installation &

operating instructions

Astro 2

circulator models

4

warning

•Prior to installation, read these installation and

operating instructions. Installation and

operation must comply with local regulations and

accepted codes of good practice.

• The use of this product requires experience with and knowl-

edge of the product. Only licensed or trained installers

should install this product.

• For supply Connection, use wires acceptable for at least

90°c (194°f).

• Risk of shock: this pump has not been tested for use in

swimming pools or marine areas.

• To reduce risk of electric shock: Unplug before servicing,

see instructions for proper installation, connect to a prop-

erly grounded, grounding type receptacle only.

• For indoor use only.

• Use copper conductors only.

• Do not install with motor above or below pump body.

• Do no submerge.

• Do not run pump dry.

These installation and operating instructions are applicable to the

following Astro 2 models.

1.0 introduction

You are about to install a pump from the finest multi-speed wet

rotor circulator line on the market today. The Armstrong Astro

2circulators are designed for closed hydronic or potable water

systems. Their intended use is for circulating water or glycol

solutions. For pumping domestic water use non-ferrous lead

free bronze or stainless steel body pump construction.

The Astro 2 operates extremely quietly and is lubricated by the

system liquid being pumped by the circulator.

These circulators except Astro 286 are designed to work at

temperatures and pressures up to 230°f (110°c) and 150 psi.

Astro 286 is designed to work at temperature and pressure

upto 150°f (65°c) and 150psi. For fluid temperature upto 185°f

(85°c), operating current must not exceed 1.35a. For lead free

bronze and stainless steel pumps used in potable water sys-

tems, it is recommended that the operating temperature of the

fluid be kept as low as possible (i.e. below 150°f/65°c) to avoid

precipitation of calcium.

When unpacking the circulator, inspect for any damage that

may have occurred during transit. Check for loose, missing or

damaged parts.

2.0 installing

We recommend that any soldering be done before the pump

is actually installed. This will eliminate the possibility of solder

dropping into the pump body.

Thoroughly flush the system out before installing the circulator.

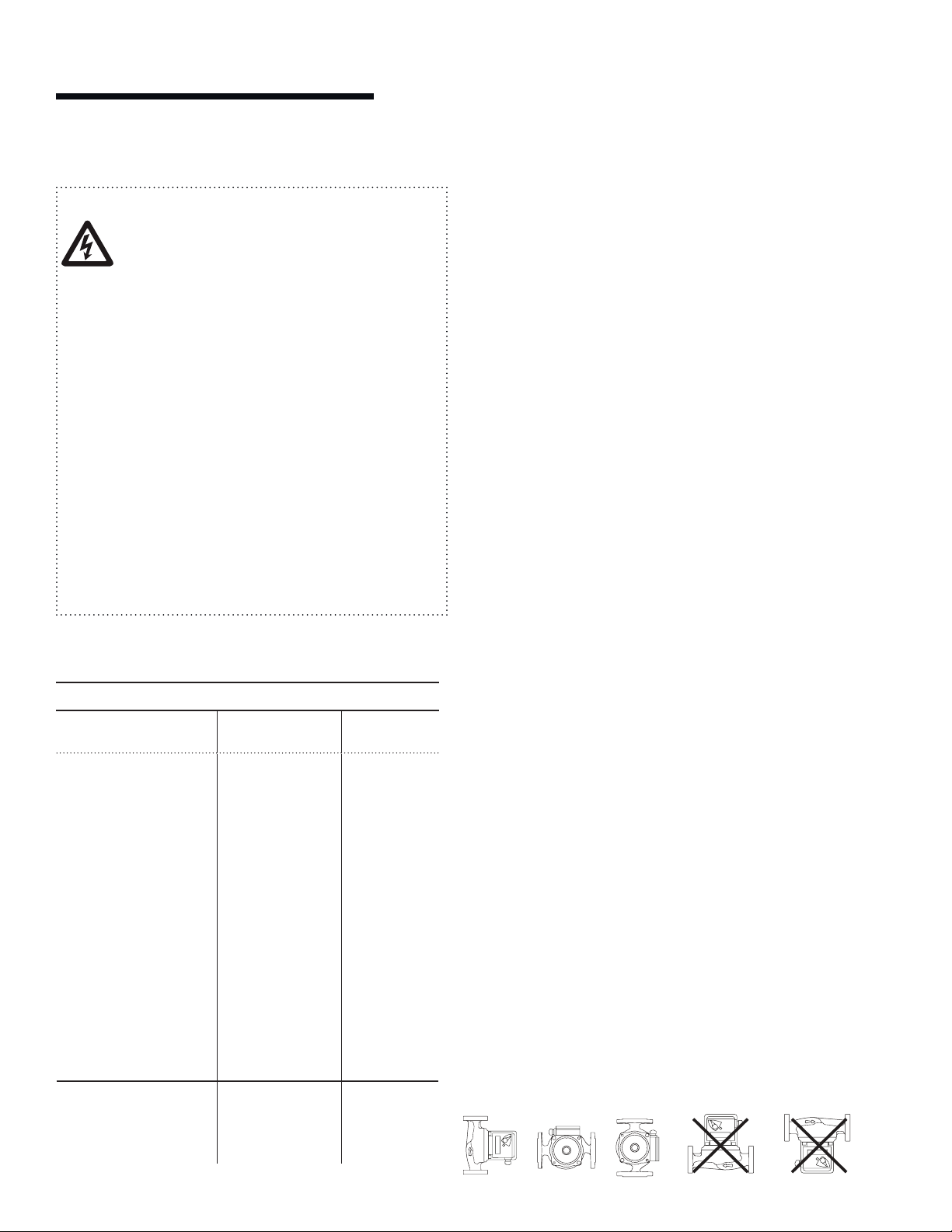

Before Installing, check that the flow direction of the water

through the pump body matches the arrow on the circulator

body. The circulator is supplied for up discharge installation.

Install the circulator in either the outlet or inlet line to the boiler

or hot water heater. It is important to install these circulators

with the split between the circulator body and the motor in a

vertical position. This ensures ecient operation.

See installation examples.

astro 2 models

model electrical

input

rating

astro 210ci

115v, 60hz

Single phase

200w, 1.72a

astro 210ss 200w, 1.72a

astro 220ssu 33w, 0.29a

astro 225ssu 83w, 0.69a

astro 225bs ½" swt 75w, 0.64a

astro 225bs O" swt 75w, 0.64a

astro 230ss 97w, 0.81a

astro 230ci 97w, 0.81a

astro 230ci-r 97w, 0.81a

astro 250ss 117w, 0.98a

astro 250ci 117w, 0.98a

astro 250ci-r 117w, 0.98a

astro 280ci 218w, 1.9a

astro 280ss 218w, 1.9a

astro 290ci 218w, 1.9a

astro 290ss 218w, 1.9a

astro 280ci 230v

230v, 60hz

Single phase

210w, 0.9a

astro 280ss 230v 210w, 0.9a

astro 286ci 370w, 1.6a

astro 286ss 370w, 1.6a

incorrect installationscorrect installations