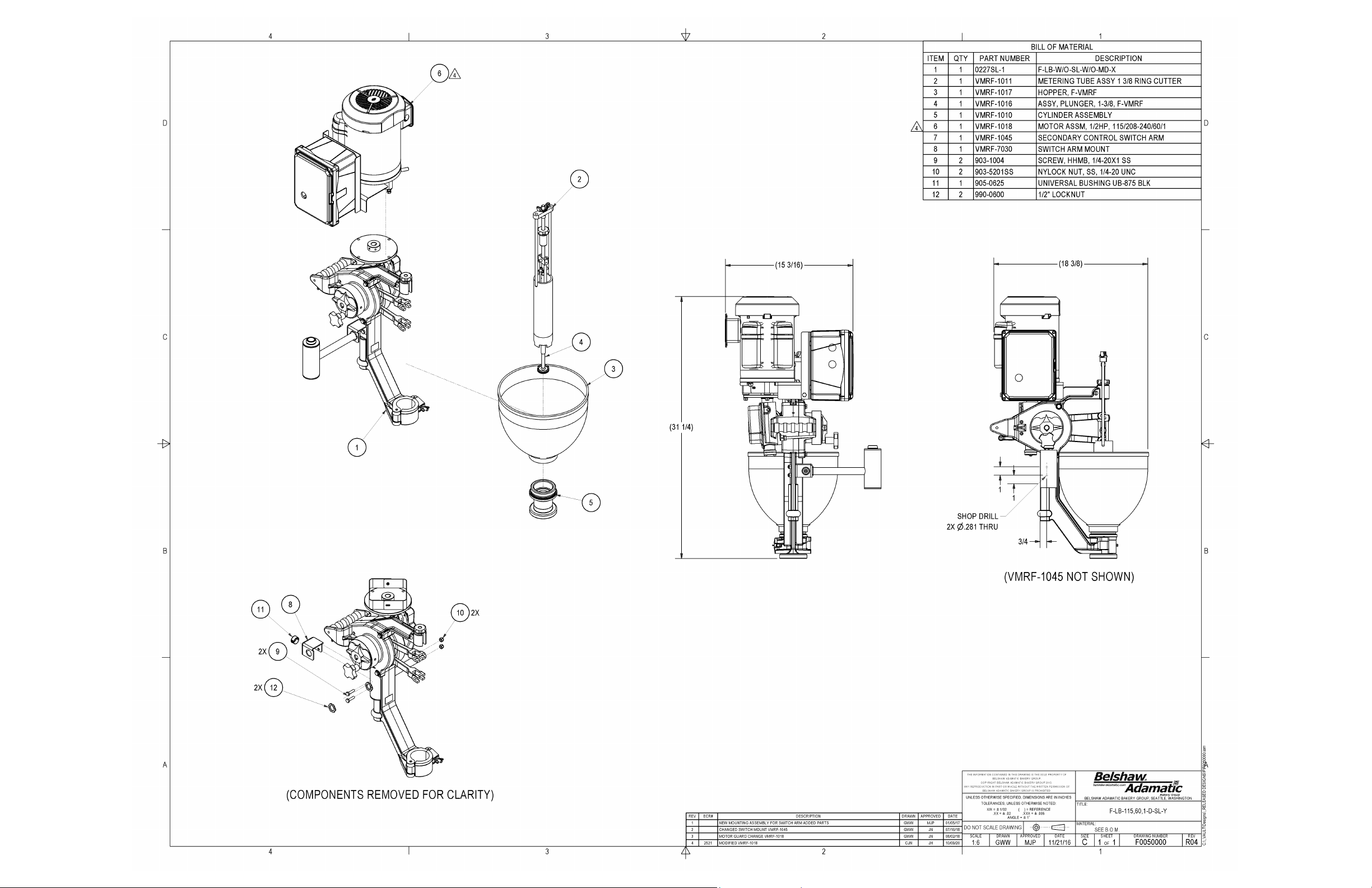

Belshaw Brothers F-YRD F0050000 User manual

This manual suits for next models

1

Other Belshaw Brothers Commercial Food Equipment manuals

Belshaw Brothers

Belshaw Brothers SF18 User manual

Belshaw Brothers

Belshaw Brothers HG18EZ User manual

Belshaw Brothers

Belshaw Brothers T User manual

Belshaw Brothers

Belshaw Brothers Type K Operation manual

Belshaw Brothers

Belshaw Brothers H&I-2 Operation manual

Belshaw Brothers

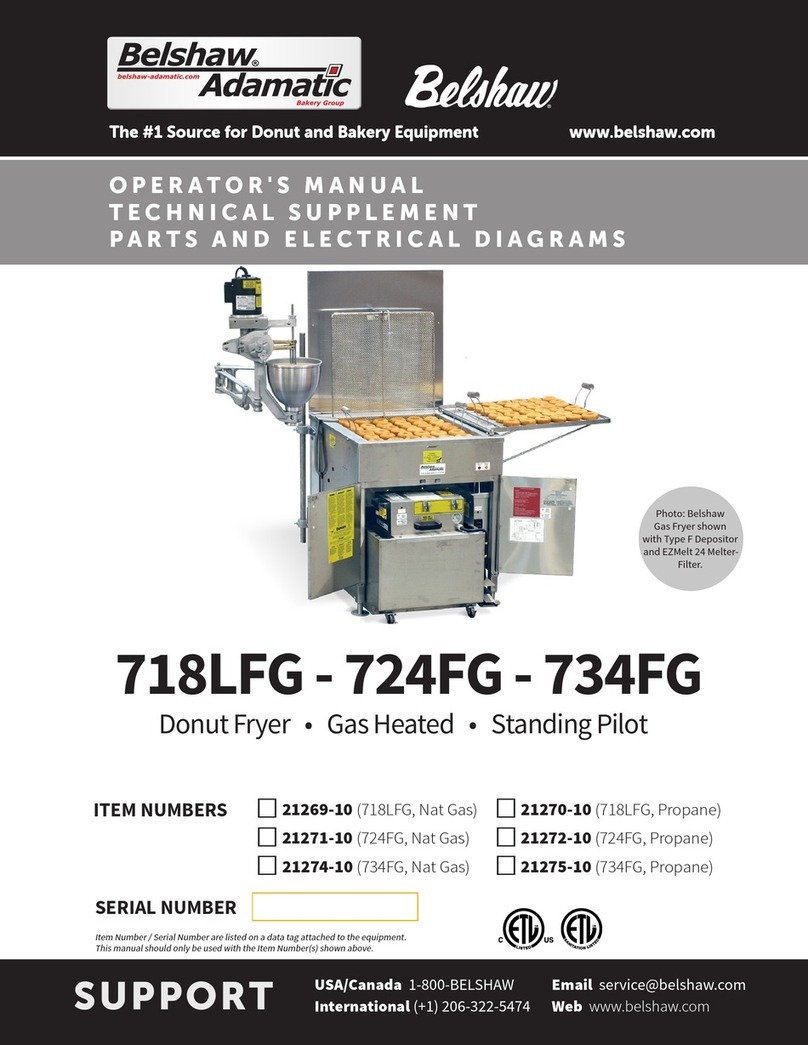

Belshaw Brothers 718LFG User manual

Belshaw Brothers

Belshaw Brothers TG 50 User manual

Belshaw Brothers

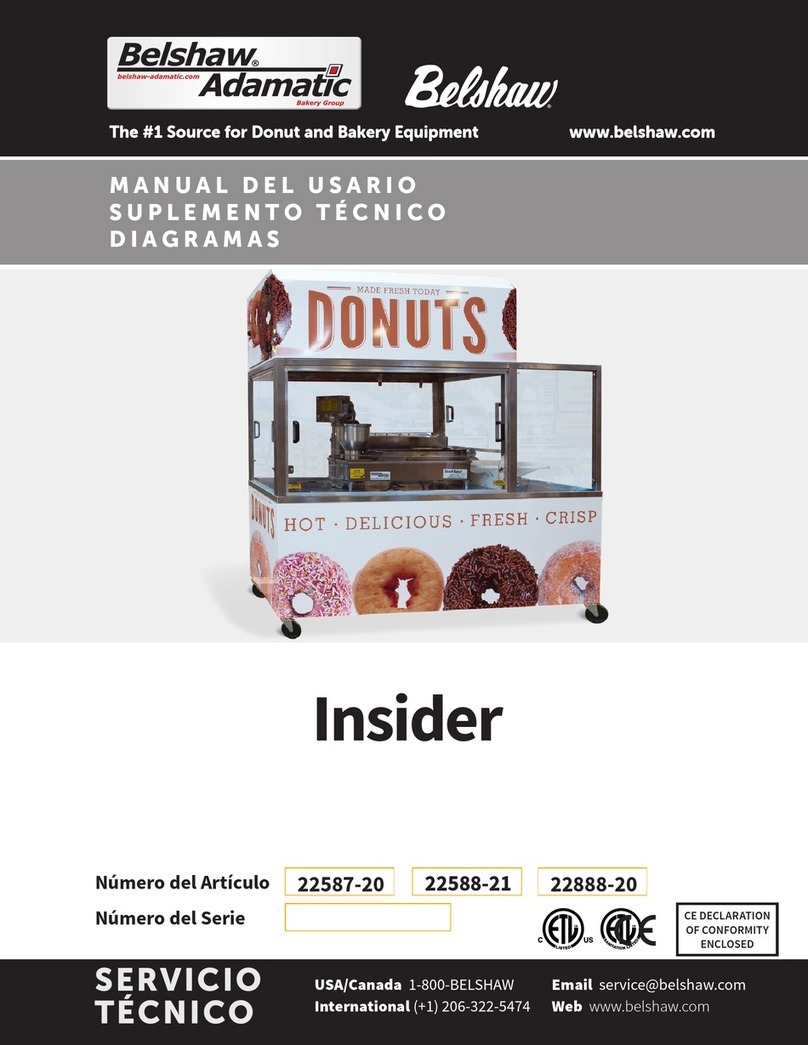

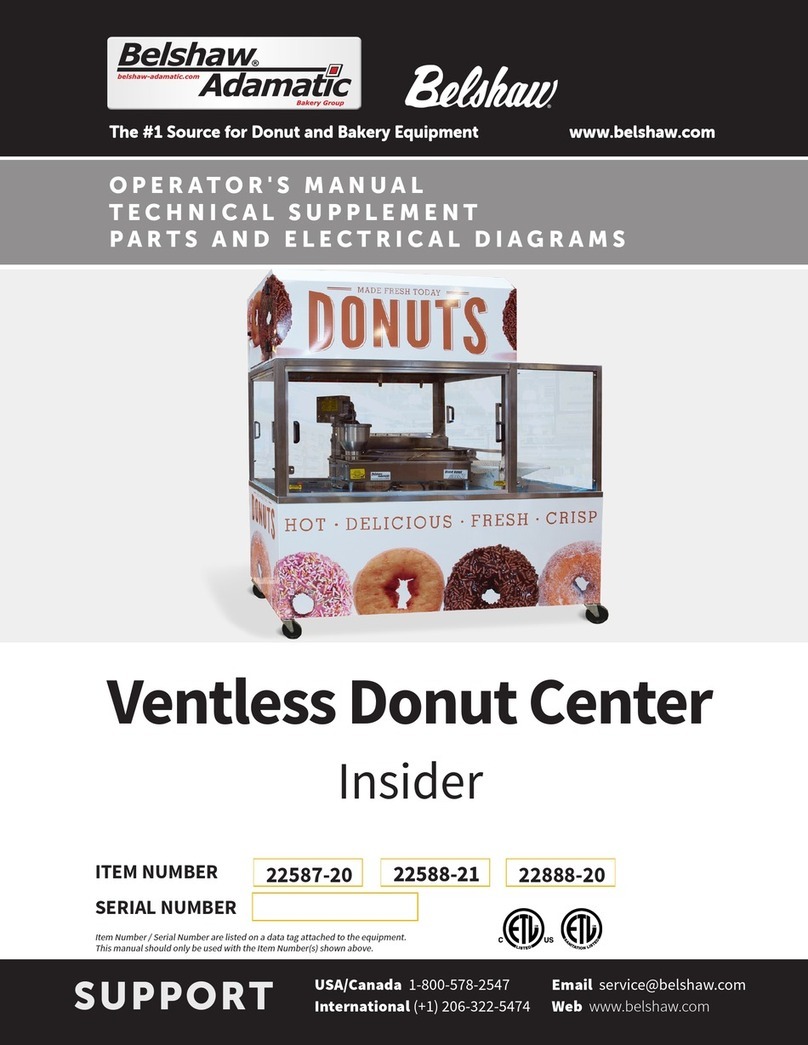

Belshaw Brothers 22587-20 User manual

Belshaw Brothers

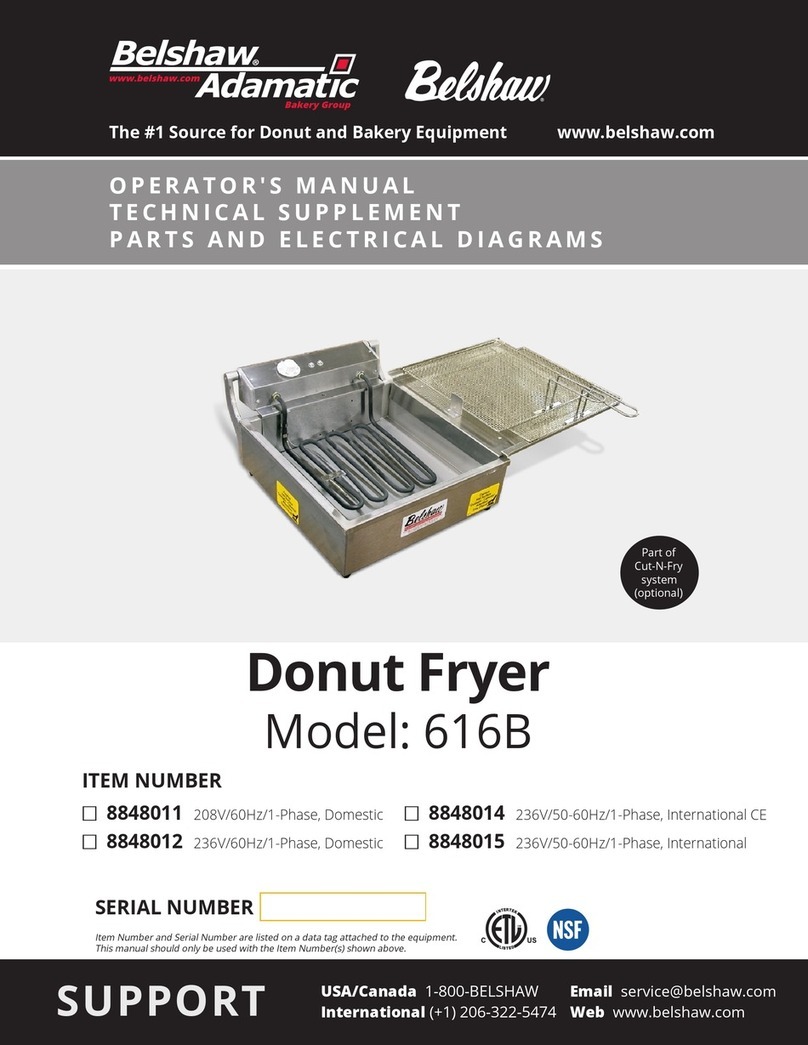

Belshaw Brothers 616B User manual

Belshaw Brothers

Belshaw Brothers Donut Robot Mark II User manual

Belshaw Brothers

Belshaw Brothers H18F User manual

Belshaw Brothers

Belshaw Brothers EZMelt 18 User manual

Belshaw Brothers

Belshaw Brothers 22587-20 User manual

Belshaw Brothers

Belshaw Brothers TZ6 User manual

Belshaw Brothers

Belshaw Brothers B00010001 User manual

Belshaw Brothers

Belshaw Brothers Donut Robot Mark II User manual

Belshaw Brothers

Belshaw Brothers Heat & Ice H&I-2 User manual

Belshaw Brothers

Belshaw Brothers Donut Robot Mark VI User manual

Belshaw Brothers

Belshaw Brothers Donut Robot Mark II User manual

Belshaw Brothers

Belshaw Brothers Adamatic HI18F User manual

Popular Commercial Food Equipment manuals by other brands

McDonald's

McDonald's C602 Planned Maintenance Manual

Marshall Amplification

Marshall Amplification DH1-1010 Series owner's manual

Nordcap

Nordcap CSD011E manual

B+S

B+S TF Series Installation, operating and servicing instruction manual

edenox

edenox VCA-PV-EC-311 Manual instruction

Omcan

Omcan CE-CN-0356 instruction manual