IBC Technologies Inc. 1-844-432-8422 |www.ibcboiler.com

120-538E0 -October 20, 2023 - Released Document 2 of 6

Note

This kit does not come with a replacement burner.

Please clean and reuse the original burner as directed in Exchanging the Burner on page 4.

If the burner needs to be replaced, order P-1519.

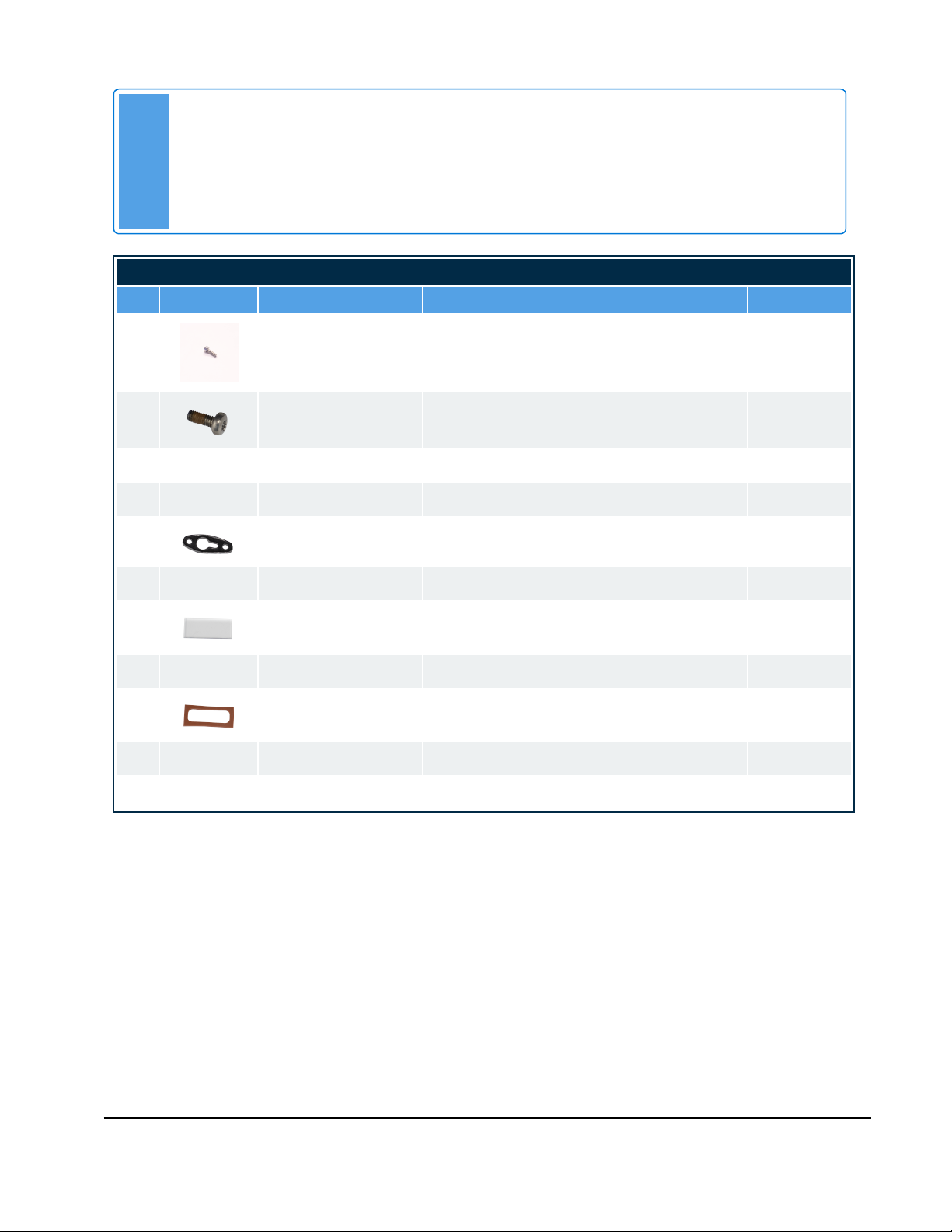

Heat Exchanger Lid -CX 150

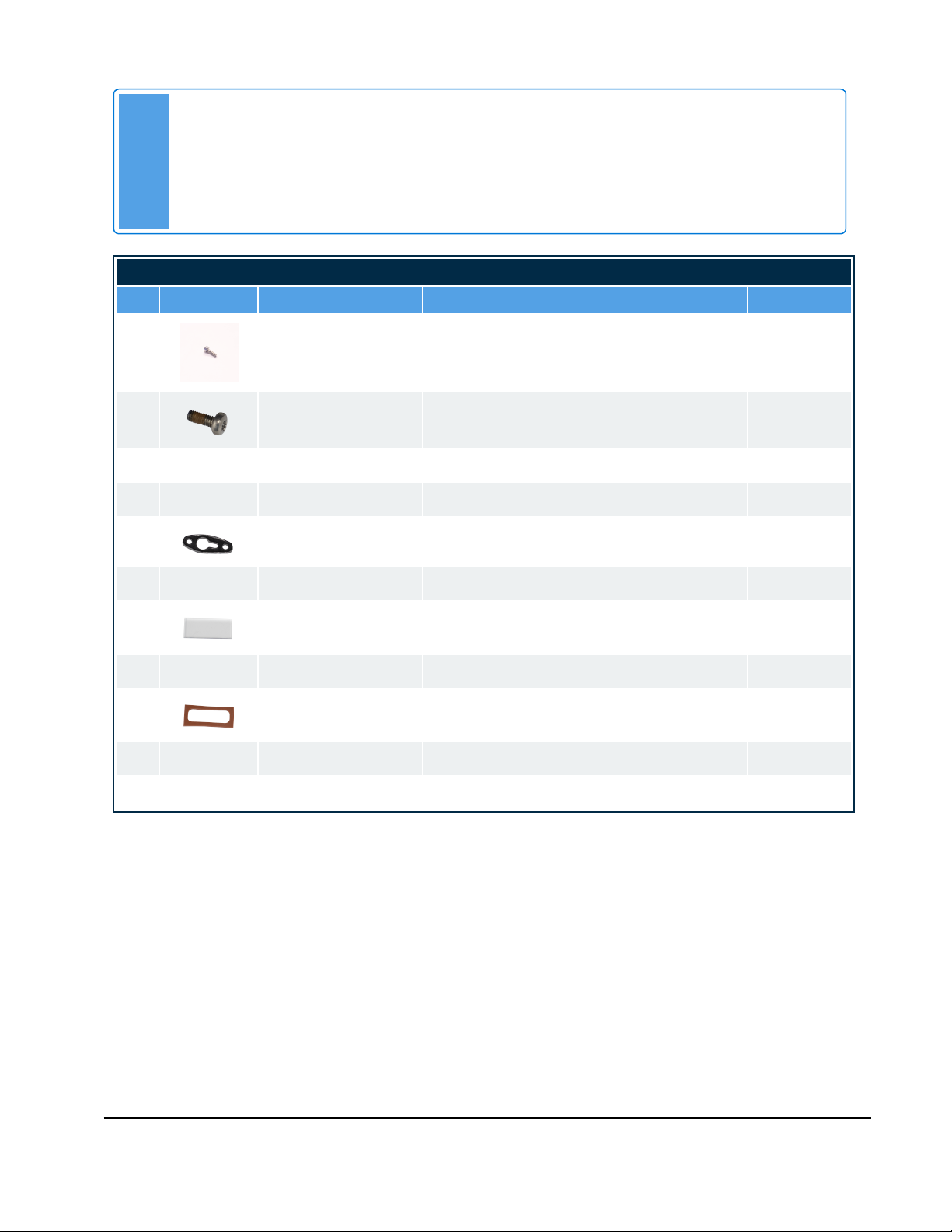

Part # Description Quantity

150-012 Screw, SHC, S/S, M3x10 2

150-260 Screw, 6 T/ Pan S/S, M4-0.7x10mm 8

170-126 Lid, Burner, VC45 1

240-182 Ignitor, VC (Kanthal APM 3.0) 1

250-050 Gasket, Ignitor 1

250-057 Housing, Viewport 1

250-059 Glass Insert, Viewport 1

255-023 Gasket- Sight Glass To Lid, SL 1

255-025 Gasket- Viewport Upper 1

255-141 Gasket, Burner VC45&60 1

255-152 Refractory, VC150 1

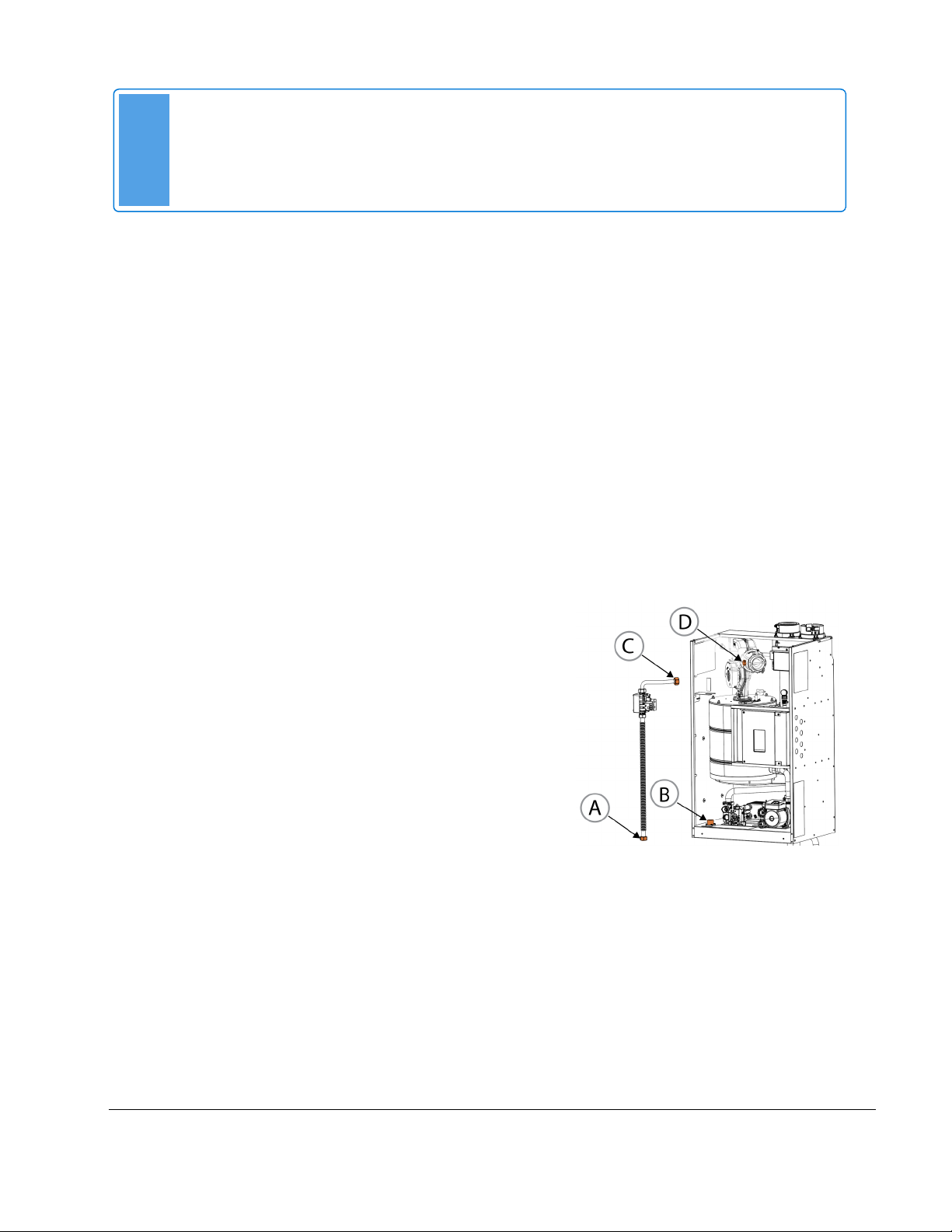

When to Install the P-1627 Heat Exchanger Lid Replacement

Kit

Install the P-1627 kit if you need to replace a heat exchanger lid that has been damaged.