CYC1000 User Guide www.arrow.com

Page | 2 January 2020

Table of Contents

Table of Figures ..................................................................................................................... 4

CYC1000 IoT / Maker Board.................................................................................. 5

1.1 About Arrow CYC1000 Board............................................................................................5

1.2 Useful Links.......................................................................................................................5

1.3 Getting Help......................................................................................................................6

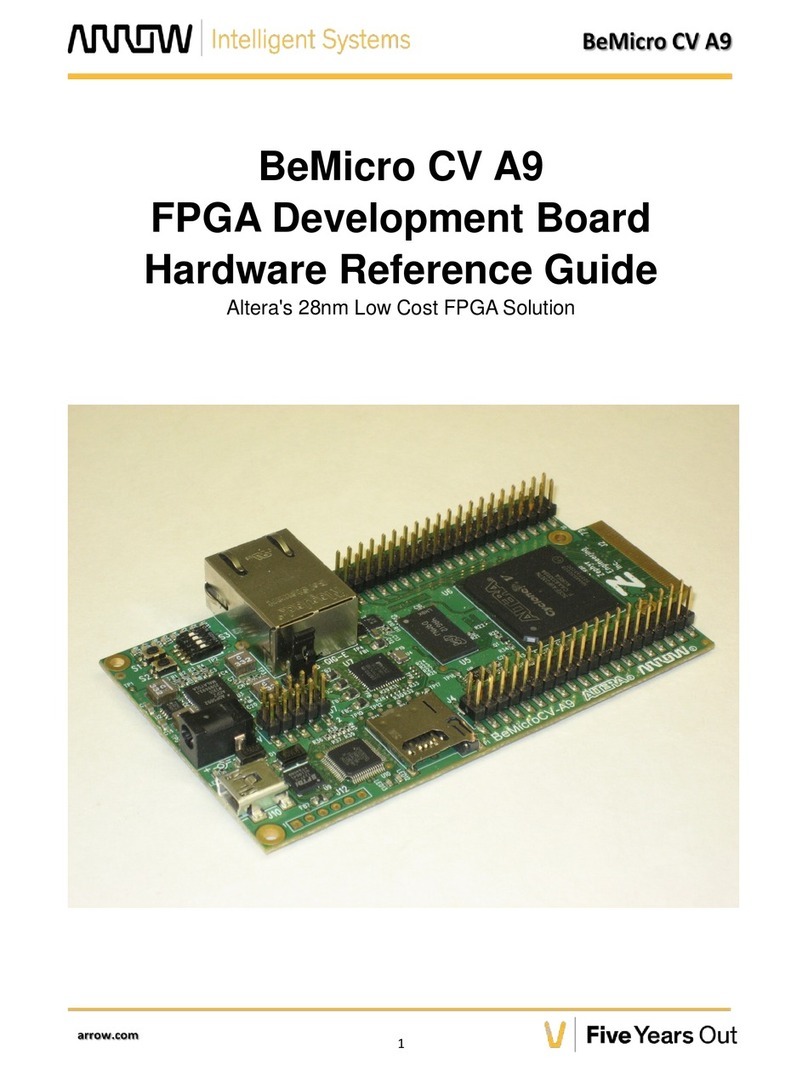

Introduction to the CYC1000 Board ...................................................................... 7

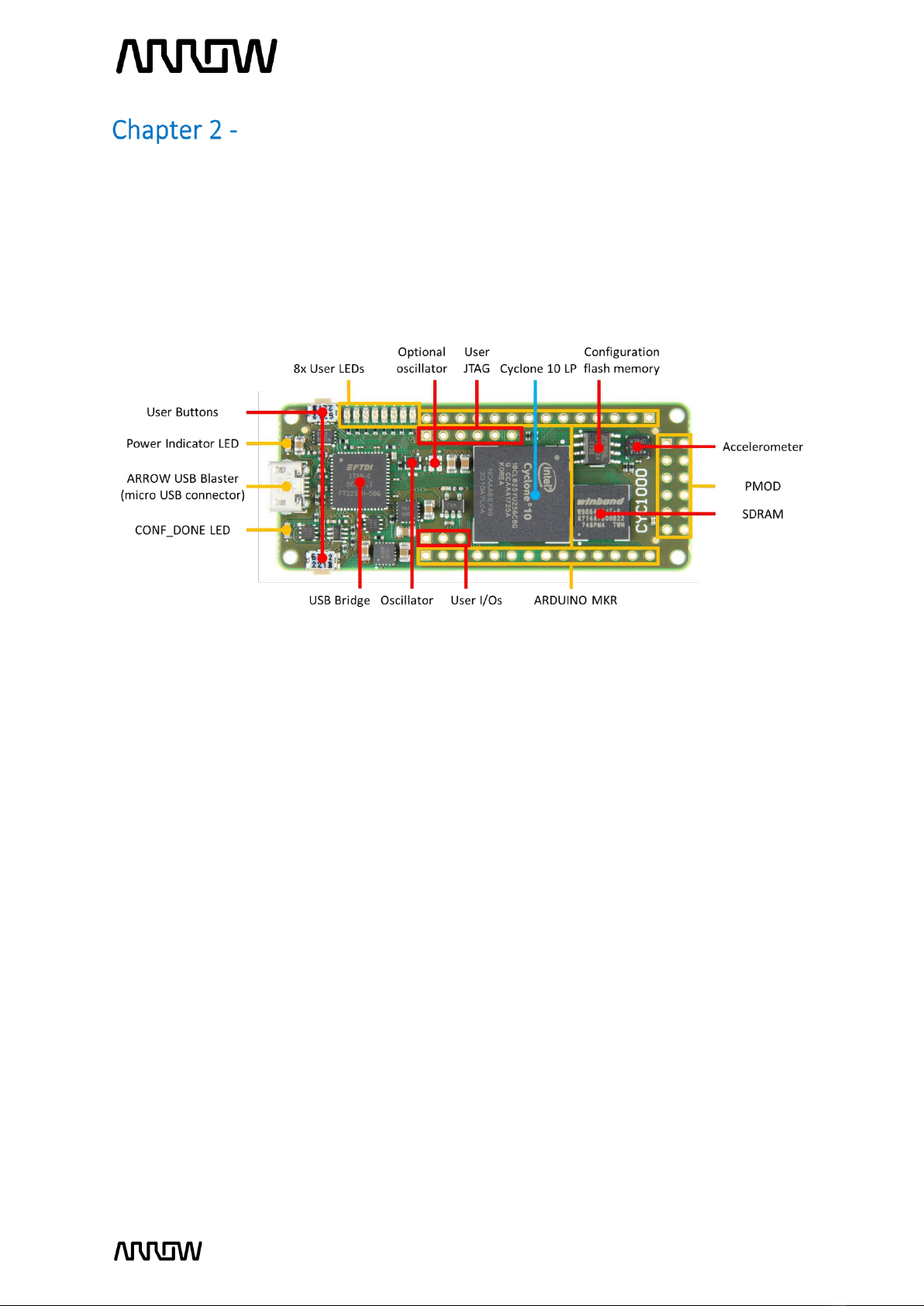

2.1 Layout and Components...................................................................................................7

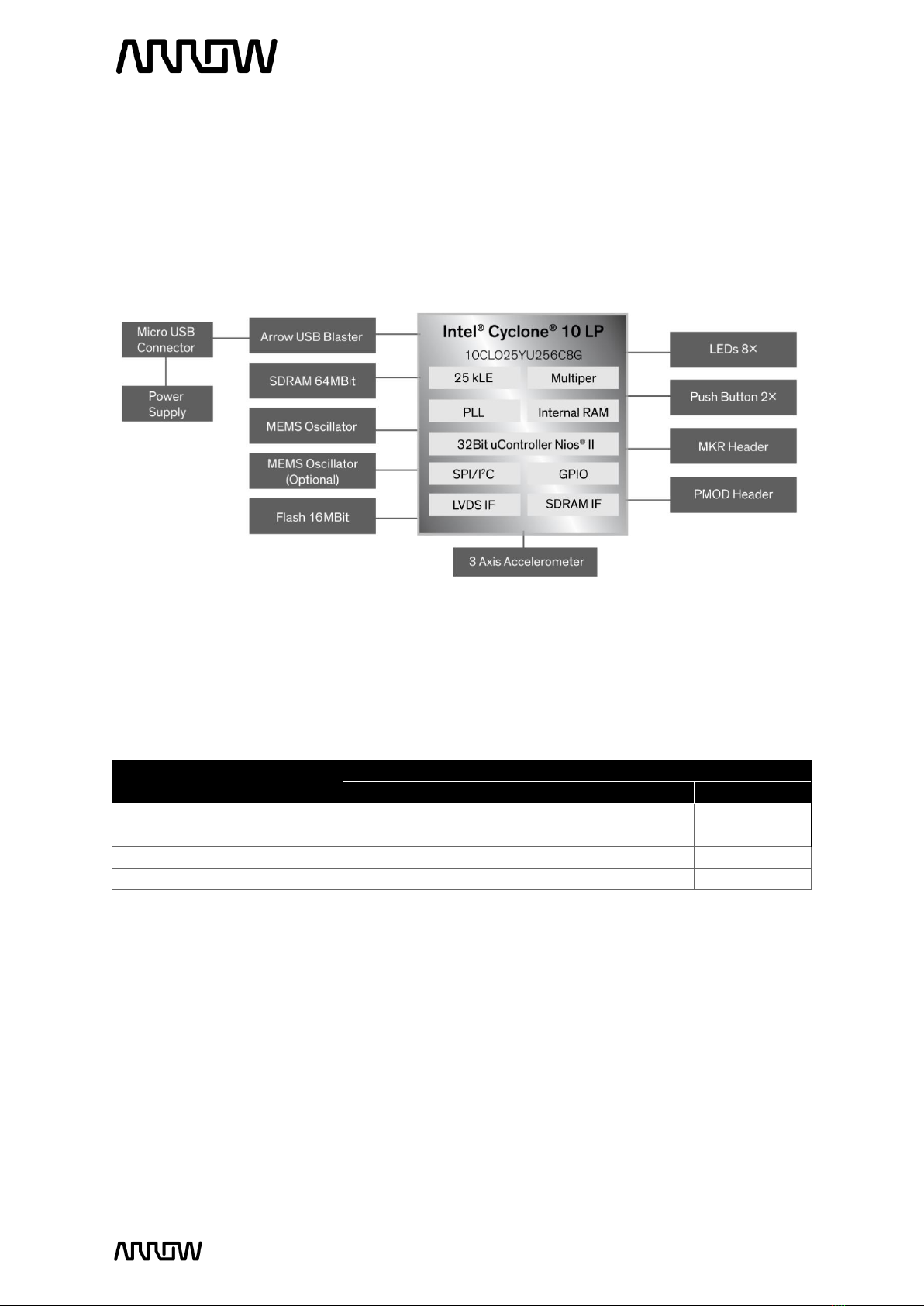

2.2 Block Diagram...................................................................................................................8

Connections and Peripherals of the CYC1000 Board............................................ 10

3.1 Board Status Elements....................................................................................................10

3.2 Clock Circuitry.................................................................................................................10

3.3 Peripherals Connected to the FPGA ...............................................................................11

3.3.1 LEDs.........................................................................................................................11

3.3.2 Push Buttons ...........................................................................................................12

3.3.3 Accelerometer.........................................................................................................12

3.3.4 SDRAM Memory......................................................................................................13

3.3.5 Serial Configuration Flash Memory ........................................................................14

3.3.6 Arduino MKR Connectors........................................................................................15

3.3.7 PMOD Connector ....................................................................................................16

3.3.8 User I/O...................................................................................................................17

3.3.9 Communication and Configuration.........................................................................17

3.3.10 Power Tree..............................................................................................................19

Software and Driver Installation......................................................................... 20

4.1 Installing Quartus Prime Software..................................................................................20

4.2 Installing Arrow USB Programmer2................................................................................21

New Project with CYC1000 ................................................................................. 24

5.1 Creating a new Blinky Project with CYC1000..................................................................24

5.2 Building a Blinky Project with CYC1000..........................................................................28

5.2.1 Block Diagram .........................................................................................................29

5.2.2 Components of the Design......................................................................................29

5.2.3 Catalog IP ................................................................................................................30

5.2.4 Create a PLL.............................................................................................................30

5.2.5 Create and Configure the PLL .................................................................................31