Bend-Tech Dragon mAchines User manual

Part 1 of 1

Dragon Troubleshooting Guide

Revision 002 | English ©2021 Bend-Tech LLC

Dragon CAM v1.0

Dragon mAchines

ii Bend-Tech Dragon

Troubleshooting Guide

©2021 Bend-Tech LLC

All rights reserved. The information in this manual is subject to change without notice.

Bend-Tech LLC strives to produce the most complete and accurate information regarding

its products. We are constantly working to improve and advance our products to increase

performance, user satisfaction and experience. Bend-Tech LLC assumes no responsibility for

errors or omissions regarding this manual. Bend-Tech LLC assumes no liability for damages

resulting from the use of the information contained in this publication.

Troubleshooting Guide iiiBend-Tech Dragon

Dragon Machines

Dragon Troubleshooting Guide

Revision 002

English

Original Instructions

October 2021

Bend-Tech LLC

729 Prospect Ave.

Osceola, WI 54020 USA

(651) 257-8715

www.bend-tech.com

iv Bend-Tech Dragon

Troubleshooting Guide

Contents

Contents

Contents..........................iv

Limited Warranty .................. viii

Customer Satisfaction Commitment. . . . . ix

Customer Service. . . . . . . . . . . . . . . . . . . ix

Alerts ............................x

Glossary..........................xii

Machine Capabilities ............... xiv

01

Troubleshooting .................... 15

1.1 How to Send a Support Session ... 15

02

Gate Troubleshooting ............ 16

2.1 Dragon Gate Troubleshooting ..... 16

2.1.1 Eccentric bearing on the Gate is

sticking ....................... 16

2.1.2 Gate is Binding ............ 16

2.1.3 Gate is Loose. . . . . . . . . . . . . . 16

2.1.4 Gate is not Operating Smoothly 17

2.1.5 Play in the Gate ............ 17

2.1.6 Gate Jaws are not Operating

Smoothly...................... 17

2.2 Adjusting the Gate Eccentric Bearing 18

2.2.1 Before Beginning ........... 18

2.2.2 Remove Safety Guards (Powered

Gate Only) .................... 18

2.2.3 Remove the Drive Gear (Powered

Gate Only) .................... 19

2.2.4 Remove the Gate. . . . . . . . . . . 19

2.2.5 Adjust the Eccentric Bearing .. 19

2.2.6 Re-install the Gate.......... 20

2.2.8 Position Drive Gear (Powered Gate

Only) ......................... 20

2.2.9 Re-attach the Safety Guards

(Powered Gate Only) ............ 20

2.3 Adjusting the C-Axis Backlash ..... 20

2.4 Calibrating Coordinated Rotation... 21

3.4.1 Open the Wizard ........... 21

3.4.2 Dragon Calibration Wizard. . . . 21

2.4.3 Begin Calibration ........... 22

2.4.4 Computer Setup. . . . . . . . . . . . 22

2.4.5 Ready the Trolley........... 22

2.4.6 Begin Homing Process ...... 23

2.4.7 Toolhead Level............. 23

2.4.8 Chuck. . . . . . . . . . . . . . . . . . . . 23

2.4.9 Powered Gate ............. 23

03

Laser Light & Engraver

Troubleshooting ..................... 24

3.1 Laser Light Troubleshooting....... 24

3.1.1 Laser Light does not Align with the

End of the Material .............. 24

3.1.2 Laser Light Failure.......... 24

3.2 Engraver Troubleshooting ........ 25

3.2.1 Engraver is Marking too Heavy or too

Light ......................... 25

3.2.2 Engraver is not Turning On ... 25

3.3 Setting Engraver Air Pressure ..... 25

3.3.1 Engraver Bleeder Valve ...... 25

04

Torch & Cutting

Troubleshooting ..................... 26

Troubleshooting Guide vBend-Tech Dragon

Contents

4.1 Cutting and Torch Troubleshooting . 26

4.1.1 Copes are Not the Same

Rotation ...................... 26

4.1.2 Poor Cut Quality or Accuracy. . 27

4.1.3 Round Holes are Cutting as

Ovals......................... 27

4.1.4 Machine Cuts and then Returns to

Previous Action................. 27

Square Material ................ 27

4.1.5 Jagged Cuts. . . . . . . . . . . . . . . 28

4.1.6 Torch Not Firing ............ 28

4.1.7 Torch is set too High ........ 28

4.1.8 Torch is Colliding with the

Material....................... 28

4.2 Grounding the Torch............. 29

4.3 Support Beam and Rail Alignment .. 30

4.3.1 Checking the Straightness and Level

of the Support Beam............. 30

4.3.2 Truing the Dragon Support Beam31

4.3.3 Rail Splices ............... 31

05

Material Support Lift

Troubleshooting ..................... 32

5.1 Material Support Lift Troubleshooting 32

5.1.1 Material Support Lift is Colliding with

the Rail ....................... 32

5.1.2 Material Support Lift is Not

Homing ....................... 32

5.1.3 Material Support Lift is Pausing at

the Wrong Time ................ 32

5.1.4 Material Support Lift is too High 32

5.1.5 Material Support Lift is Bottoming

Out .......................... 33

5.2 Material Support Lift Settings In Bend-

Tech 7x.......................... 33

5.2.1 Change the Support Lifter Gap 33

5.2.2 Adjusting Lifter Trigger Pause . 33

5.2.3 Material Support Lift Support

Retraction Settings .............. 33

5.2.5 Disabling the Material Support

Lift........................... 33

5.3 Material Support Lift Retraction

Adjustment ....................... 34

06

Trolley & Chuck

Troubleshooting ..................... 35

6.1 X-Axis Motor Troubleshooting ..... 35

6.1.1 X-Axis Will Not Jog ......... 35

6.1.2 Trolley is Binding while Jogging at

Full Speed. . . . . . . . . . . . . . . . . . . . . 36

6.1.3 X-Axis Motor is Skipping Steps 36

6.2 Adjusting Trolley Eccentric Bearings 36

6.3 X-Axis Backlash Adjustment ...... 38

6.4 Chuck Troubleshooting .......... 38

6.4.1 Chuck is Skipping Steps ..... 38

6.4.2 Chuck is not level when in the Load

Position....................... 38

6.5 Removing and Cleaning Chuck Jaws 39

6.6 Removing The Chuck............ 39

6.7 Cleaning The Chuck............. 40

6.8 Y-Axis Backlash Adjustment....... 40

07

Control Box Troubleshooting 42

7.1 Control Box Troubleshooting ...... 42

7.1.1 Motor is not Responding ..... 42

7.1.2 Machine is not Powering On .. 42

vi Bend-Tech Dragon

Troubleshooting Guide

Contents

7.1.3 Smooth-stepper is not Connecting to

the Computer .................. 42

7.1.4 Axis is not Responding or is

Responding Incorrectly........... 42

7.1.5 No Power to the Control Box .. 43

7.1.6 Unknown Failure within the Control

Box .......................... 43

7.1.7 Control Box is Outdated. . . . . . 43

7.2 Replace the Motor Driver ......... 43

7.3 Replacing the Control Box Power

Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . 44

7.4 Replacing the Smooth-stepper. . . . . 45

7.5 Replacing Control Box Fuses. . . . . . 45

7.6 Re-seating the Breakout Board .... 46

7.7 Replacing the Control Box ........ 46

08

Sensors Troubleshooting ...... 49

8.1 Sensor Overview ............... 49

8.2 Checking a Sensor.............. 49

8.3 Inspecting Sensor Cables ........ 50

8.4 Setting a Proximity Sensor........ 50

8.5 A-Axis and Z-Axis sensors ........ 51

09

Connections............................ 52

9.1 Troubleshooting ESS Connections . 52

9.1.1 ESS Failure to Connect ...... 52

9.2 Connection Lost While Machine is

Running ......................... 53

9.3 Ethernet Connections. . . . . . . . . . . . 54

10

Troubleshooting Mach3 ......... 56

10.1 Diagnostics in Mach3........... 56

10.1.1 Mach3 License Data ....... 56

10.1.2 Coordinating Dragon Designations

With Mach3.................... 56

10.1.3 Dragon Axis vs. Mach3

...................... 57

10.1.4 Testing Homing Sensors in

Mach3........................ 57

10.1.5 Jogging With Mach3 ....... 57

10.2 Mach3 Troubleshooting ......... 58

11.2.1 Limits 3, 4, and 5 triggered

in Mach3 and Emergency Mode

Activated...................... 58

11.2.2 “Emergency” Box is Flashing Red

and Machine is Unable to Home. . . . 58

10.3 Reviewing G-Code in Mach3 ..... 58

10.4 Prioritizing Mach3 on the Computer 58

10.5 Opening Mach3 ............... 59

10.6 Jogging in Mach3 ............. 60

10.6.1 Jogging During Calibration .. 60

10.6.2 Jogging Between Projects ... 61

10.7 Determining Machine Status in

Mach3 .......................... 61

10.8 MDI (Alt-2) Tab................ 62

10.8.1 Input Text Box ............ 62

10.9 Diagnostics (Alt-7) ............. 62

10.9.1 External Signals .......... 62

10.10 Ports and Pins ............... 63

10.11 Limit Switch is Triggered in Mach3 64

10.12 Leaving Mach3 Open.......... 64

10.13 Diagnosing an E-Stop in Mach3. . 65

Troubleshooting Guide viiBend-Tech Dragon

Contents

10.14 Calculating Run Time in Mach3 .. 65

10.15 Restarting a Job in Mach3 after Torch

Failure .......................... 66

10.15.1 Editing the Macro......... 66

10.15.2 Restarting the Job ........ 67

10.16 Diagnosing Sensor, Cable, and Control

Box Problems..................... 68

10.16.1 Diagnosing a Sensor Issue . 68

10.16.2 Checking the Control Box .. 68

10.16.3 Checking Sensors ........ 68

10.16.4 Reading ESS LED Status

Codes ........................ 69

10.16.5 Ethernet Jack LED Lights .. 70

10.17 Running Warp 9 Utility ......... 71

10.18 Mach3 Lost Communications while

Operating ........................ 71

10.19 Other Mach3 Errors ........... 72

10.19.1 Invalid Bootloader Signature 72

10.19.2 CryptoMemory Error ...... 72

viii Bend-Tech Dragon

Troubleshooting Guide

Limited Warranty

Limited Warranty

Covering Bend-Tech Dragon

Bend-Tech LLC provides a limited warranty on all new Dragon machines that are manufactured

directly or under license by Bend-Tech LLC, and sold by Bend-Tech LLC or its approved

distributors.

Warranty Coverage

Each Bend-Tech Dragon machine is warrantied by the manufacturer against defects in material

workmanship for 12-months. The warranty period commences upon delivery of the Dragon

machine to the customer’s facility.

Repair or Replacement Only

The Manufacturer’s sole liability, and the Customer’s exclusive remedy under this warranty

shall be limited to repairing or replacing the defective part. Repair or replacement of parts

is at the sole discretion of the manufacturer. The Customer is responsible for warranty parts

installation. Bend-Tech does not provide warranty service labor.

Limits

This warranty does not cover components subject to wear due to normal use of the machine

such as belts, lights, tooling etc. This warranty is void if Bend-Tech LLC has determined any

failure is the result of mishandling, abuse, misuse, improper installation, improper storage,

become void or limited in the event that hardware changes or adaptations are made to the

machine.

Software

The standard 2-year software maintenance plan is included with the purchase of a Dragon.

Before the 2-year maintenance plan has expired, the customer may purchase an extended

maintenance plan. The maintenance plan and extended maintenance plans will ensure the

customer always has the newest version of Dragon Software. The maintenance plan is critical

to keeping Dragon software updated with the newest capabilities possible, and is critical to the

servicing of the machine. Bend-Tech LLC will contact the Customer regarding updates to the

maintenance plan within 1-month of expiration. Contact Bend-Tech Support to ensure software

Troubleshooting Guide ixBend-Tech Dragon

Customer Service & Satisfaction

Customer Satisfaction Commitment

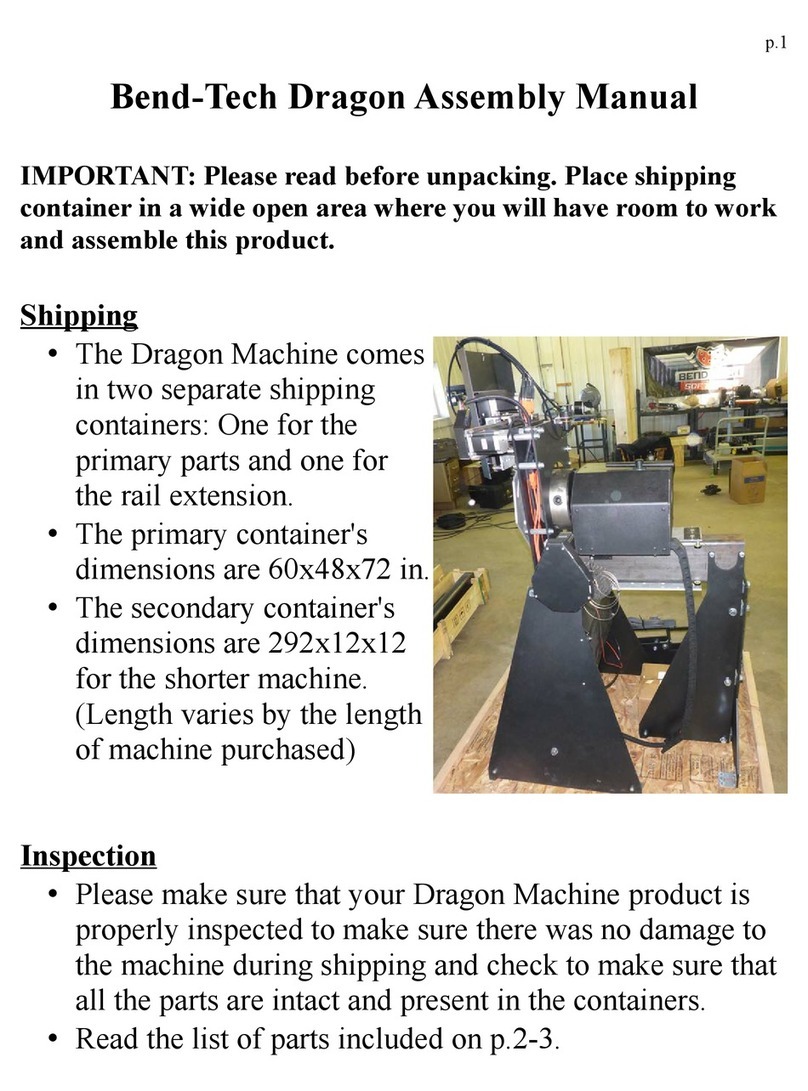

Congratulations on your purchase of the world’s best CNC plasma tube and pipe cutting

machine, the Bend-Tech Dragon. Bend-Tech LLC places great pride in customer satisfaction

our support is a key factor in your success.

Contact Us

Bend-Tech’s hours of operation are Monday - Friday, 8:00 am - 5:00 pm EST. The Bend-Tech

support team and sales team are always available during our hours of operation.

Phone: 651-257-8715

Email: Sales team: [email protected]

Address: Bend-Tech, 729 Prospect Ave., Osceola, WI 54020, U.S.A..

Customer Service

Comments, questions, or concerns regarding the Dragon Machine, this manual, or the Bend-

Tech Software can be directed to Bend-Tech sales and service representatives at the above

contact information. Check out the following links for more information regarding Dragon

Machines and Bend-Tech Software.

Website, Socials, and Online Resources

• http://www.bend-tech.com

• https://www.facebook.com/2020ssi

• https://www.instagram.com/bend_tech

• https://www.youtube.com/bendtech2020

• http://www.bend-tech.com/wiki7

xBend-Tech Dragon

Troubleshooting Guide

Alerts

Alerts

Denitions & Examples

Danger

! Danger !

Danger indicates a serious condition that could cause severe injury or death to the

operator or bystanders if the instructions are not followed.

Warning

! Warning !

A Warning indicates there is a possibility for minor injury if the instructions are not

followed correctly.

Caution

! Caution !

Caution warns the operator that minor injury or machine damage could occur if

instructions are not followed. It could also mean that not following directions could

Troubleshooting Guide xiBend-Tech Dragon

Alerts

Important Alerts

Important

unique to an operation.

Notes and Tips

Note or Tip

Notes and tips give additional helpful information for operating the Dragon machine or Dragon

software. They are meant for supplemental information and not information that is critical for

operating procedures.

xii Bend-Tech Dragon

Troubleshooting Guide

Glossary

Glossary

Axis

Beak

The front assembly that includes the

Parts Catcher and Parts Bin/Bucket.

The Material Coolant System replaces

most of the Beak when installed.

CAD

Computer Aided Design. Modeling or design

software for creating parts, components, or

whole assemblies. Used for manufacturing or

similar industries. Can be 2D or 3D design.

CAM

Computer Aided Manufacturing or Machining.

Using the computer to assist in operating

machines by converting CAD models into

G-Code that the machine recognizes.

Chuck

Secures and rotates the material. Part of

the Trolley. Also referred to as the Y-Axis.

Control Box

Contains the motor drivers and other electrical

components that allows the Dragon CAM

software to control the Dragon machines.

Deadzone

The space between the Chuck and

the Laser Light position when the

Chuck is all the way forward.

Emergency Stop

Abbreviated E-STOP. A button which shuts down

machine operations. Four are located on the

machine and one is part of Machine Control.

Gate

The adjustable mechanism that holds the

material in place at the Head of the Machine.

Head

The machine assembly that makes

up the front end of the machine.

Limit Switch

The switch that operates as an automatic

control to prevent a mechanism or process

from going beyond a prescribed limit.

Load Position

The position the machine enters after

time after starting a cutting project. This

allows the operator to more easily load the

designated material into the machine.

Mach3

The driving software behind Machine Control.

Required for the machine to operate.

Machine Control

The computer interface that controls

the machine operations. Used by the

operator when running projects.

Material Coolant System

The system that transports coolant through

the material during cutting operations.

Material Support Lift

The mechanism that supports the

material during cutting. Sometimes

referred to as the Lifter.

Parts Catcher

The Parts Catcher is placed at the front of

the machine to catch parts as they are cut.

Support Beam

Forms the backbone of the machine. Comprised

of Aluminum Beams and Steel Rails.

Tail

The machine assembly that makes

up the far end of the machine.

Troubleshooting Guide xiiiBend-Tech Dragon

Glossary

Task Menu

the Dragon Software or the Bend-Tech

software. From this menu various tasks

can be started, such as part designing,

importing, library access, etc.

Toolhead

The machine component that the tools

are attached too. Maneuvers the tools

into position with the A and Z axes.

Trolley

The machine component that

includes the Chuck. Travels along the

Support Beam on the X-Axis.

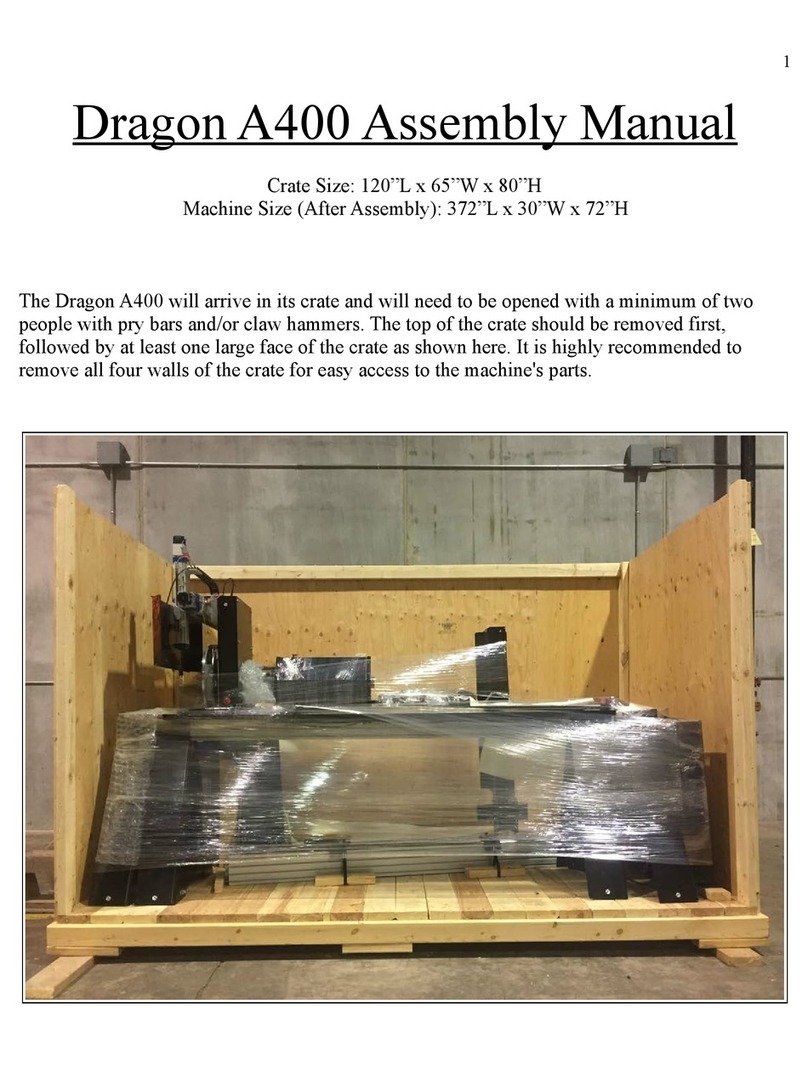

Beak

Control Box

Toolhead

Chuck

Material

Support Lift

Support Beam

Tail

Trolley

Gate

Head

Dragon A400

Dragon A250

xiv Bend-Tech Dragon

Troubleshooting Guide

Machine Capabilities

Machine Capabilities

Material Types

Steel Stainless Steel Galvanized Steel Aluminum Black Pipe Chrome Alloy

Max Material Weight

Round RectangleSquare Angle/Channel

Max: 6”

(152.4mm)

Min: .75”

(19mm)

Max: 4”

(101.6mm)

Min: 1”

(25.4mm)

Max: 4”

(101.6mm)

Min: 1”

(25.4mm)

Max: 4”

(101.6mm)

Min: 1”

(25.4mm)

400 lbs

(181.4kg)

5/8”

(15.8mm)

1/32”

(0.79mm)

Material Size

Material Thickness

*Can process rectangle tubes up to a

6.375” hypotenuse. (e.g. 2”x6”, 3”x5”)

Material Size

Round RectangleSquare

Max: 6”

(152.4mm)

Min: .75”

(19mm)

Max: 4”

(101.6mm)

Min: 1”

(25.4mm)

Max: 4”

(101.6mm)

Min: 1”

(25.4mm)

Max: 4”

(101.6mm)

Min: 1”

(25.4mm)

400 lbs

(181.4kg)

5/8”

(15.8mm)

1/32”

(0.79mm)

*Can process rectangle tubes up to a

6.375” hypotenuse. (e.g. 2”x6”, 3”x5”)

Max Material Weight

Material Thickness

Material Size

Round

Max Material Weight

Material Thickness

Dragon A400 with Powered Gate

Dragon A250

Dragon A400

15Bend-Tech Dragon

Troubleshooting

01

Troubleshooting Guide

01

Troubleshooting

1.1 How to Send a Support Session

Properly setting up a Support Session with a Bend-Tech Service Technician can be key to

keeping the Dragon up and running.

1. Open the Part Design or Nesting Project

sending a Support Session, then keep the project open after submitting.

2. Open the Support Session

On the Bend-Tech Dragon Home interface, click the Help tab, then click Support Request.

3. Fill in the requested information

Fill in your Name, E-mail, Phone Number, and if you know a Service Technician or have had

4. Provide Details about the Problem

Give a detailed description of the issue in the Description of Problem text box. The more

information given the better our Service Technicians can help.

5. Attach the Files

6. Submit the Session

Click Submit.

16 Bend-Tech Dragon

Gate Troubleshooting

02

Troubleshooting Guide

02

Gate Troubleshooting

2.1 Dragon Gate Troubleshooting

2.1.1 Eccentric bearing on the Gate is sticking

Bearings are Dirty

Clean the bearings with compressed air, brake cleaner, or glass cleaner.

2.1.2 Gate is Binding

Bearings or Bearing Rotation Plate/Gate Ring Gear are Dirty

Clean the Gate using glass cleaner, brake cleaner, or compressed air.

Eccentric Bearing needs Adjustment

Remove the Gate and adjust the eccentric bearing on the Bearing Rotation Plate/Gate Ring

Gear. See Section 2.2 for the full procedure.

C-Axis Backlash needs Adjustment

Check the C-Axis for backlash. If play is observed, see Section 2.3.

2.1.3 Gate is Loose

Eccentric Bearing needs Adjustment

Remove the Gate and adjust the eccentric bearing on the Bearing Rotation Plate/Gate Ring

Gear. See Section 2.2 for the full procedure.

17Bend-Tech Dragon

Gate Troubleshooting

02

Troubleshooting Guide

2.1.4 Gate is not Operating Smoothly

Gate is Dirty

Clean the Gate with compressed air, glass cleaner, or brake cleaner. If the Gate is extremely

dirty use a rag or toothbrush to help clean it.

Eccentric Bearing needs Adjustment

Remove the Gate and adjust eccentric bearing on the Bearing Rotation Plate/Gate Ring Gear.

See Section 2.2 for the full procedure.

2.1.5 Play in the Gate

Eccentric Bearing needs Adjustment

Remove the Gate and adjust eccentric bearing on the Bearing Rotation Plate/Gate Ring Gear.

See Section 2.2 for the full procedure.

2.1.6 Gate Jaws are not Operating Smoothly

Lead Screws are Dirty

Clean Gate Lead Screws, with brake cleaner, glass cleaner, or compressed air. Re-lubricate.

Gate Jaw Rack & Pinion are Dirty

Clean Gate Jaw Rack with brake cleaner, glass cleaner, or compressed air.

Important

Customers with older machines who are having this issue should contact

Bend-Tech regarding updating the Gate Lead Screws.

18 Bend-Tech Dragon

Gate Troubleshooting

02

Troubleshooting Guide

2.2 Adjusting the Gate Eccentric Bearing

Tools Needed

•

•

•

•

Extension

•

•

2.2.1 Before Beginning

Power on the Dragon machine, and move the Toolhead up for easy access to the Gate.

Though the procedure for adjusting the Gate Eccentric Bearing is the same for both the

Powered Gate and Non-Powered Gate, there are a few additional steps when uninstalling and

installing the Powered Gate. For Non-Powered Gates, skip to 2.2.4.

Note

The Parts Catcher, Beak Assembly, and/or Coolant Trays may need to be removed before

uninstalling the Gate from the Dragon

2.2.2 Remove Safety Guards (Powered Gate Only)

The safety guards are only installed on machines

with Powered Gates. Locate the Gate Ring Gear

Safety Guards on the right and left sides of the

Powered Gate.

in. wrench on the nut and remove the screws

19Bend-Tech Dragon

Gate Troubleshooting

02

Troubleshooting Guide

2.2.3 Remove the Drive Gear (Powered Gate Only)

Turn the position of the C-Axis Drive Gear so that the

set screws are visible. Remove each set screw with a

2.2.4 Remove the Gate

Four bolts secure the Gate Assembly to the Dragon.

On a Powered Gate machine. There are four access

holes in the Gate Ring Gear which allows access to

the Gate Mount Bolts. Turn the Gate Ring Gear to

access the Gate Mount Bolts.

Locate the four Gate Mount Bolts and loosen them

enlisting a helper, remove the Gate from the front of

the machine. Place it on the work surface face down.

2.2.5 Adjust the Eccentric Bearing

There are two concentric bearings, which are not

adjustable and one eccentric bearing that is. When the

eccentric gear is properly adjusted, there should be no

play between the gate mount plate and the gate ring.

Use a ratchet and 17mm socket to loosen the eccentric

bearing enough that it can be rotated for adjustment.

20 Bend-Tech Dragon

Gate Troubleshooting

02

Troubleshooting Guide

Place the supplied ¾ in. thin wrench on the eccentric bearing adjustment hex located between

the Gate Mount Plate and the Gate Bearing Rotation Plate or Gate Ring Gear. Turn the

adjustment hex until the Gate Ring Gear bearing surface is fully seated in the eccentric bearing

v-groove.

When properly adjusted, the Gate Ring Gear should spin freely with no side play. Tighten the

v-groove eccentric bearing nut securely, ensuring the bearing stays in adjustment.

2.2.6 Re-install the Gate

Re-install the Gate. Use assistance in placing the gate. Ensure the eccentric bearing is to the

Important

Re-install the Parts Catcher, Beak, and/or Coolant Trays if they were removed to

access the Gate.

2.2.8 Position Drive Gear (Powered Gate Only)

Push the C-Axis Drive Gear onto the C-Axis motor shaft. Ensure it fully meshes at the center of

the Gate Ring Gear. The drive gear must be centered on the Gate Ring Gear.

2.2.9 Re-attach the Safety Guards (Powered Gate Only)

Re-install the Safety Guards.

2.3 Adjusting the C-Axis Backlash

Adjusting the C-Axis Backlash is only necessary on Dragon A400 machines equipped with a

Powered Gate.

1. Remove the Safety Guard

Motor Mount. Set the screws and guard aside.

2. Loosen the C-Axis Motor Mount

Other manuals for Dragon mAchines

1

Table of contents

Other Bend-Tech Industrial Equipment manuals

Bend-Tech

Bend-Tech Dragon A400 Installation guide

Bend-Tech

Bend-Tech DRAGON A150 User manual

Bend-Tech

Bend-Tech Dragon A400 User manual

Bend-Tech

Bend-Tech Dragon A400 User manual

Bend-Tech

Bend-Tech Dragon User manual

Bend-Tech

Bend-Tech Dragon A400 User manual

Bend-Tech

Bend-Tech Dragon A400 Installation guide

Bend-Tech

Bend-Tech Dragon A400 Installation and operation manual

Bend-Tech

Bend-Tech Dragon A400 User manual

Bend-Tech

Bend-Tech Dragon mAchines User manual