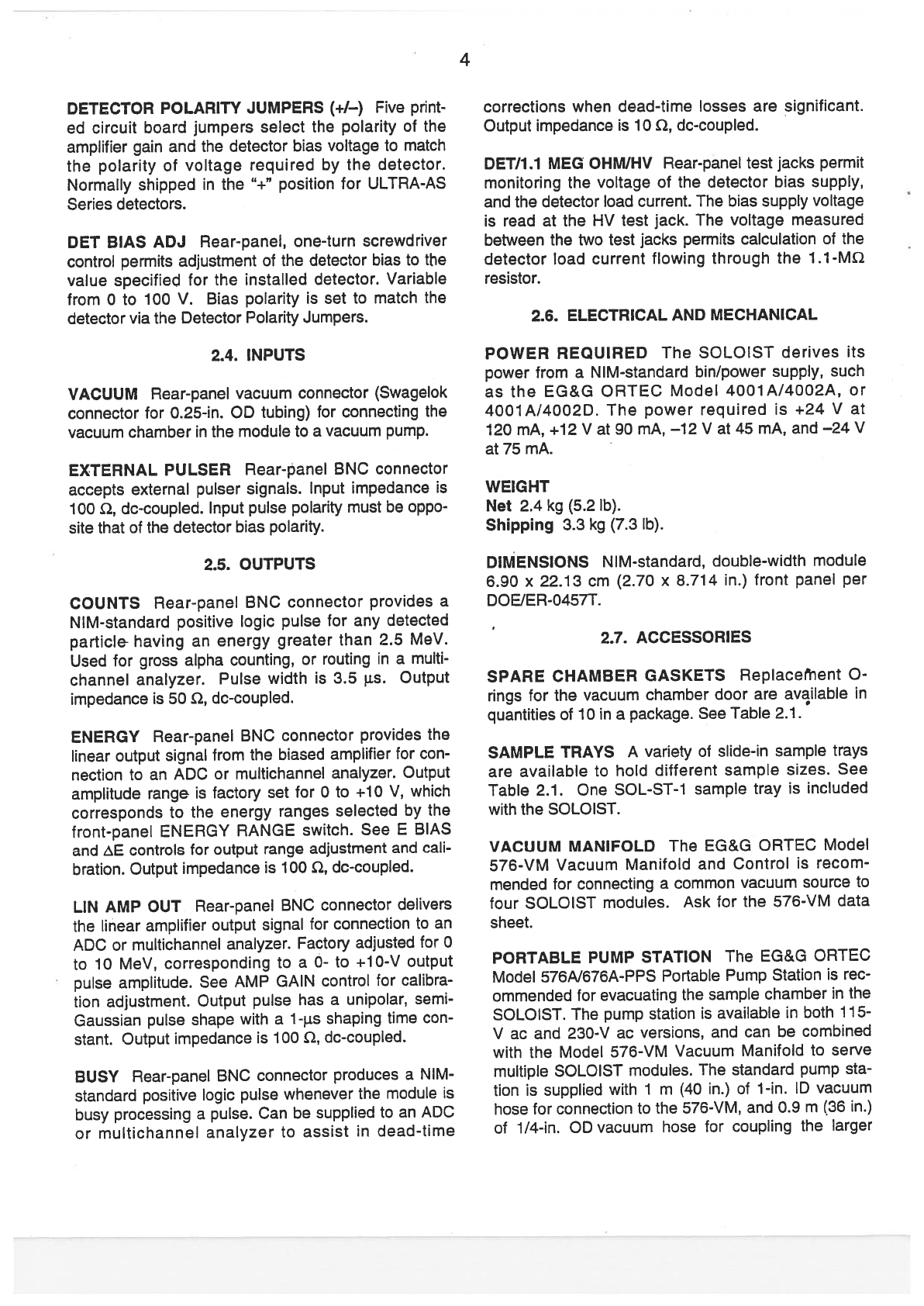

fb)

Vacuum

Connection

for

the

SOLOIST

Using

a

SmaII,

Direct-Driven

Pump

and

ISO KF

Fittings.

676A

II4.n.

Copp.

o,

PoIyrhy.n.

Toblng

Swg.kR.dflg

SiBA

/2.io

Copper

T.bing

Rodiolo,

50••

CIdn,p

‘Bdnd

C.,,,p

1/4

o

FIebIe

Tbnq

ISO

SF114,,

Tob

Addpte,

-

ISO

SF

CIan,p

4

Hn.y

W.H

VICIam

Halo

l/2.,n.

lO

FIeable

U,,Il

HO,,,

011

SacI

r.amng

Trap

CCAUP

DErAS.

Mali,,5

Flange

Aing

(a)

vacuum

Connection

for

the

SOLOIST

Using

a

SmaII,

Bet-Driven

Pump.

01,001

Drive

Pump

Fig.

3.2.(a)

and

(b).

Suggested

Vacuum

Connections

for

the

SOLOIST

Spectrometer.

8

and

is

accessible

when the

module

has

been

instailed

in

the

NIM

bin

[(Fig.

3.2

(a)

and

(b)J.

For

a

single

SOLOIST Alpha

Spectrometer, the

pump

should

have

a

displacement

of

about

2

CFM

(57

liter/min).

if

sev

eral SOLOIST

Alpha

Spectrometer

modules

are

con

nected

togethet

via

a

manifold,

the

pump

should

have

a

displacement

of

about

4

CFM

(113

liter/min).

For

larger

systems

(more

than

four

modules),

a

pump

with

a

displacement

of

6.7

CFM

(190

titers/min)

should

be

used.

An

operating

pressure

of

<50

millitorr

should be

adequate

for

most

applications.

Set

the

front-panel

PUMP/HOLD/VENT

contrai

at

VENT

to

isolate the

vacuum

source

from

the

chamber

and

to

vent

the chamber

to

atmospheric

pressure.

With

the

chamber

door

closed,

the

contrai

can

be

set

at

PUMP

to

connect

the

chamber

to

the

vacuum

source.

Do

not

set

the

control

at

PUMP

unless

the

door

is

closed,

ar

the

vacuum

source

will

be

connect

ed

directiy

to

atmospheric

pressure

through

the

open

chamber.

The

control

can

be

placed

in

the

HOLD

position

to

solate

the

chamber

from

the

manifoid

without

venting

the sample.

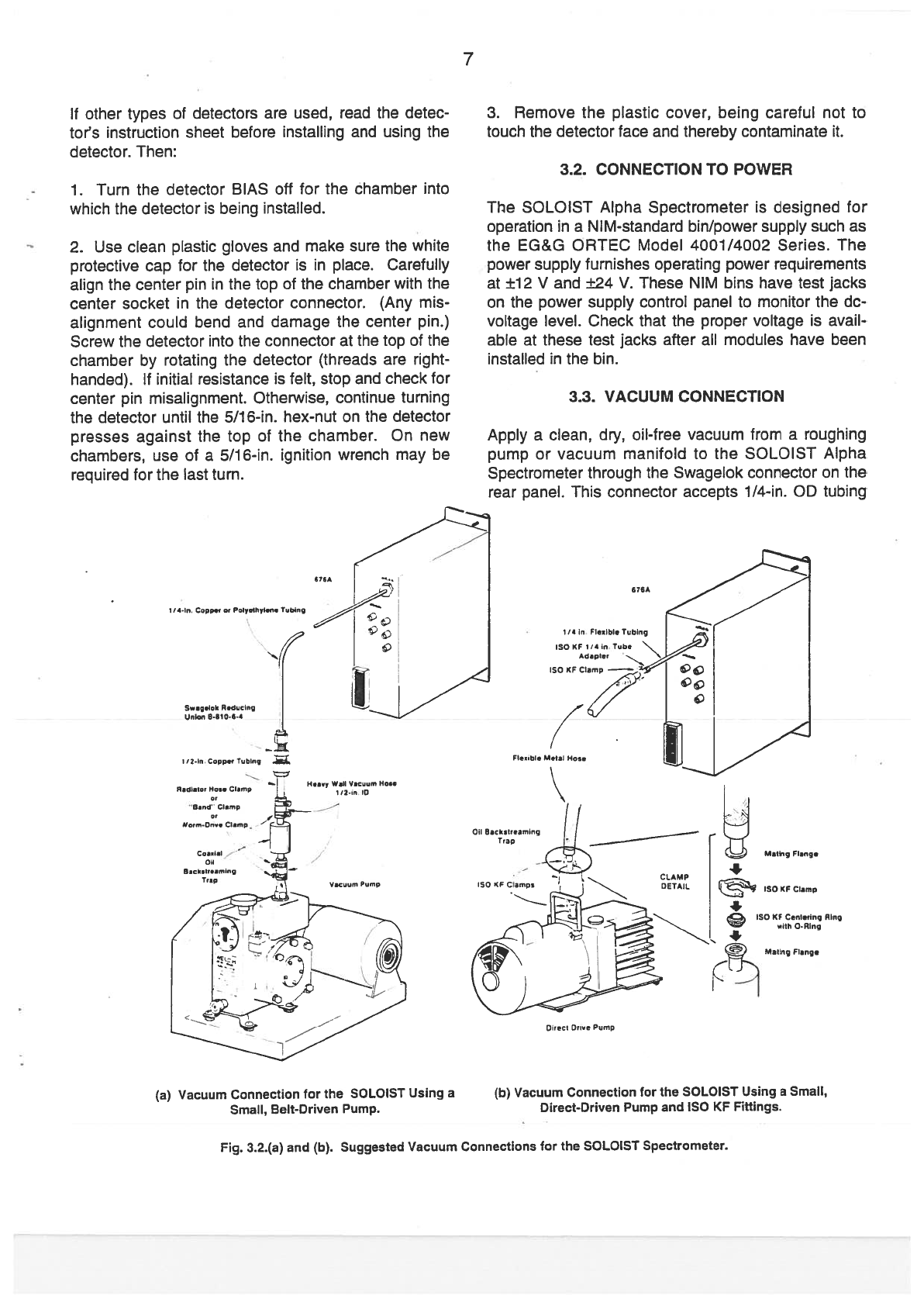

3.4.

SIGNAL

CONNECTIONS

Figure 3.3

shows

the

typical

signal

connections

between

the

SOLOIST,

the

associated

multichannel

analyzer, and

the

optional

counter

and

timer.

lo

gain

use

of

the

biased

amplifler

in

the

SOLOIST,

the

rear

panei

ENERGY

output should

be

connected

to

the

lin

ear

input

on

the

multichannet

anaiyzer.

lf

the bias

amplitier

is

not

desired, the

LIN

AMP

OUT

can

be

connected

to

the

muitichannel

anaiyzer

linear

input.

The

BUSY

signai

is

supplied

to

the

multichannel

ana

Iyzer

to

assist

in

proper

dead-time

corrections.

When

an

external

BNC

cable

longer

than

3

meters

is

used

for input

or

output

connection,

the characteristic

impedance

of

the

cable

shouid

match

the

impedance

of

the

input

or

output

used.

The

EXTERNAL

PULSER

input

and

the

ENERGY

and

LIN

AMP

out

puts should

use

93-2

RG-62A/U

cable,

and

the

COUNTS

and

BUSY

outputs

should

be

connected

using

50-i2

RG-58NU cabie.

For

cabie

lengths

>3

m,

the

coaxial

cable

should

be

terminated

in

its

charac

teristic

impedance

at

the

receiving

end,

Use

a

BNC

Tee

connector

and

terminating

resistor,

if

necessary.

3.5.

ENERGY

OUTPUT FULL-SCALE

ADJUSTMENT

fOther

than

10

V)

The

full-scale

output

from

the

ENERGY

output

is

nor

mally

set

for

10

V,

which

matches

the

input

range

ot

many

multichannel

analyzers

(MCAs).

The

second

most

common

input

range

for MCAs

is

8

V.

lhe

pro

cedure

for

a

8-V

fuli

scale

is

as

foliows:

1.

Set

the

OFF/BIAS/PULSER

switch

to

PULSER.

Set

the

ENERGY

RANGE

switch

to

4-6

MeV

or

the

range

to

be

used.

2.

Observe

the

ENERGY

output

on

an

oscilioscope,

trigger

on

BUSY,

and then

adjust the

PULSER

contrai

for

a

10-V

output pulse.

3.

Adjust

the

front-panel

E

control

for

8-V

output.

Turn

off

the

PULSER

and continue

with

operation

ot

the

SOLOIST Alpha

Spectrometer.

3.6.

LINEAR

AMP

OUTPUT

FULL-SCALE

ADJUSTMENT

(Other

than

10

V)

lhe

full-scale

output

from

the

LIN

AMP

OUT

is

nor

mally

set

for 10

V,

which

matches

the

input

range

of

many

multichannel

anaiyzers

(MCAs).

The

second

most

common

input

range

for

MCAs

is

8

V.

The

pra

cedure

for

8-V

fuil

scale

is

as

foliows:

1.

Set

the

OFF/B1AS/PULSER

switch

to

PULSER.

Set

the

PULSER

contrai

to

10

MeV

for

the

range

to

be

used

within

5

MeV

to

10

MeV).

2.

Observe

the

LIN

AMP

OUT

on

an

oscilioscope,

trigger

on BUSY,

and

then

adjust the

PULSER contrai

for

a

10-V

output

pulse.

3.

Adjust

the

front-panei

AMP

GAIN

contrai

for

8-V

output.

Turn

off

the

PULSER

and continue

with

oper

ation

ot

the

SOLO

IST

Alpha

Spectrometer.

Energy

-1

(Optional)

TER

4111

Fig.

3.3.

Signal

Connections.

9

4.

OPERATION

The

nformation

in

Section

3

includes

ali

of

the

prelim

inary

selections

that

are

to

be

made

for

the

SOLO

IST

Alpha

Spectrometer.

Operation,

then,

consists

of

inserting

a

sample

that

is

to

be

exarnined

into

the

chamber

and

proceeding

with

data

accumulation.

Basic

control

settings

that

should

be

used

before

ínserting

a

sampie

and

between

operating

cycles

are:

OFF/BIAS/PULSER

VACUUM

Control

ENERGY

RANGE

PULSER

Dial

DET

BIAS

ADJ

Then

use

the

following

steps:

1.

Piace the

standard

sampie

in

the chamber.

2.

Evacuate

the

chamber.

lf

this

module

has

a

com

mon

vacuurn

with

other

SOLOIST Alpha

Spec

trometers,

put

the

other modules

on

HOLD

while

this

module

is

pumped

down.

3.

Turn

on

the

BIAS,

and

count

the

standard.

4.

Perform

the energy

and

efficiency

calibration.

5.

Repeat

steps

1-3

with

a

prepared

sample.

Note:.

for

quantitatively

meaningful

results,

the

sample

must

be

placed

at

the

sarne

distance

from

the

detector

as

the

calibration

standard.

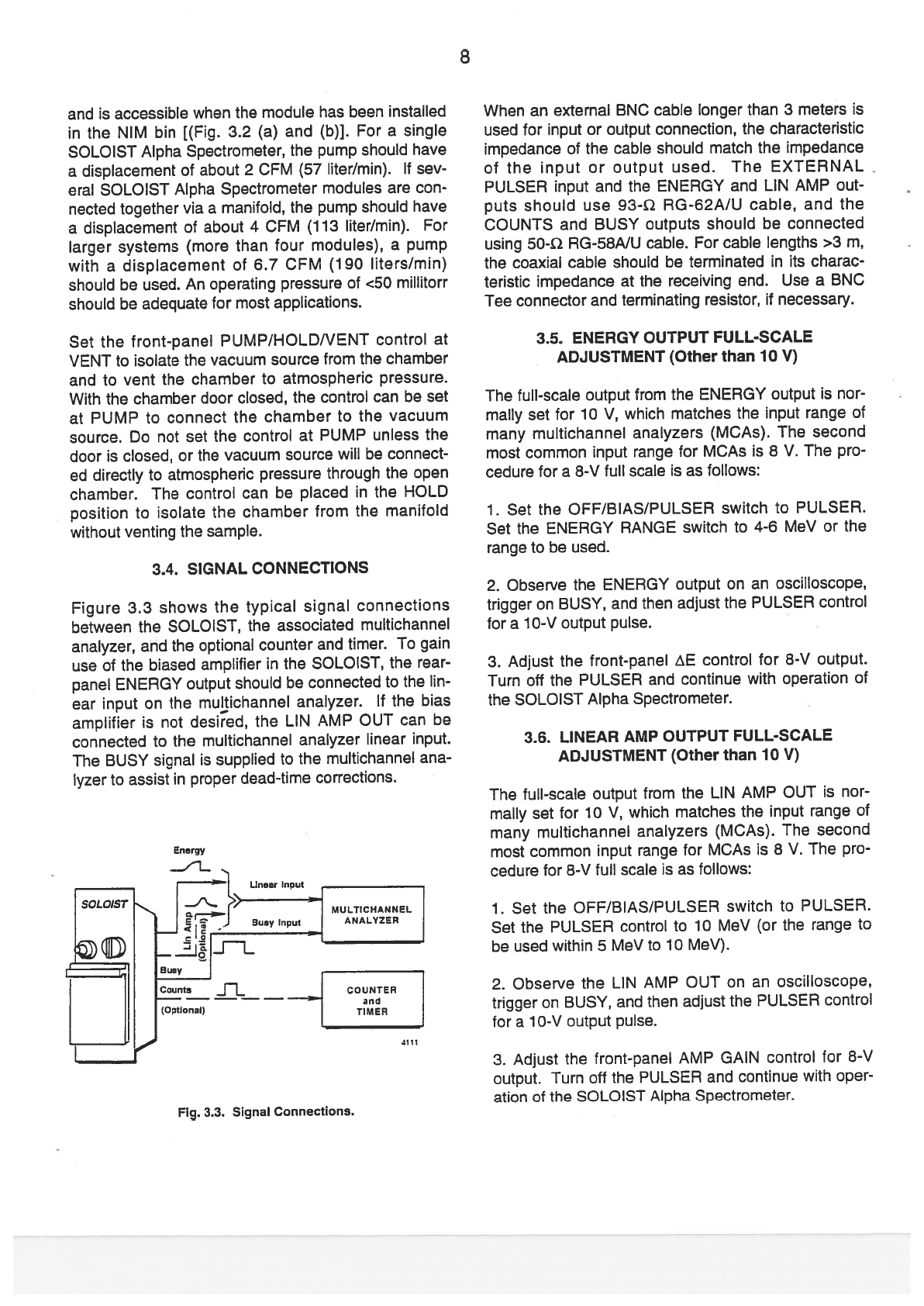

4.1.

OPERATING

PUMP/HOLDNENT

VALVE

lhe

PUMP!HOLDNENI

vaive

is

a

3-position vaive.

The

PUMP

position

connects

the

chamber

to

the

manifold

(see

Fig.

4.1),

the

HOLD

position

isolates

the chamber,

and

the

VENT

position

connects

the

chamber

to

the

atmosphere,

allowing

the

door

to

be

opened.

4.2.

SAMPLE

INSERTION

Turn

the

chamber

valve

to

the

VENT

position

and

open

the

door.

Silde

the

sample

holder

into

the

slot at

the

desired

height.

(Note

that,

for

optimum

resolution,

the

sample-to-detector

spacing

should

be

at

least

equal

to

the

detector

diameter.)

The

sarnple

spacing

is

selectable

from

1

mm

to

41

mm,

in

4-mm

incre

ments.

lhe

sample

trays

shipped

with

the

SOLOIST

are

for

3/4-inch

and

1-inch

sampies.

Additional

sets

of

sample

trays

of

4

different

sizes

are

available.

See

Section

2.7

for

a

description

of

the

sample

trays.

When

the

sample

is

in

place,

dose

the

door,

and

turn

the

vacuum

valve

to

PUMP.

After

a

minute

or

two,

when

the

vacuum

has

reached

asatisfactory

value

(100

millitorr

or

less), start

the

data

coliection.

lf

other

chambers

connected

to

the

sarne

vacuum

manifold

have

been

placed

on

HOLD

(see

above),

they may

now

be

returned

to

the

PUMP position.

4.3.

RESOLUTION MEASUREMENT

AND

CAUBRATION

lhe

measurement

of

alpha

particle

resolution

should

be

performed

in

a

vacuurn

with

an

ultra-thin,

point

sou

rce

located

at

a

sou

rce-to-detector distance

at

least equal

to

the

detector

diameter.

The

use

of

old

or

inferior

sources

may

cause

apparently

poor

resolution

and

can

also

Iead to

detector

contarnination

due

to

recoil

sputtering.

When

a

source

is

used

in

an

SOLOISI

charnber, either

for

resolution

measure

ment or

systern

calibration,

these

steps

should be

foi

lowed

for

optimum

resuits.

4.3.7.

RESOLUTION MEASUREMENT

1.

Piacing

a

source

in

the

chamber

can

contaminate

the

chamber/detector

and

is

not

recommended

if

the

low

background

specification

of

the

SOLOIST

is

to

be

maintained.

lhe

caiibrated

Test

Pulser

can

be

used

to

test

the

system

electronic

noise

by

rneasuring the

FWHM

spread

of

the

pulser

peak

on

the

MCA

from

the

ENERGY or

LIN

AMP

OUT.

0FF

VENT

Selection

for

Sample

Energy

o

+50

V

for

EG&G

ORTEC

ULTRA-AS

detectors.

fOther

detectors

as

specified

on

detec

tor

data

sheets).

Fig.

4.1.

PUMP/HOLDNENT

Valve.

lo

2.

Evacuate

the

chamber.

3.

Turn

the

BIAS

on.

Wait

for 2

minutes.

4.

Accumulate

a

peak

containing

at

least

1

OOO

counts

in

the

peak

channel.

5.

Determination

of

the

resolution

requires

the

meas

urement

of

the

fuU-width

at

1/2

maximum

(FWHM)

of

the

peak.

Note:

lf

the

source

is

to

be

used,

place

the

source

on

a

sample

tray

and

insert

tinto

the

SOLQIST

cham

ber. Placing

the source

as

far

as

possible

from

the

detector

helps reduce

any

solid-angle-related

and/or

count-rate

problems.

4.3.2.

CALIBRATION

System

calibration

is

essentially

composed

of

two

parts:

1.

Counting

a

known

standard

containing

two

alpha

emitters,

and

using

the

known

energies

to

determine

the

energy

calibration.

For

low-background

applica

tions

the

calibrated

Test

Pulser

can

be

used

to

place

a

peak

near each

end

of

the

selected

Energy

Range

then:

E=A+B*Chn

where

A

is

the

energy

of

the

lowest

channel

in

the

system

in

MeV

and

6

is

the

gain

in

MeV/channel.

E

is

the

energy

of

channel

Chn. This

process

is

carried

out

easily

via

the

MCA

Emulation

software

(see

rele

vant

manual).

For

use

with

other

MCA

systems

see

the pertinent manual.

2.

Performing

an

efficiency

calibration.

The

efficiency

calibration

is

a

determination

ot

the

ratio

between the

number

ot

alpha

particles

of

a

particular

nuclide

and

enetgy

emiffed

by

the

source,

and

the

number

actual

ly

recorded

from

that

source

in

the

corresponding

spectral

peak.

Efficiency

calibration

may

be determined

manuafly,

or

may

be

determined

as

a

part

of

a

quantitative

analy

sis

package

such

as

EG&G

ORTEC’s

ALPHAMArM.

Unlike

gamma-ray detectors, the

efficiency

of

a

solid

state

alpha

detector

is

constant

over

the

energy range

of

interest

to

alpha

spectroscopists.

11

5.

THEORY

OF

OPERATION

The

complete

schematics

for

the

SOLOIST

Alpha

Spectrometer

[Part

No.

761250

(Alpha

Spectrometer)

and 764030

(Linear

Amplifier)]

are

included

at

the

back

of

this

manual.

Figure

5.1 is

a

block

diagram

of

the

electronics.

The

detector

voltage

(OFF/BIAS/PULSER)

switch

on

the

front

panei

turns

power

on

and

off

for

the

variable

100-V

power

suppiy.

The

power

is

on

in

both

the

BIAS

and

PULSER

positions.

The

poiarity

is

set

by

jumper

Ji,

which

is

actuaily

three

separate

jumpers

(see

schematics).

The

indica

ted

poiarity

is

positive,

which

is

appropriate

when

an

EG&G

ORTEC

ULIRA-AS

or

standard detector

is

used.

When

the

detector

voltage

is

positive,

its

out

put

pulses

are

negative.

When

they

pass

through

the

inverting

preamplifier

they

are

positive,

and

this

is

the

polarity

that

is

then

selected

by

the

pair

of

jumpers

J3,

on

the

PWB.

if

a

Ruggedized

surface

barrier

detector

is

used,

ali

five

of

ttese

jumpers

must

be

changed

to

“—“

because

the

Ruggedized

detector

operates

on

a

negative

voltage and

generates

positive output

pulses,

which

are

then

inverted

and

are

negative

pulses

at

the

J3

location

in

the

circuit.

The

100-V

power

supply output

on

the

PWB

can

be

tested

for

both

poiarity

and

amplitude

at

test

point

TP1,

which

is

identif

leU

on

the

PWB.

The

variable

O

to

100

V

bias voltage

can

be

measured

at

the

rear-panel

test

jack

labeled

HV.

The

detector leakage

current

can

be

calculated

from

the

voltage

across

the

1.1-Me

resistor,

between rear-panel

test jacks

DET

and

HV.

A

10-M2

impedance

meter

should be

used.

The

out

put

ot

the

BIAS

supply

is

applied

through

a

high

impedance

(totaling

23

M2)

to

the

dc

connection

between

the

detector

and

the

preamplif

ler.

lhe

output

from

the

charge

sensitive

preamplif

ler

can

be

checked

at

TP2.

lhe

nominal

conversion

gain

is

45

mV/MeV,

lhe

preamplitier

gain

from

the

EXTER

NAL

PULSER

input

is

nominally

“—1”

at

lP2.

lhe

front-panel

PULSER

switch

(OFF/BIAS/PULSER)

turns

power

on

and

off

for

the

test

pulser.

lhe

test

pulser

can

be

set

using

the

10-turn,

front-panel

poten

DETECTOR

VOLTAQE

Fig.

5.1.

Detailed

Block

Dagram

of

the

SOLOIST

Alpha

Spectrometer.

12

tiometer

to

furnish

the

equivaient pulse

amplitude

for

0

to

10

MeV

at

the

input

to

the

preamplifier.

A

screw

driver

calibration

is

included

on

the

PWB

for

factory

adjustment

of

the

test

pulser

circuit

and

should

not

be

changed

by

the

customer.

When

the

front-panel

tog

gle

switch

is

set

at

BIAS,

the

test

pulser

is

turned

off

and

does

not

appear

in

the

output

spectrum.

Pulses

from

the

detector and/or

the

test

pulser are

inverted

by

the

preamplifier

and

are

furnished

as

the

input

to

the

amplifier

that inciudes

the

first

integration

and

differentiation

shaping

circuits.

The

amplifier

can

be

calibrated

by

a

factory-adjusted

trim

potentiometer

on

the

PWB,

The

output

is

a

shaped

negative

pulse

that

can

be

observed

at

test

point

1P3.

The

pulse

at

lP3

is

furnished

into

a

fixed-level

dis

criminator

U3

and

through

a

diode

dc-restorer

and

integration

network.

lf

the amplitude

represents

—2.5-MeV

or

more,

the

discriminator

fites

and

gener

ates

a

positive-shaped

pulse that

is

used

to

enable

the

stretcher.

This

pulse

is

also

provided

as

the

COUNTS

output

signal.

lhe

pulse

from

the

second

integration

shaping

circuit

is

futnished

to

the

stretch

er.

lf

the

stretcher

is

enabled,

the

peak

amplitude

is

stretched

to

improve

the

measurement

accuracy

of

the

MCA,

which

uses

the

ENERGY

output

for

meas

urement.

lt

the

sttetcher

is

not

enabled

(because

the

pulse

represents

<2.5

MeV),

the

output

is

passed

to

the

biased

amplifier without

being

stretched.

lhe

out

put

of

the

sttetcher

is

a

negative

pulse

and

can be

monitoted

at

test

point

lP4

on

the

PWB.

lhe

biased

amplifier

accepts

the

stretcher

output

and

the

bias

levei

selected

by

the front-panel

ENERGY

RANGE

switch

(low

end

of

range). The bias

levei,

or

lower

levei,

accepted

into

the

biased

amplifier

can

be

set

at

3,

4,

5,

or

6

MeV by

the

ENERGY

RANGE

switch

and

can

be

adjusted

by

±10%

by

the

ftont

panei

screwdtiver

control,

E

BIAS.

lhe

function

of

the

biased

amplifier

is

to

subtract

the

bias

levei

from

the

input

pulse amplitude

and

to

amplify

the

excess

amplitude

by

a

factor

of

10

on

the

3-5,

4-6,

5-7,

and

6-8

MeV

ranges,

a

factor

of

6.7

on

the

4-7

MeV

range,

or

a

factor

of

4

on

the

3-8

MeV

range.

lhe

out

put

of

the

biased

amplif

ler

is

a

positive

pulse

with

an

amplitude

in

the

range

of

O

to

10

V

that

is

proportionai

to

the

amount

by

which

the

detected

input

energy

exceeds

the

selected

bias

levei,

lhe

full-scale

output

of

10

V

can

be

adjusted

down

to

7.75

V

using

the

front-panei

screwdriver

control,

E.

51.

SOLOIST

ALPHA

SPECTROMETER

LINEAR

AMPUFIER

SCHEMATIC

lhe

pulse

at

lP3

is

also furnished

to

a

positive gain

of 10

ampiifier

with

a

diode-iimited,

continuous

dc

restoration

ioop

(see

Linear

Amplifier

schematic).

lhe

second

integration

for

the

tear-panei

LIN

AMP

QUI

is

implemented

in

the

amplifier

input

network.

lhe

LIN

AMP

OUI

is

a

positive 1-.ts

shaped

pulse.

The

output

amplitude

is

adjustabie

ovet

a5-MeV

to

10-MeV

range

by

the

front-panel

screwdriver

controi,

AMP

GAIN.

lhe

output

is

factory

set

to

10

MeV

at

10V.

The

BUSY

output

pulse

is

generated

by

a

discrimina

tor

that

provides

a

+5

V

levei

whenever

the

LIN

AMP

QUI

exceeds

the

discriminator’s

70-mV

reference

voitage.

13

6.

MAINTENANCE

AND

SERVICE

6.1.

DECONTAMINATION

The

normal

background

count

above

3

MeV

for

each

channel

in

the

SOLOIST

should

be <24

counts

per

day

for

the

300- and

450-mm2

ULTRA-AS

Series

detectors.

lf

an

increase

of

background

is

noted,

this

may

be

caused

by

contamination

of

the

chamber

and/or

the

detector

by

residual

deposits

of

alpha-emit

ting

materiais.

Decontamination

of

the

chamber

and

of

the

detector

fif

ULTRATM

or

Ruggedized)

is

indicat

ed.

Non-Ruggedized

surface

barrier

detectors

cannot

be

subjected

to

cleaning

procedures;

con

sult

the

instruction

manual for

the

detector

to

determine

any

measures

that

may

be

helpfuL

6.1.7.

CHAMBER

DECONTAMINATION

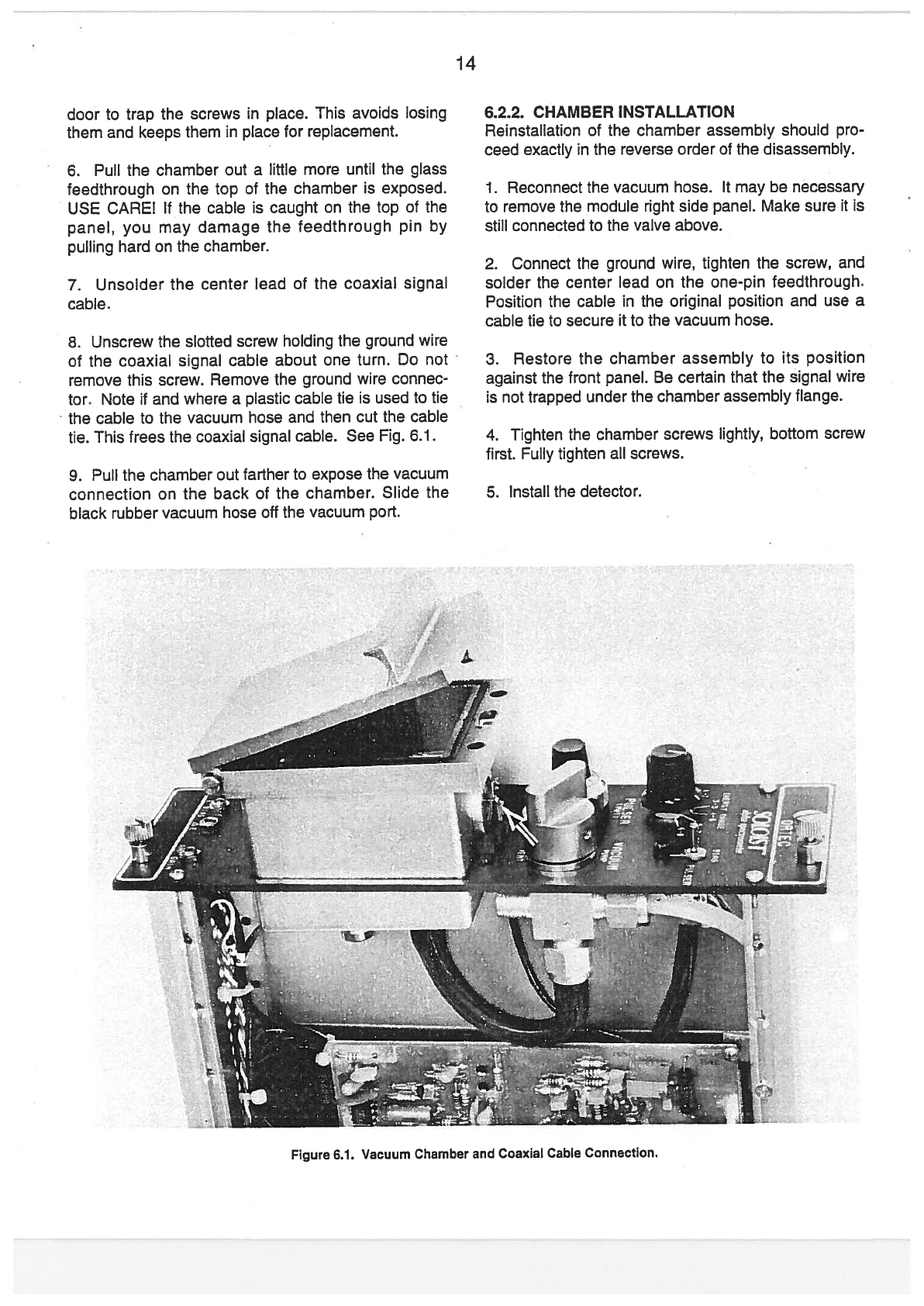

Use the

following

steps

to

decontaminate

a

SQLOIST

chamber.

1.