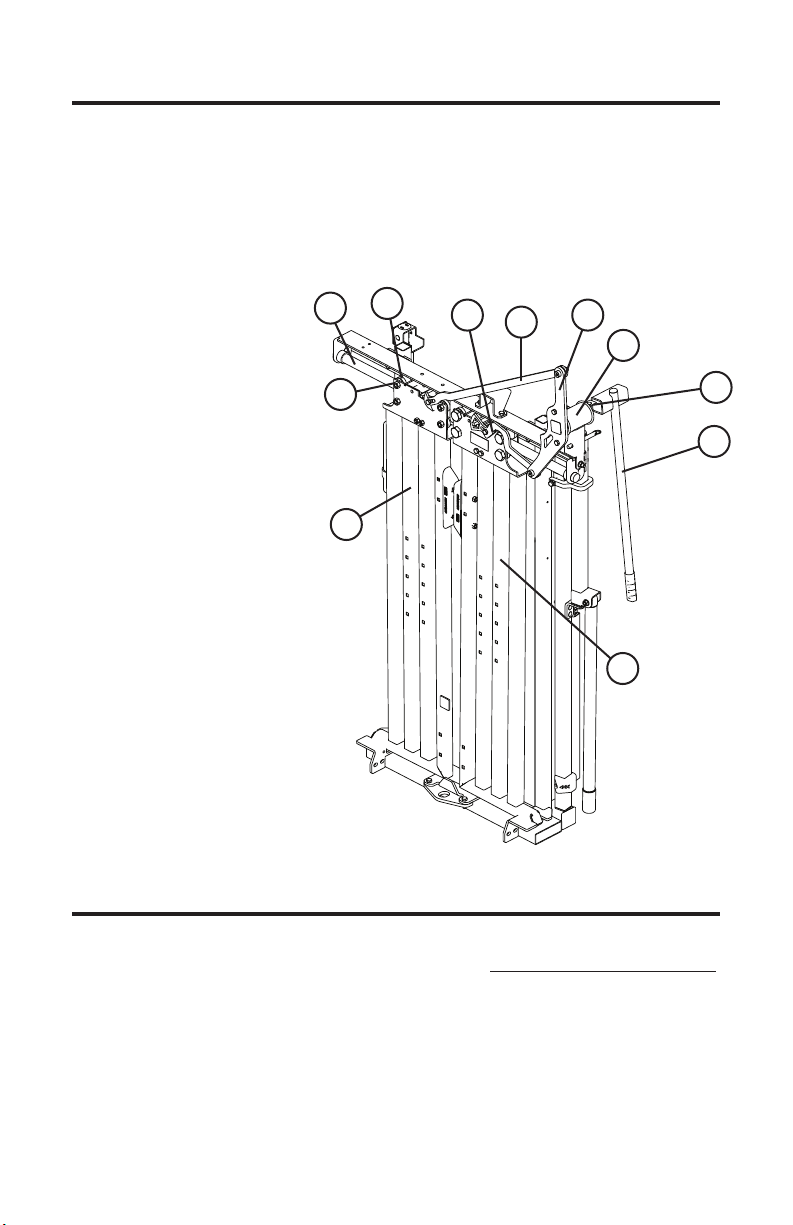

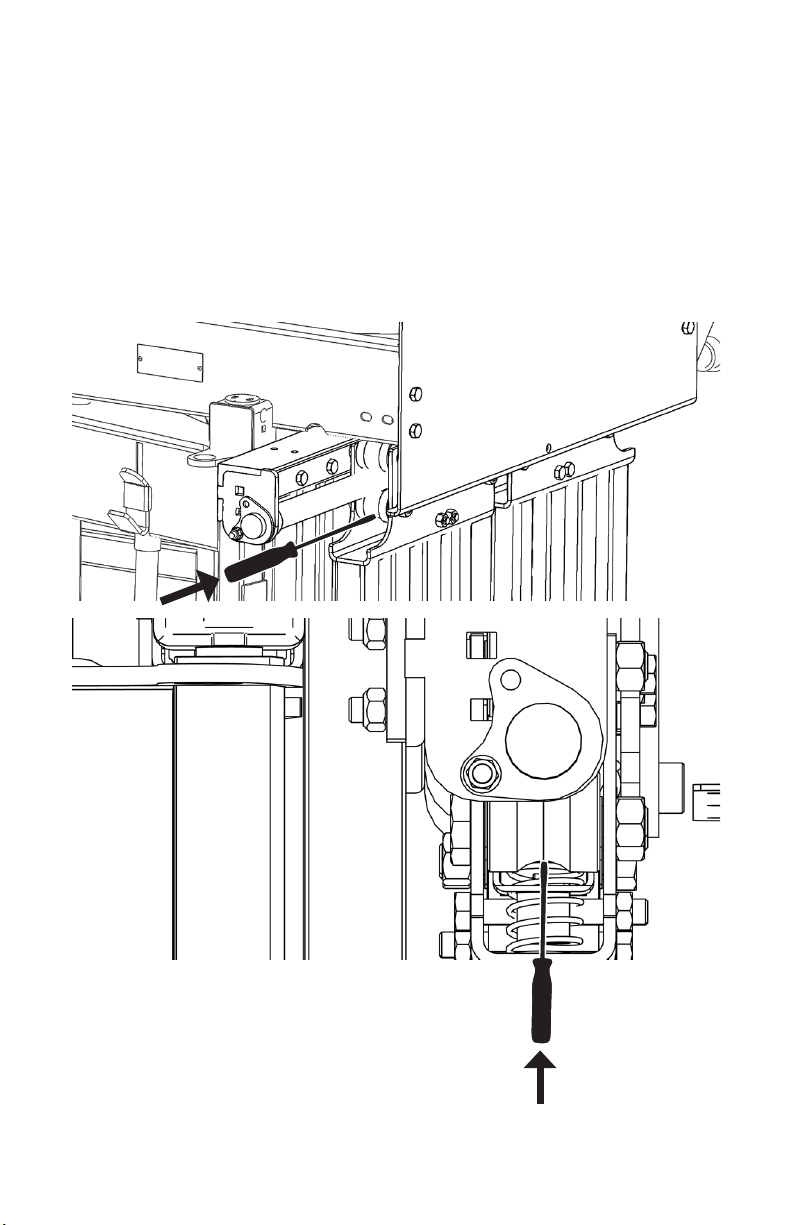

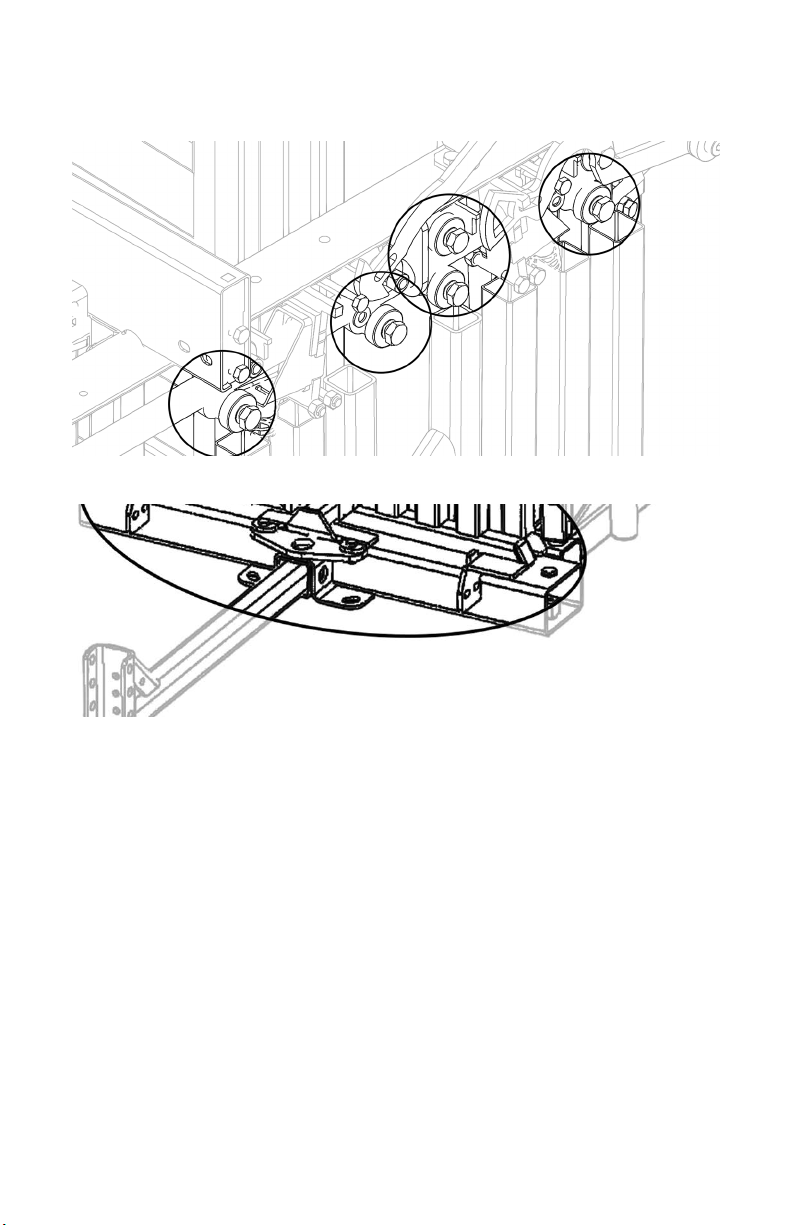

c. On the yoke gate, there is a short hammer and a long hammer between the handle

pivot and doors. These two hammers have a slot in them – check that there is free

movement for the bolt to move the entire length of this slot, and the lock nuts are

correctly tightened.

d. The door hammers also contact the release pins on the lock plates when the head

gate handle is pulled back. Ensure there is an air gap between levers and release

pins when yoke gate is being pushed or in an idle position.

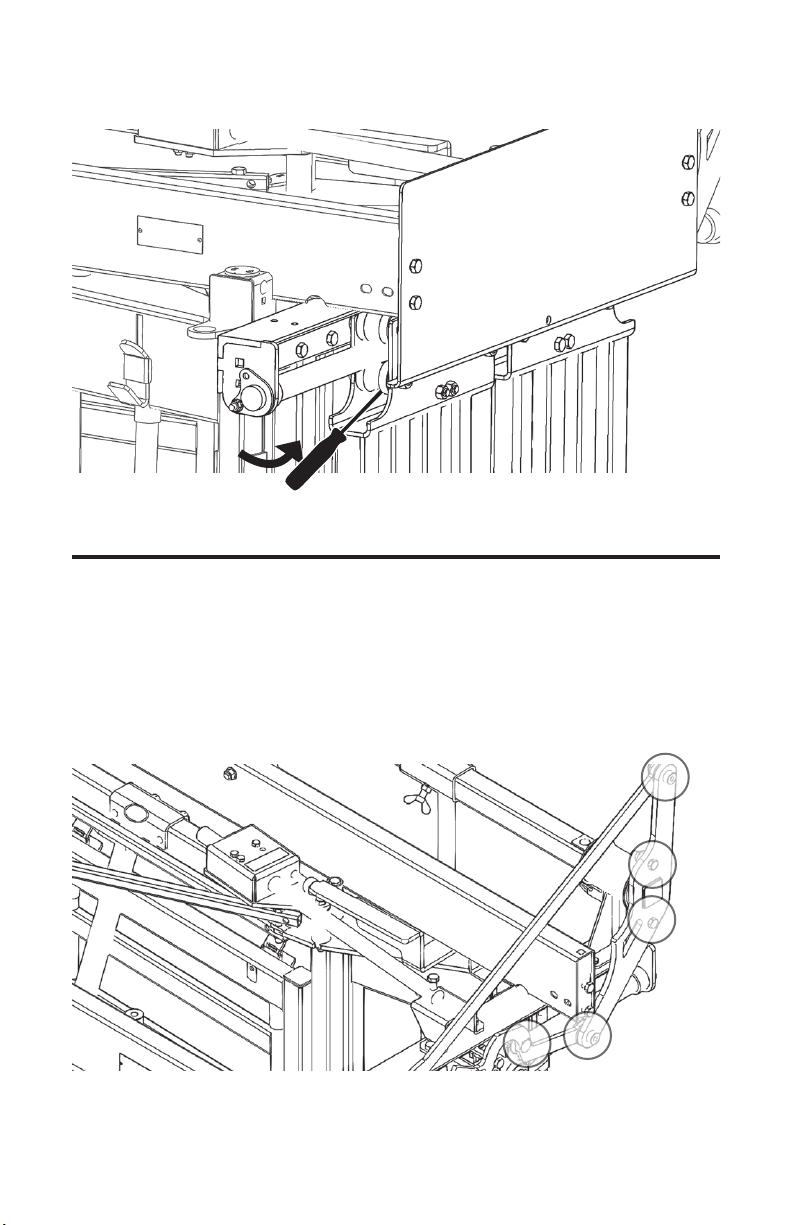

6. Check nuts and bolts on items and ensure that they are tightened correctly, and are not

binding.

7. All lock boxes and pivot points should be lubricated as needed with WD-40 Dry Lube.

WARRANTY

Your product must be registered to claim warranty, and to ensure that Arrowquip has the

required information to contact you in the event of a product or part recall. Any owner who

fails to register their product warranty with Arrowquip through their Authorized Arrowquip

Dealer voluntarily voids their warranty. Arrowquip will repair or replace products or parts of a

product that prove defective due to manufacturer defect during the Warranty Period, at their

sole discretion. This excludes defects resulting from normal wear and tear or product misuse.

Warranty does not cover corrosion. NOTE: Any modication, in any fashion, to any Arrowquip

equipment immediately voids the product warranty. This includes the parts contained therein.

Eg. If a modication is made to the squeeze mechanism in a squeeze crush, and the sternum

bar is bent afterwards, warranty for the damaged part, the sternum bar, contained in the

modied equipment, the squeeze crush, is void. In addition, any remaining warranty for the

squeeze crush and other parts contained therein, including, but not limited to, the yoke gate,

locking system, Q-Catch system, and rollers, is null and void.

REGISTER FOR WARRANTY NOW:

Online: arrowquip.co.uk/product-registration

WARRANTY | 7