9

• Wear safety glasses or eye shields to protect from

dust and debris.

• Wear ear plugs to protect from loud or high pitched

noises.

• Wear gloves to protect hands from burns if hydraulic

components become hot during operation.

• Never wear sandals or other light footwear when

operating or servicing the machine. Wear protective

footwear when handling heavy parts.

• Do not wear loose tting clothing which may

become entangled when operating or servicing the

machine.

Parking Safely

1. Position the machine on level ground.

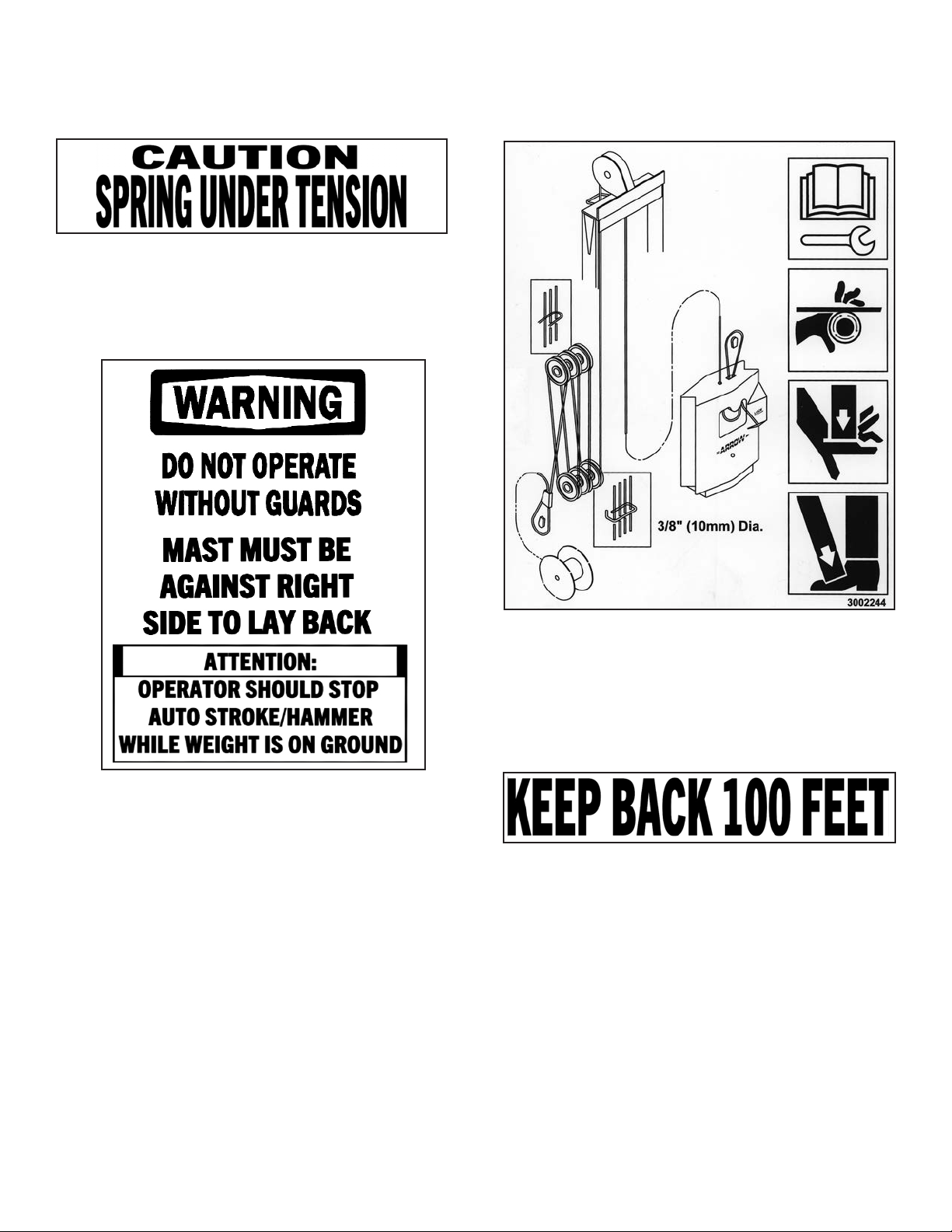

2. Fully shift the mast to the right.

3. Position the hammer and insert the hammer lock pin.

4. Fully lower the mast onto the mast rest and tilt the

mast to contact the ROPS (Roll-Over Protective

Structure).

5. Engage the park brake.

6. Turn the key switch to the OFF position and remove

the key from the switch.

• Do not allow anyone to operate the machine unless

they have rst read and understood the machine

operator manual.

• Do not allow anyone to operate the machine unless

they have rst read and understood the safety and

warning decals on the machine.

• The machine owner is responsible for training others

to safely operate the machine, and is responsible for

any injuries or harm which occurs while the machine

is being operated.

• Do not operate the machine inside enclosed areas

where carbon monoxide gas may build up.

• Before operating, replace any worn or damaged

safety decals.

• Before operating, thoroughly inspect the machine to

be sure all hardware (bolts, nuts, etc.) is installed and

tightened.

• Before operating, thoroughly inspect the machine

to be sure it is in working order. If the machine

is damaged or otherwise not in working order, do

not operate until it has been repaired by a qualied

technician.

• Do not operate the machine if you are under the in-

uence of alcohol, drugs, or medications which may

cause drowsiness.

• Do not allow children to operate the machine.

• Do not allow anyone who has not been trained to

operate the machine.

• Inspect the work area before operation to remove

any obstacles or mark them to avoid. Conrm no

lines or pipes or other objects are just beneath the

concrete surface.

• Conrm all guards are in place before operating.

• Keep hands, feet or other objects away from under-

neath the machine while operating.

• Never leave the machine unattended while the en-

gine is running.

• Position the machine on level ground or surface

when you are done operating.

• Allow the muer and engine to cool before touch-

ing.

• Keep the muer and engine area clean and free of

debris.

• Park the machine safely and disconnect the negative

battery terminal before performing any service.

• Do not allow anyone to service the machine unless

they have rst read and understood the machine

operator or service manuals.

• Do not allow anyone to service the machine unless

they have rst read and understood the safety and

warning decals on the machine.

• The machine owner is responsible for training others

to safely service the machine, and is responsible for

any injuries or harm which occurs while the machine

is being serviced.

• Always securely block the machine after raising to

inspect or service the machine.

Safety