installation &

operating instructions

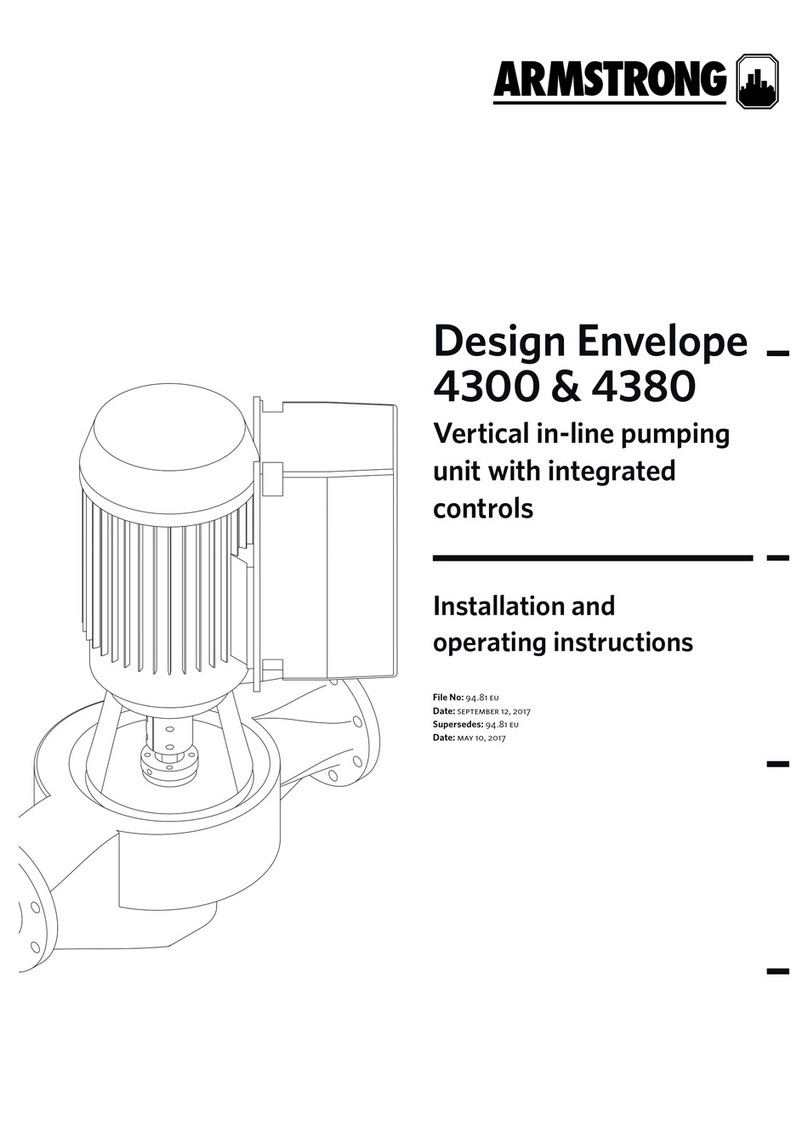

Design Envelope 4302 ivs and 4382 ivs vertical

in-line pumping unit with integrated controls

5

installed in such a manner that the pump is not used as a

pipe support.

• Do not rigidly connect the pump to a permanent base (see

fig. 2.7 on page 10) Note: if the pump must be connected

to a permanent base, the pump must be isolated from the

piping by flexible connectors and the base isolated from the

building structure on an inertia base.

• Do not install the unit with the shaft horizontal.

• Do not support the installed unit by the motor eye bolts or

by supports to any other part of the pump other than

stated above.

important

All Series 4302 ivs pumps contain a tapped hole in the motor

bracket above the discharge flange for draining the well. Pipe

this drain hole to a floor drain to avoid overflow of the cavity

caused by collecting chilled water condensate or from

seal failure.

2.1.4 pump piping – general

Never connect a pump to piping, always start piping

from pump.

Use as few bends as possible and preferably long

radius elbows.

Do not use flexible connectors on the suction or discharge.

Make sure piping exerts no strain on pump as this would

distort the casing and cause pump misalignment.

Suction and discharge pipes may be increased at pump

nozzle to suit pump capacity and particular conditions of

installation. Use eccentric reducers on suction connection.

Lay out the suction line with a continual rise towards the

pump without high points, thus eliminating possibility of air

pockets that may prevent the pump from operating.

A strainer of three or four times the area of the suction pipe,

installed in the suction line, will prevent the entrance of

foreign materials into the pump. V" (3mm) diameter perfora-

tions in the strainer are typical.

Test suction line for air leaks before starting; this becomes

essential with long suction line or static lift.

Install, at pump suction, a straight pipe of a length equivalent

to 4or 6 times its diameter; this becomes essential when

handling liquids above 120°f (49°c). Armstrong suction

guides may be used in place of the straight pipe run and in

line strainer.

Install isolation valve in both suction and discharge lines

on flooded suction application; this valve is used mainly to

isolate the pump for inspection or repair.

Install a non-slam check valve in discharge line between

pump and isolation valve to protect pump from excessive

back pressure and to prevent water running back through the

pump in case of driver failure. Armstrong Flo-Trex valve

may be used in place of check valve and isolation valve on

pump discharge.

caution

Discharge valve only must be used to reduce the

pump flow, not the suction valve.

Care must be taken in the suction line layout and

installation, as it is usually the major source of

concern in centrifugal pump applications.

important

Do not run the pump for any length of time under very low

flow conditions or with the discharge valve closed. To do so

could cause the water in the casing to reach super heated

steam conditions and will cause premature failure and could

cause serious and dramatic damage to the pump and

surrounding area.

2.1.5 alignment

The pumping unit is accurately aligned at the factory prior

to being shipped.

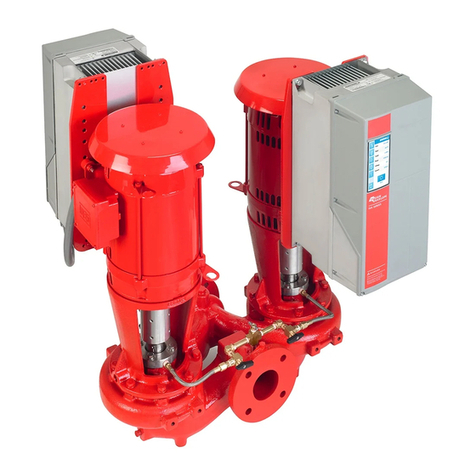

Alignment on the 4302 dualArm may be verified by

assuring an equal gap between coupling halves on both

sides of the coupling.

operation

2.1.6 starting pump

The pump must be fully primed on start up. Fill the pump

casing with liquid and rotate the shaft by hand to remove any

air trapped in the impeller. Air trapped in the casing must be

removed by the manual air vent in the seal flush line.

Ensure entrained air is removed from series 4302 ivs and

4382 ivs pumps, prior to starting, through the air vent on

the seal flush line. Open vent until clear of air.