7

10.01.2019 explosion-proof extraction arms ERGO-L/Z-{2;3;4}/Ex

7. Operational Use

Construction of the device assures reliable function without continuous routine technical su-

pervision. Adjustment of the ERGO extraction arms consists in setting the frictional brakes

that are in each joint. Frictional brakes provide self-supporting properties and position balan-

ce of the device during the function. Tightening the nut tension (upon the frictional element)

increases the friction moment, whereas its releasing reduces the friction.

The brake adjustment in the following joints ought to be executed in such a way that provi-

des stability and self-supporting features of the extraction arm (which is important to keep the

stable arm position), whereas on the other hand, this cannot cause any excessive friction re-

sistance while User is changing the arm position.

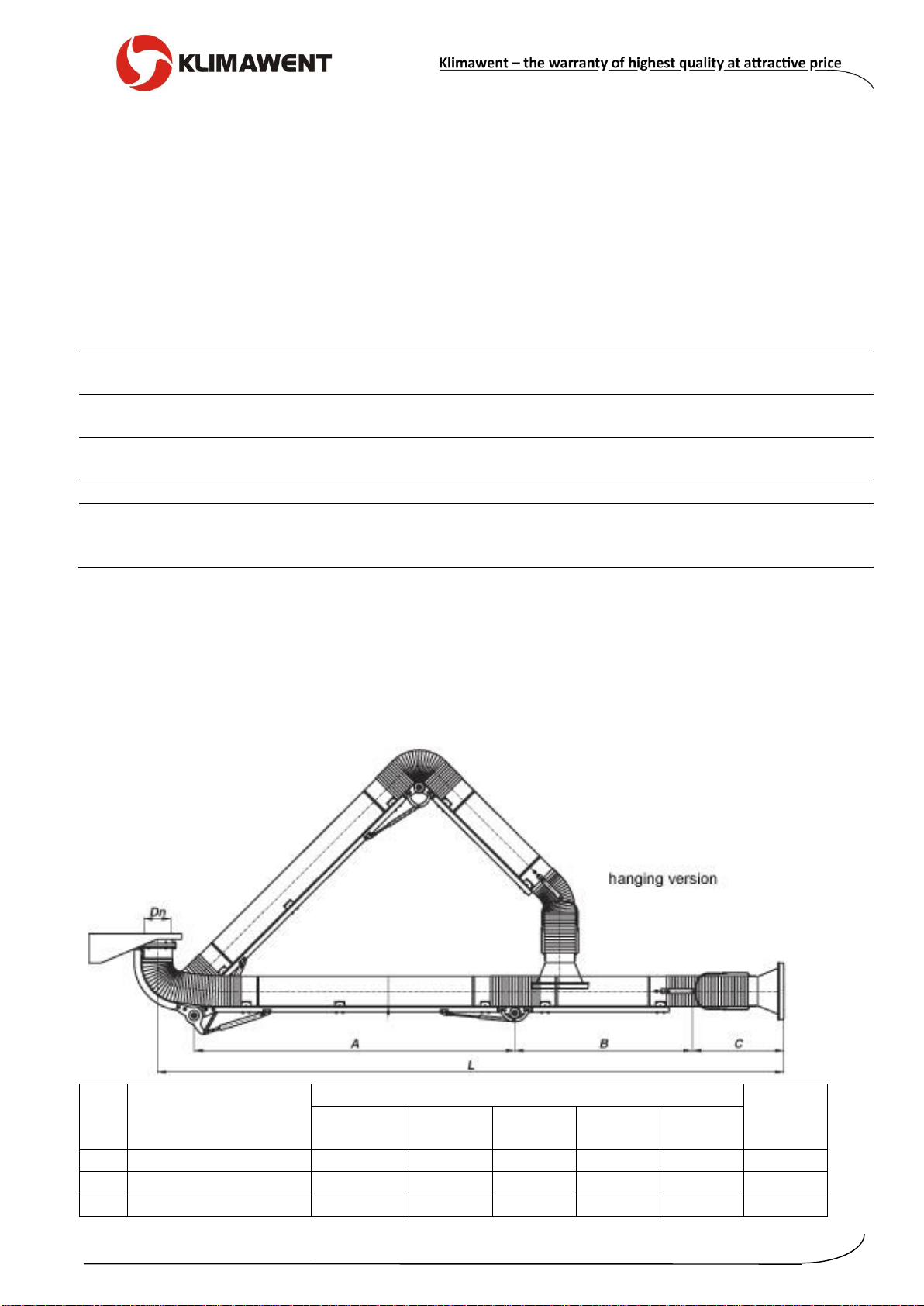

Having completed the adjustment, tighten up the counter-nuts. Placement of the adjustment

nuts is illustrated in dimensional drawings of the extraction arms.

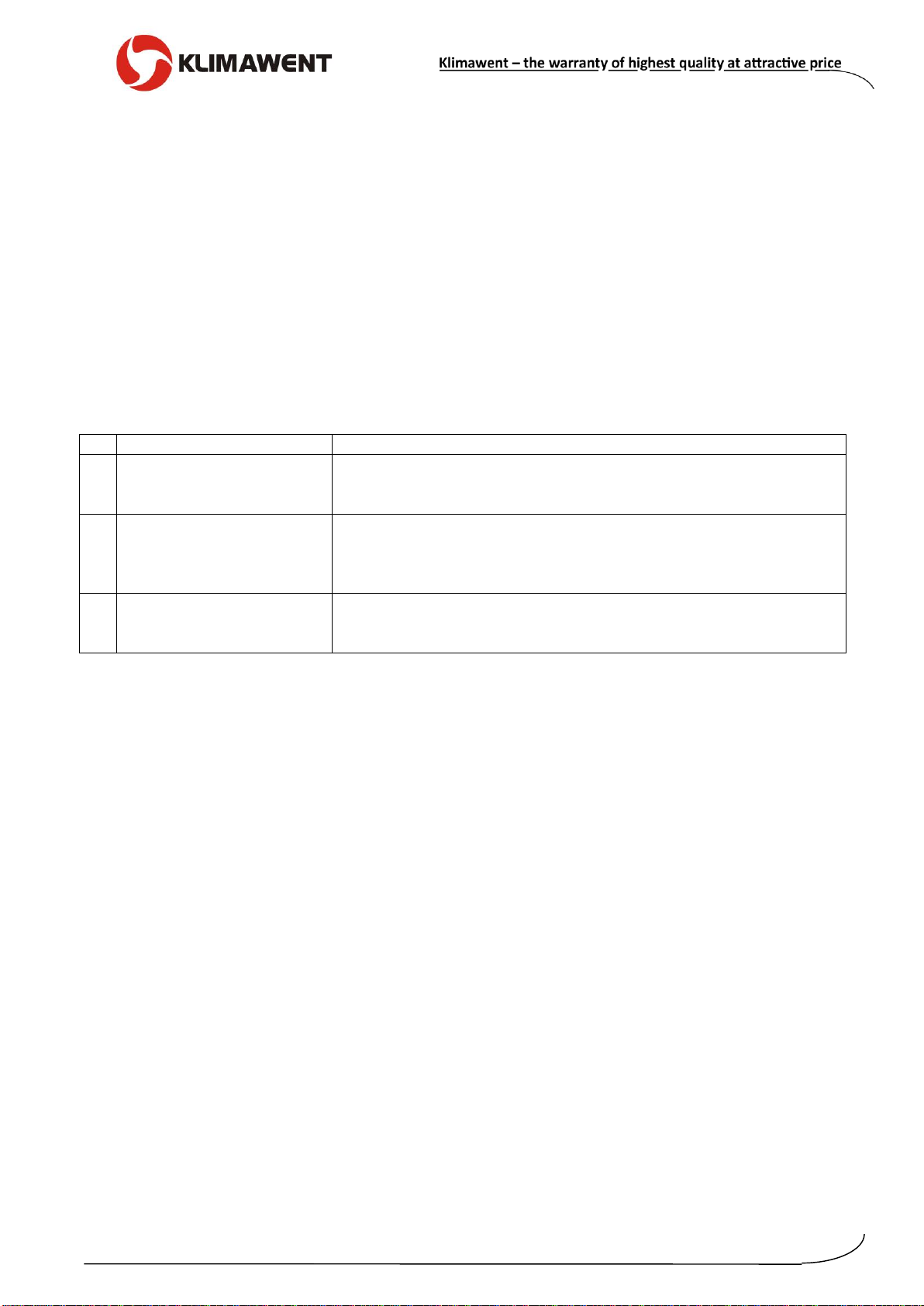

8. Troubleshooting Guide

Table No.1

possible reason corrective action

Improperly adjusted frictional brake.

Increase the tension upon frictional disks of the brake in the joint

by tightening the adjustment nuts.

The rotation axis of the arm is not positioned vertically.

Carry out the positioning of the mounting flange of the

ERGO/Ex extraction arm to set the rotation axis vertically.

Drop in the air suction rate

Improper impeller rotation sense of the extraction fan.

Change the phase connection sequence (3-phase motor only).

9. Maintenance

Maintenance consists in following steps executed periodically:

In case when the extraction arm losses the self-supporting property in the joint system

–undertake its adjustment.

Every three months lubricate the swivel with solid grease (lubrication nipple is placed

on the swivel collar.

Periodically, (more frequently than once a half a year of use) undertake technical revi-

sion and replace the faulty or worn out elements.

Systematically check the cleanness of the extraction arm, remove the dust that built

up inside and on the device surface, in order to avoid self-ignition of the deposited im-

purities. Cleaning can be executed beyond the area of explosion hazard.

In case of replacement necessity of any element in the extraction arm (i.e. gas

spring, hose, pipe segments, hood, grounding cables), use original parts only,

delivered by KLIMAWENT S.A.

Any repairs ought to be executed in rooms not being in explosion hazard zone.

After every disassembling, assembling, check the continuity of the grounding

cables.

Periodically, (depending on the conditions of work) measure the surface resi-

stance of the hoses –it should not exceed 1 GΩ. Execute the measuring accor-

ding to the EN 13463-1 Clause 7.4.4 a. Similarly, measure the resistance of the

device (continuity of the grounding cables) –should not exceed 1Ω. Collect the

electrical measuring results in a file.