Volumetric Dough Divider Calybra - Calybra L

2/59

Usage and Maintenance Manual (Translation of the original instructions) –MASV7_en_0 dated 01/09/2016

TABLE OF CONTENTS

CE DECLARATION OF CONFORMITY........................................................................................................................................................................... 4

1INTRODUCTION...................................................................................................................................................................................................... 5

1.1 PREAMBLE....................................................................................................................................................................................5

1.2 INSTRUCTIONS AND GENERAL WARNINGS..............................................................................................................................6

1.3 MAIN CASES IN WHICH THE COMPANY DECLINES ANY AND ALL LIABILITY.........................................................................6

1.4 TERMINOLOGY.............................................................................................................................................................................7

1.5 VALIDITy of the ce marking and of the ce declaration of conformity...............................................................................................7

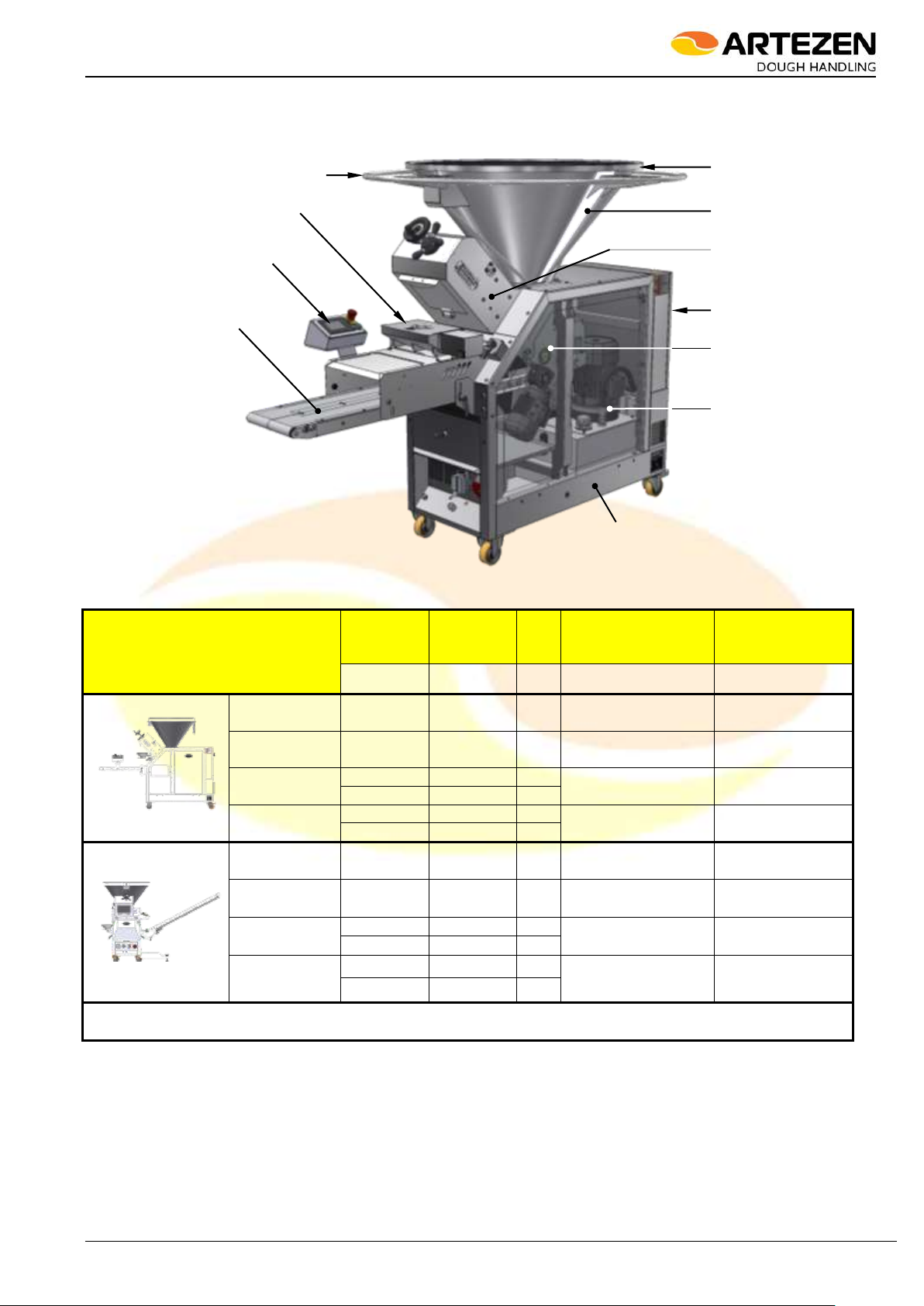

2CHARACTERISTICS OF THE MACHINE............................................................................................................................................................ 8

2.1 DESCRIPTION AND INTENDED USE...........................................................................................................................................8

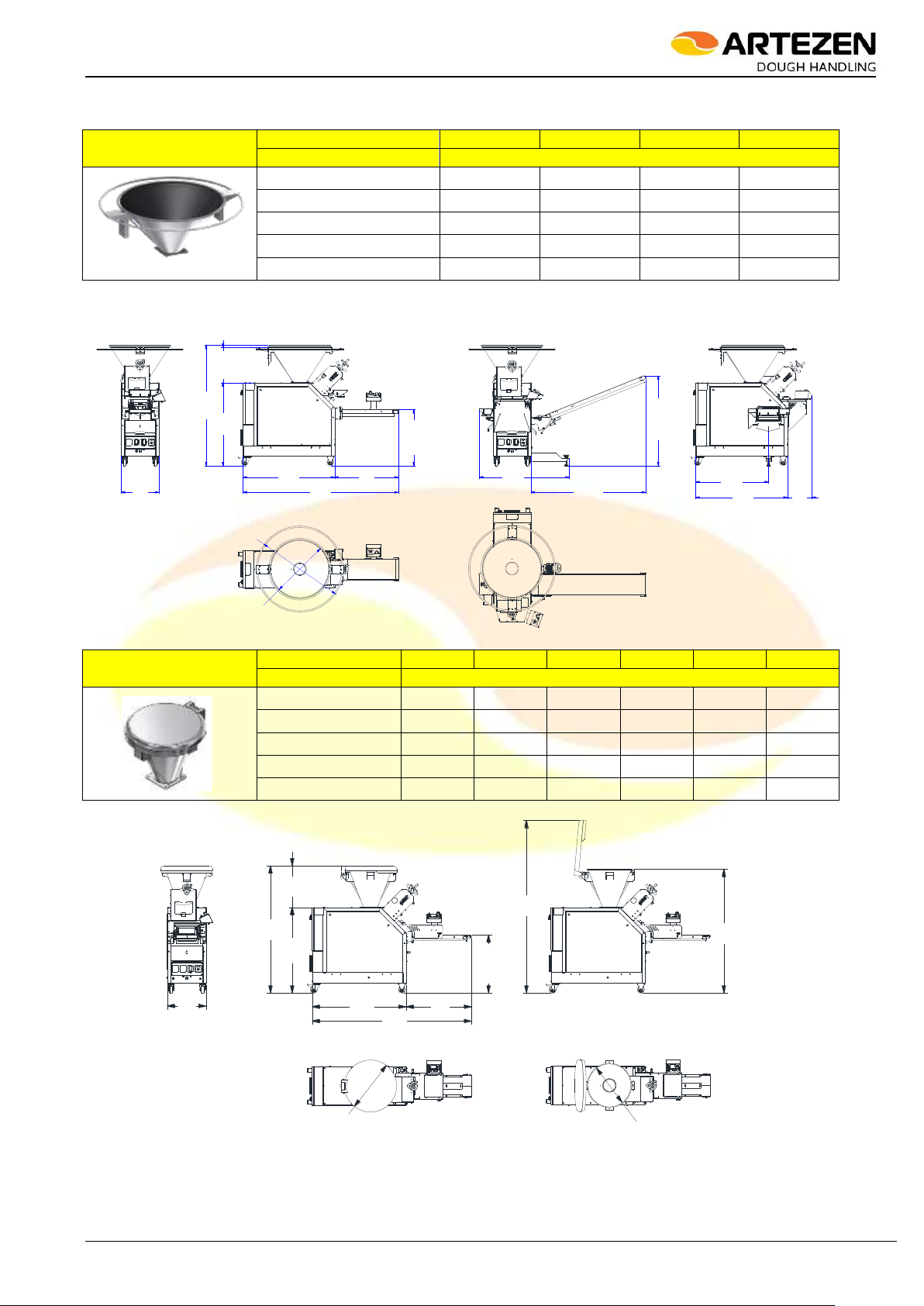

2.2 MODELS, VERSIONS AND CHARACTERISTICS OF THE MACHINE..........................................................................................9

2.3 MAIN SWITCH.............................................................................................................................................................................12

2.4 CONTROL PANEL.......................................................................................................................................................................12

2.4.1 ELECTRO-MECHANICAL CONTROL PANEL ..................................................................................................................................... 12

2.4.2 “TOUCH SCREEN” CONTROL PANEL ................................................................................................................................................. 13

2.4.3 “MEMORY PACK” CONTROL PANEL ................................................................................................................................................... 14

2.4.4 «V» BELT RELATIVE SPEED CONTROL DEVICE............................................................................................................................. 14

2.5 IDENTIFICATION PLATE.............................................................................................................................................................15

3INSTALLATION AND USE................................................................................................................................................................................... 15

3.1 INSTALLATION SITE REQUIREMENTS .....................................................................................................................................15

3.2 TRANSPORT, HANDLING AND POSITIONING ..........................................................................................................................16

3.3 ASSEMBLING/DISSASEMBLING THE SPACER RING...............................................................................................................17

3.4 ASSEMBLY/DISASSEMBLY OF THE FLOUR DUSTER.............................................................................................................21

3.5 ASSEMBLY/DISASSEMBLY OF THE V-BELTS (CALYBRA L - VERSION “INTERNAL V-BELT”) ..............................................22

3.6 ELECTRICAL HOOK-UP..............................................................................................................................................................24

3.7 (HOUSING FOR) AUXILIARY CONNECTION DEVICES.............................................................................................................24

3.8 FIRST START-UP AND CONTROL OF CORRECT MOTOR ROTATION DIRECTION................................................................25

3.9 OPERATION AND USE ...............................................................................................................................................................25

3.9.1 GENERAL INFORMATION OF NORMAL USE.................................................................................................................................... 25

3.9.2 STARTING UP THE MACHINE............................................................................................................................................................... 26

3.9.3 HOW TO USE THE MACHINE................................................................................................................................................................ 27

3.9.4 EMPTYING THE MACHINE..................................................................................................................................................................... 30

3.9.5 POSSIBLE METHODS OF STOPPING AND RESTARTING THE MACHINE................................................................................. 30

3.10 REGULATING THE INCLINATION OF THE PRODUCT OUTPUT BELT.....................................................................................31

3.11 INSTRUCTION AND TRAINING OF THE MACHINE OPERATORS............................................................................................32

4MAINTENANCE..................................................................................................................................................................................................... 33

4.1 INTRODUCTION..........................................................................................................................................................................33

4.2 ROUTINE AND PROGRAMMED MAINTENANCE.......................................................................................................................33

4.3 HYDRAULIC CIRCUIT .................................................................................................................................................................33

4.3.1 FILLING AND/OR REPLACING OIL IN THE HYDRAULIC BLOCK .................................................................................................. 33

4.3.2 OIL TEMPERATURE CONTROL SENSOR.......................................................................................................................................... 35

4.3.3 REPLACING HOSES (extraordinary/routine maintenance) ................................................................................................................ 35

4.4 ROUTINE CLEANING OF THE MACHINE...................................................................................................................................35

4.4.1 CLEANING THE WEIGHT CHAMBER .................................................................................................................................................. 36

4.4.2 CLEANING THE HOPPER....................................................................................................................................................................... 37

4.4.3 CLEANING THE BELTS........................................................................................................................................................................... 37

4.4.4 CLEANING THE HYDRAULIC BLOCK AND THE HEAT EXCHANGER.......................................................................................... 38

4.4.5 CLEANING THE DUST AND RESIDUE COLLECTION DRAWERS................................................................................................. 39

4.4.6 CLEANING THE BELT SCRAPER (OPTIONAL) ................................................................................................................................. 39

4.4.7 CLEANING THE FLOUR DUSTER......................................................................................................................................................... 40

4.5 ELECTRICAL MAINTENANCE ....................................................................................................................................................40

4.7 REPLACING THE MICRO-SWITCHES ASSOCIATED WITH THE HOPPER COVER ................................................................42

4.8 REPLACING THE MICRO-SWITCHES ASSOCIATED WITH THE WEIGHT CHAMBER DOOR ................................................43

4.9 REPLACEMENT PARTS..............................................................................................................................................................46

4.10 PROLONGED SHUT-DOWN OR EXCLUSION FROM SERVICE................................................................................................46

4.11 POTENTIAL BREAKDOWNS AND/OR ANOMALIES ..................................................................................................................46

4.12 DIAGNOSTIC SIGNALS - ALARMS.............................................................................................................................................50

5SAFETY................................................................................................................................................................................................................... 52

5.1 INTRODUCTION..........................................................................................................................................................................52

5.2 DANGERS, SAFETY DEVICES AND RESIDUAL RISKS ............................................................................................................52

5.2.1 DANGERS TYPICAL OF THIS MACHINE ............................................................................................................................................ 52

5.2.2 SAFETY EQUIPMENT OF THIS MACHINE.......................................................................................................................................... 53

5.2.3 CONTROLLING THE EFFICIENCY OF THE SAFETY EQUIPMENT............................................................................................... 54

5.3 RESIDUAL RISKS........................................................................................................................................................................56

5.3.1 MECHANICAL RESIDUAL RISKS.......................................................................................................................................................... 56

5.3.2 RESIDUAL RISKS DUE TO HYDRAULIC PRESSURE...................................................................................................................... 56

5.3.3 RESIDUAL RISKS DUE TO DUST INHALATION................................................................................................................................ 56

5.3.4 RESIDUAL RISKS DUE TO LACK OF HYGIENE................................................................................................................................ 57

5.3.5 RESIDUAL RISKS DUE TO BREACH OF ERGONOMIC PRINCIPLES.......................................................................................... 57

5.3.6 RESIDUAL HEALTH RISKS DUE TO CONTACT WITH OIL............................................................................................................. 57

5.3.7 ELECTRICAL RESIDUAL RISKS ........................................................................................................................................................... 57

5.3.8 RISK OF POLLUTING THE ENVIRONMENT (GROUND).................................................................................................................. 58