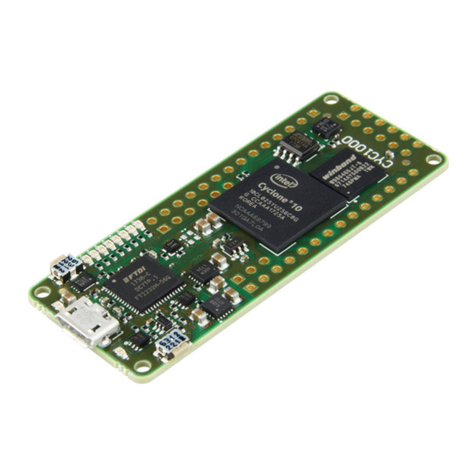

CYC5000 User Guide www.arrow.com

Page | 2 March 2023

Table of Contents

Table of Figures.......................................................................................................................................... 4

CYC5000 IoT / Maker Board ............................................................................................... 5

1.1 About Arrow CYC5000 Board .............................................................................................................................5

1.2 Useful Links ..............................................................................................................................................................5

1.3 Getting Help.............................................................................................................................................................6

Introduction to the CYC5000 Board................................................................................. 7

2.1 Layout and Components ................................................................................................................................... 7

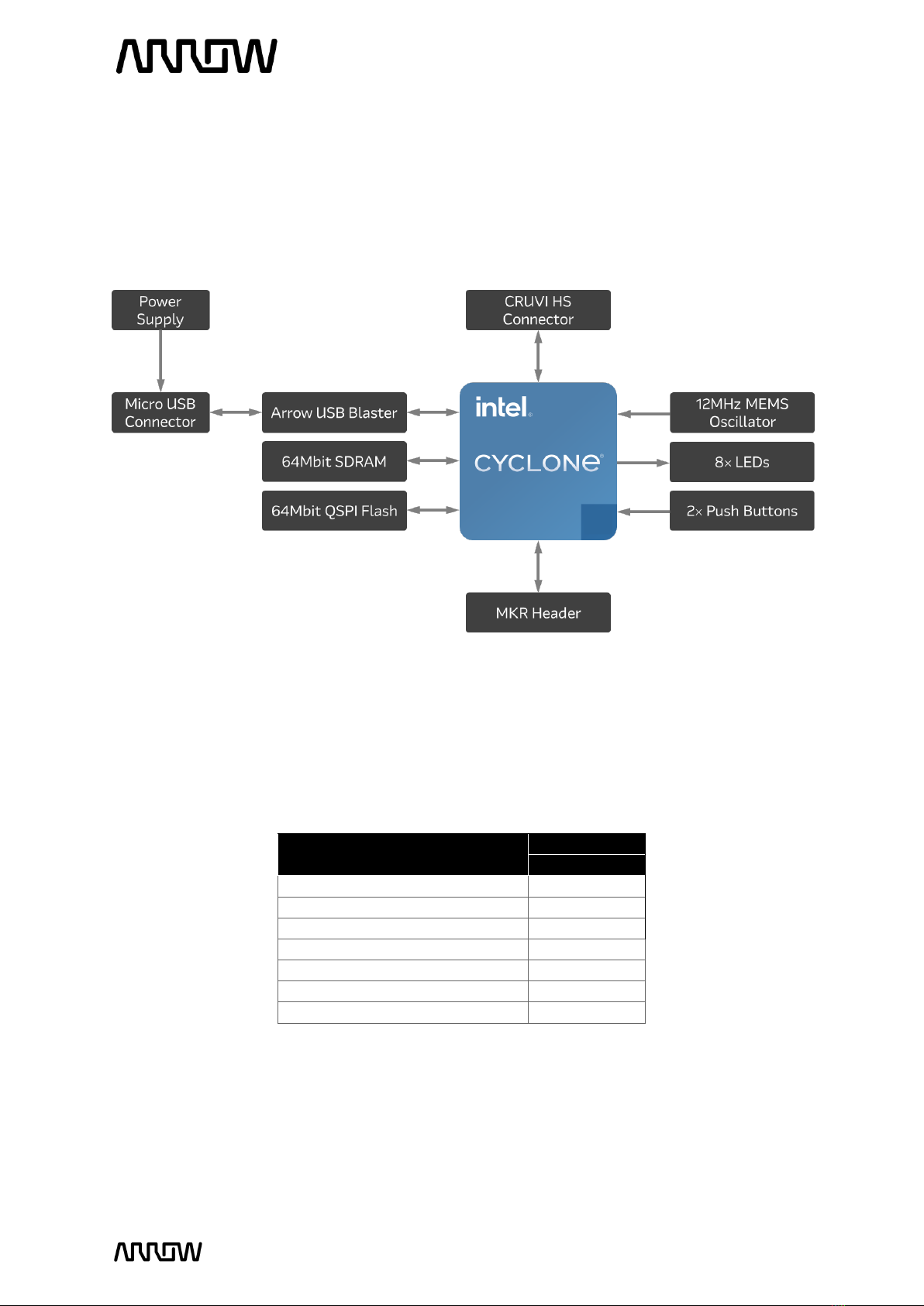

2.2 Block Diagram.........................................................................................................................................................8

Connections and Peripherals of the CYC5000 Board ................................................. 10

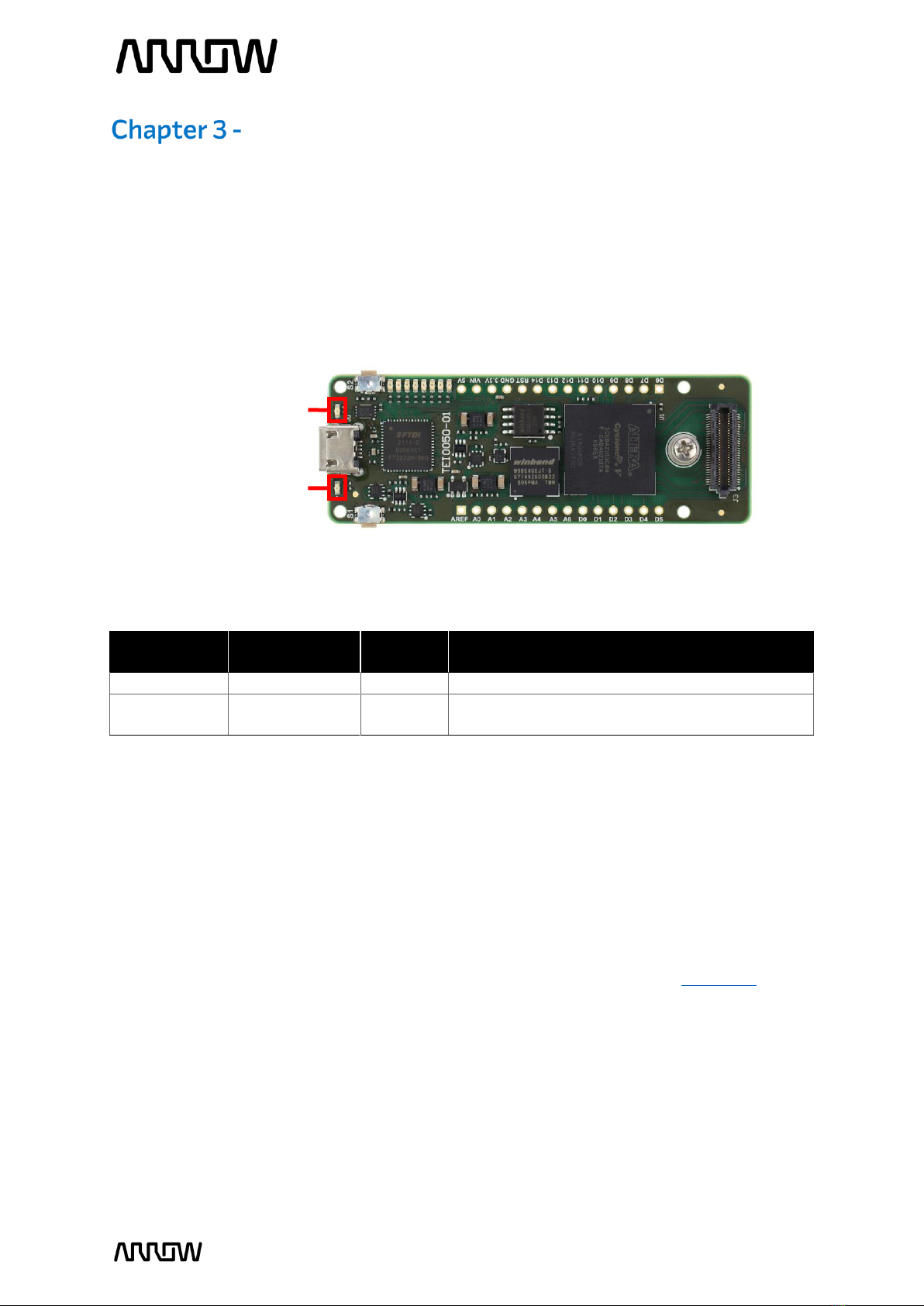

3.1 Board Status Elements.....................................................................................................................................10

3.2 Clock Circuitry ......................................................................................................................................................10

3.3 Peripherals Connected to the FPGA ..........................................................................................................11

3.3.1 Communication and Configuration...................................................................................................11

3.3.2 QSPI Configuration Flash Memory ...................................................................................................13

3.3.3 SDRAM Memory.........................................................................................................................................14

3.3.4 CRUVI HS Connector ...............................................................................................................................16

3.3.5 Arduino Header ..........................................................................................................................................18

3.3.6 LEDs .................................................................................................................................................................19

3.3.7 Push Buttons ..............................................................................................................................................20

3.3.8 Power Tree....................................................................................................................................................21

Software and Driver Installation..................................................................................... 23

4.1 Installing Quartus Prime Software............................................................................................................23

4.2 Installing Arrow USB Programmer2..........................................................................................................25

4.3 License ..................................................................................................................................................................... 27

New Project with CYC5000 ..............................................................................................29

5.1 Creating a new Blinky Project with CYC5000 .....................................................................................29

5.2 Building a Blinky Project with CYC5000................................................................................................33

5.2.1 Block Diagram............................................................................................................................................33

5.2.2 Components of the Design .................................................................................................................34

5.2.3 Catalog IP .....................................................................................................................................................34

5.2.4 Create and Configure PLL ....................................................................................................................34

5.2.5 Create and Configure the Counter..................................................................................................36

5.2.6 Create and Configure the Multiplexer...........................................................................................39

5.2.7 Adding the Components to the Schematic..................................................................................41

5.2.8 Connecting the Components .............................................................................................................43