2

CE CONFORMITIES

For declaration of conformities contact Armstrong.

1.0 UNCRATING

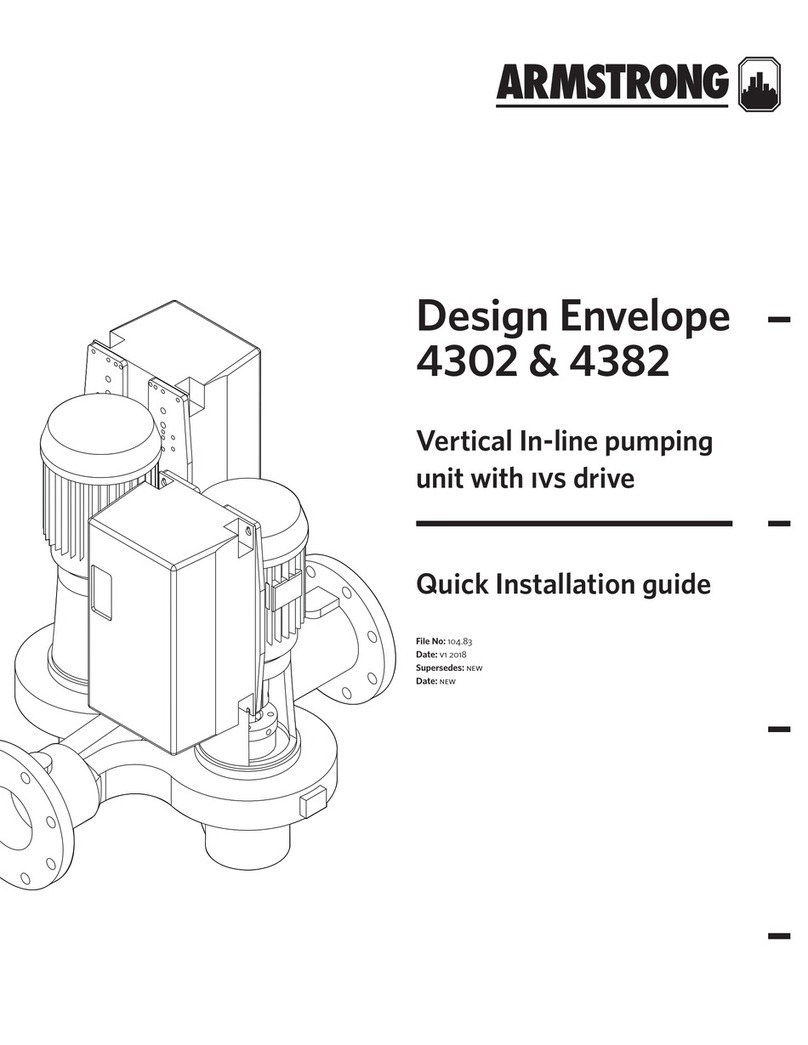

Armstrong dualARM Design Envelope 4302 IVS in-line

pumps are thoroughly inspected before shipment to

assure they meet with your order requirements. After

removing the pump from the crate, make sure the

equipment is in good order and that all components are

received as called for on the packing list. Any shortages

or damage should be reported immediately. Use extreme

care in handling the unit, placing slings carefully so that

stress will not be imposed on the integrated controls,

pump or motor. NEVER PLACE CABLE SLINGS

AROUND THE PUMP SHAFT OR INTEGRATED CON-

TROLS. The eye bolts or lifting lugs on the motor are

intended for lifting only the motor and not the complete

unit.

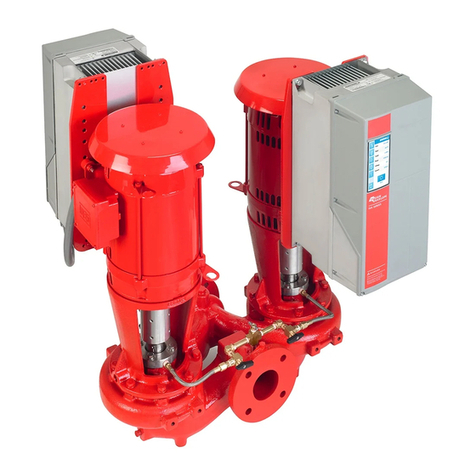

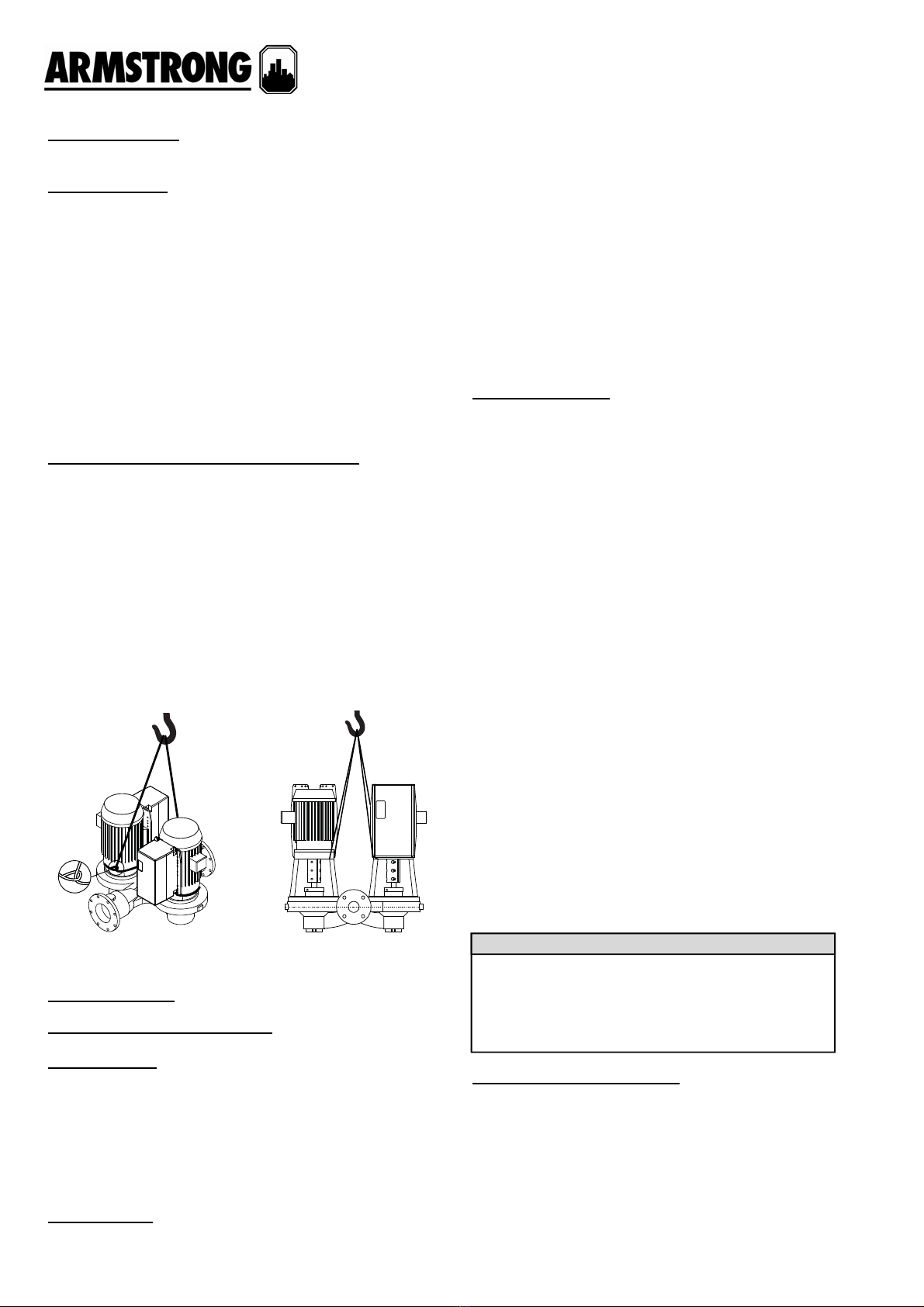

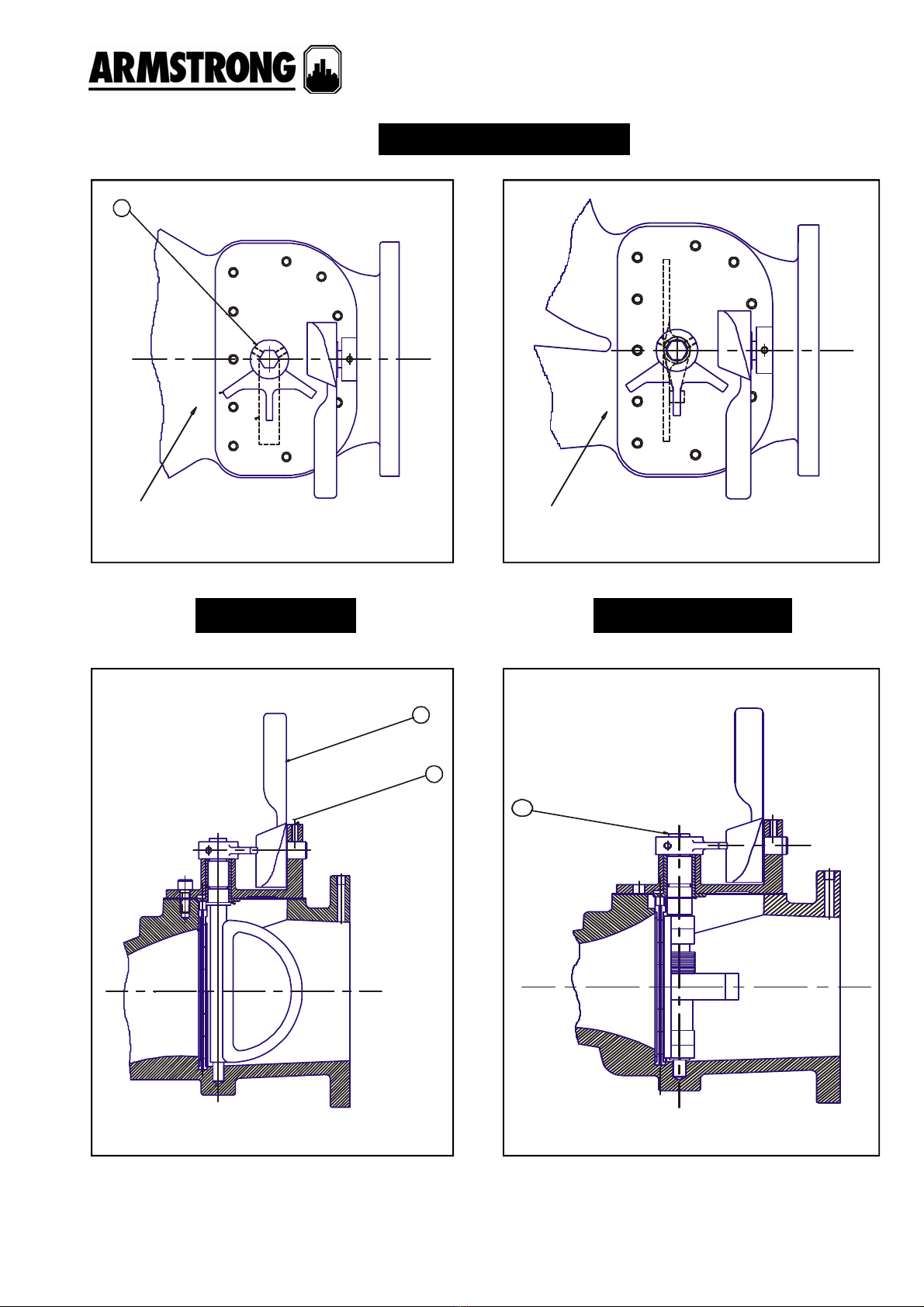

1.1 HANDLING 4302 IVS & 4382 IVS UNITS

Series 4302 IVS & 4382 IVS dualARM units are handled

in a similar manner to the normal dualARM units. Extra

care is required to ensure the integrated controls do not

get damaged during lifting and installation. Remove the

coupling guards and insert lifting straps through each

pump/motor pedestal on the inner side of each coupling.

As the lifting device is engaged (Using a spacer bar if

necessary) and the straps tighten ensure no part of the

strapping is touching any part of the control or motor fan

cover. Lift the pumping unit carefully from the pallet in

this manner and allow the unit to stand upright on a flat

surface and re-position the straps, if necessary, to ensure

safe and damage free transportation into the pipe installa-

tion.

2.0 INSTALLATION

2.1 MECHANICAL INSTALLATION

2.1.1 LOCATION

Locate the unit as close as practical to the liquid

being pumped, with a short, direct suction pipe.

Ensure adequate space is left above and around the

unit for operation, maintenance, service and

inspection of parts.

Electric motor driven pumps should not be located in

damp or dusty location without special protection.

2.1.2 STORAGE

Pumps not immediately placed into service, or

removed from service and stored, must be properly

prepared to prevent rusting

Rotate the shaft periodically to keep rotating element

free.

For long term storage, the pump must be placed in a

vertical position in a dry environment.

Internal rusting can be prevented by removing the

plugs at the top and bottom of the casing and drain

or air blow out all water to prevent rust build up or

the possibility of freezing. Be sure to reinstall the

plugs when the unit is made operational.

Rustproofing or packing the casing with moisture

absorbing material and covering the flanges is

acceptable. When returning to service be sure to

remove the drying agent from the pump.

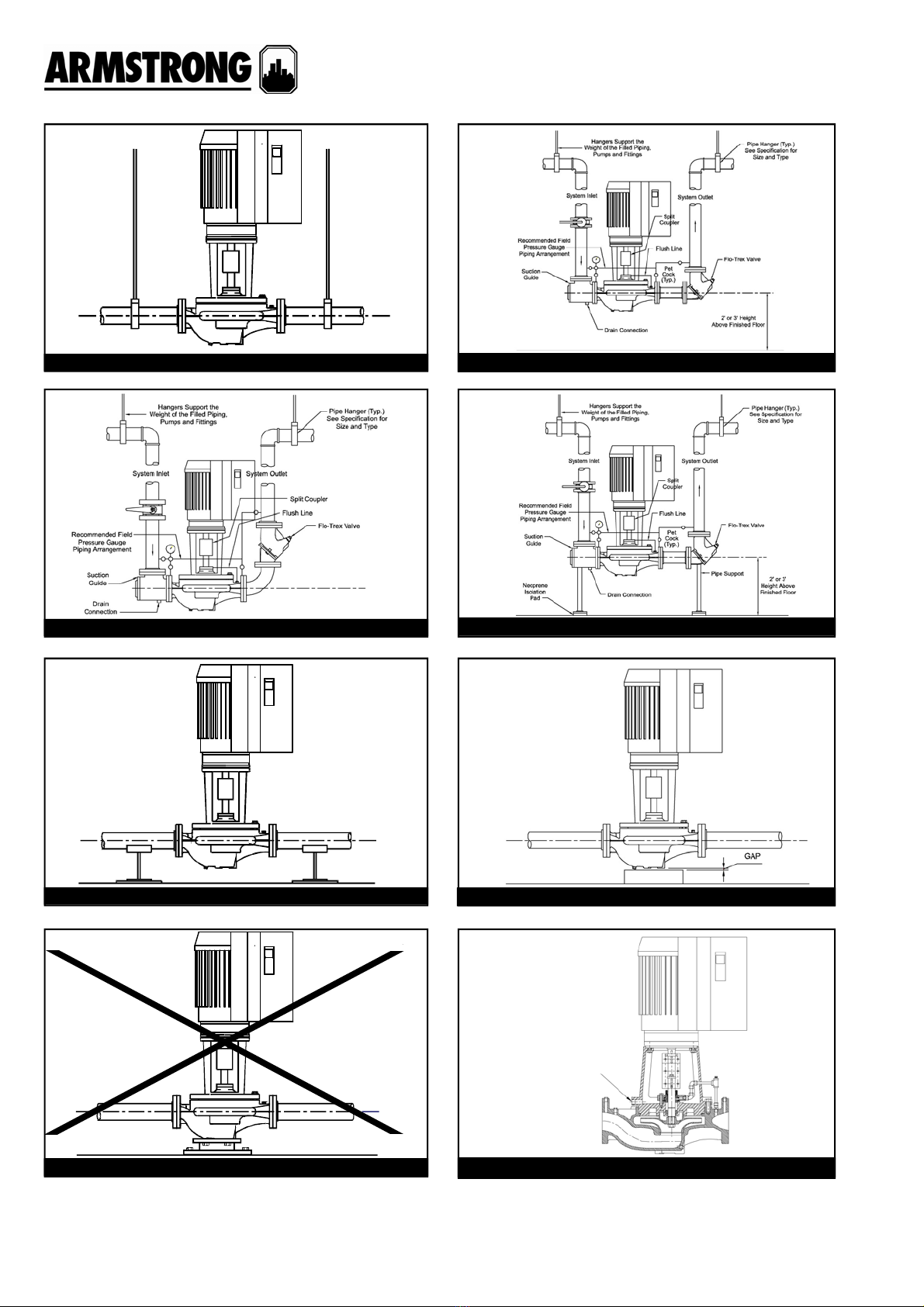

2.1.3 INSTALLATION

The most important consideration when installing a

Series 4302 IVS pumping unit is to make sure the

pump is free to ‘float’ with expansion and contraction

of the piping. Recommended arrangements are:

Supported from the ceiling by pipe hangers (See Fig.

2.1 on page 8)

Pipe supported at the ceiling, with the dualARM

free-standing and mounted with an Armstrong Suc-

tion Guide & Flo-Trex valve. (See Figs. 2.2 & 2.3 on

page 8)

Piping supported at ceiling with additional floor

mounted supports under Armstrong Suction Guide

and Flo-Trex Valve (See Fig. 2.4 on page 8)

Floor mounted saddle supports (See Fig. 2.5 on

page 8)

Where required, additional floor support may be

obtained as shown in Fig. 2.5. Note that the pump

must not be rigidly attached either to the plate or to

the block. Leave a 1/8” (3mm) gap between pump

and base. The piping must be installed in such a

manner that the pump is not used as a pipe support.

DO NOT rigidly connect the pump to a permanent

base (See Fig. 2.7 on page 8) Note: if the pump

must be connected to a permanent base, the pump

must be isolated from the piping by flexible

connectors and the base isolated from the building

structure on an inertia base.

DO NOT install the unit with the shaft horizontal.

DO NOT support the installed unit by the motor eye

bolts or by supports to any other part of the pump other

than stated above.

2.1.4 PUMP PIPING - GENERAL

Never connect a pump to piping, always start piping from

pump.

Use as few bends as possible and preferably long radius

elbows.

Do not use flexible connectors on the suction or

discharge.

Make sure piping exerts no strain on pump as this

would distort the casing and cause pump

misalignment.

4382 IVS 4302 IVS

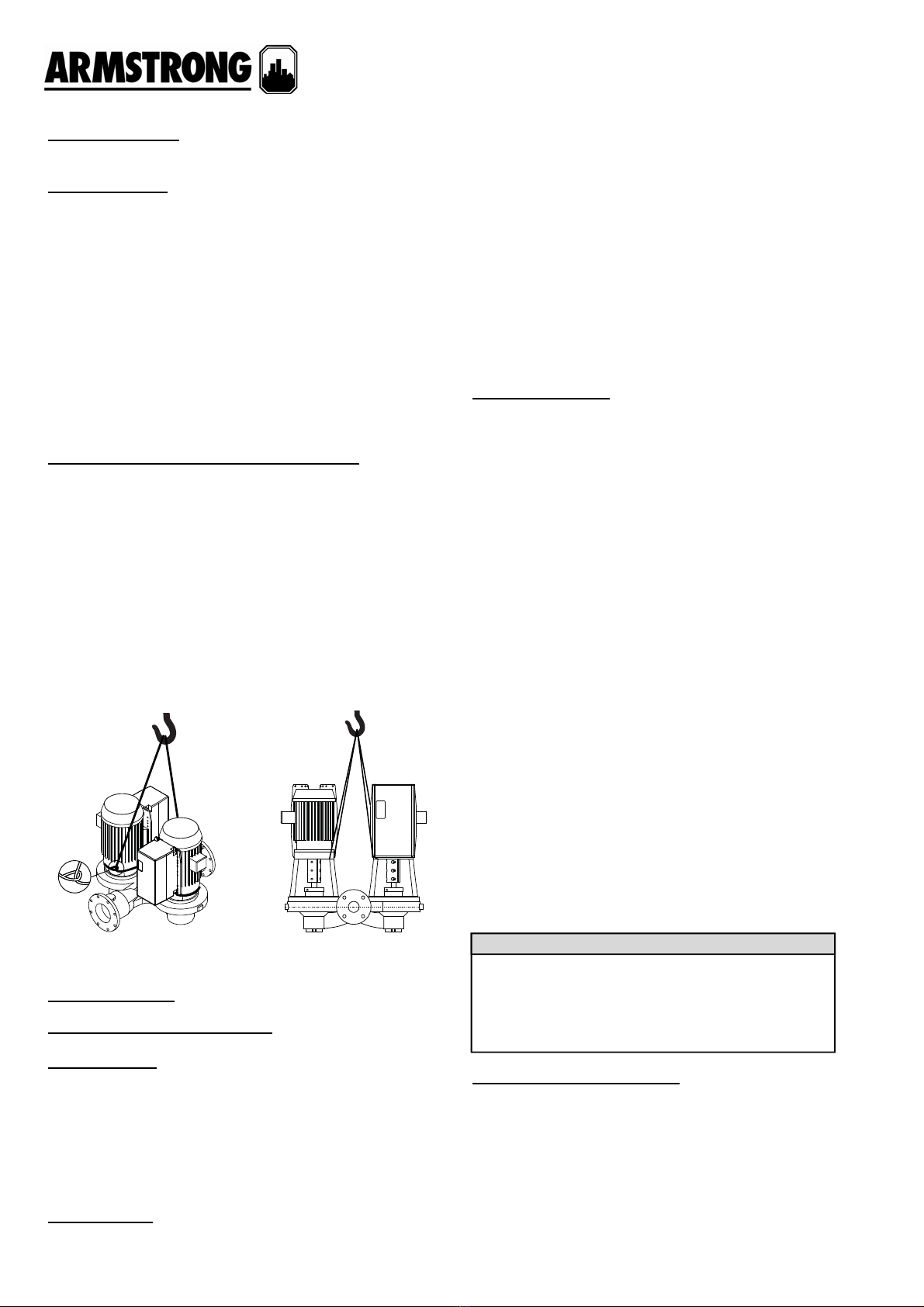

All Series 4302-IVS pumps contain a tapped hole in

the motor bracket above the discharge flange for

draining the well. Pipe this drain hole to a floor drain to

avoid overflow of the cavity caused by collecting

chilled water condensate or from seal failure.

IMPORTANT