1

TABLEOFCONTENTS

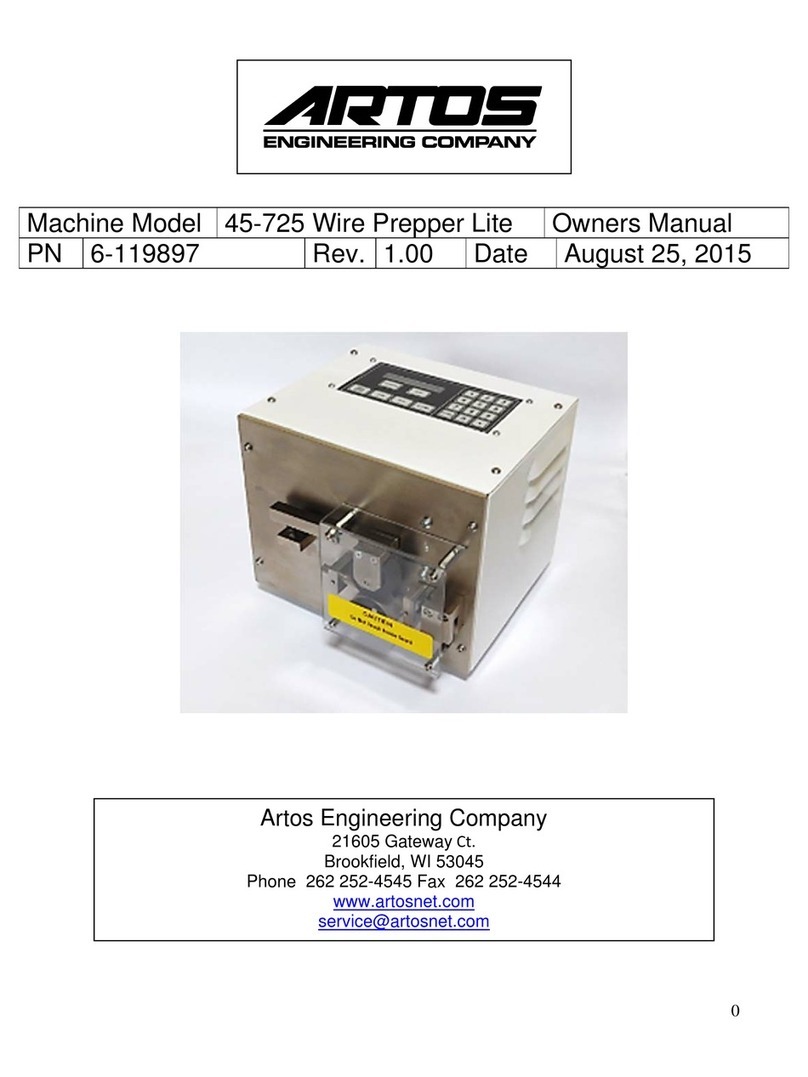

CustomerSafetyNotice..................................................................................................................2

LimitsofUse....................................................................................................................................2

Introduction....................................................................................................................................2

Unpacking.......................................................................................................................................2

OperatorControlFeatures..............................................................................................................3

ON‐OFFSwitch............................................................................................................................3

ControlButtons...........................................................................................................................3

StandardFeatures...........................................................................................................................3

Set‐up..............................................................................................................................................4

PuttingtheMachinetoWork.........................................................................................................4

OperatingInstructions....................................................................................................................5

ChangingProgramSettings.............................................................................................................6

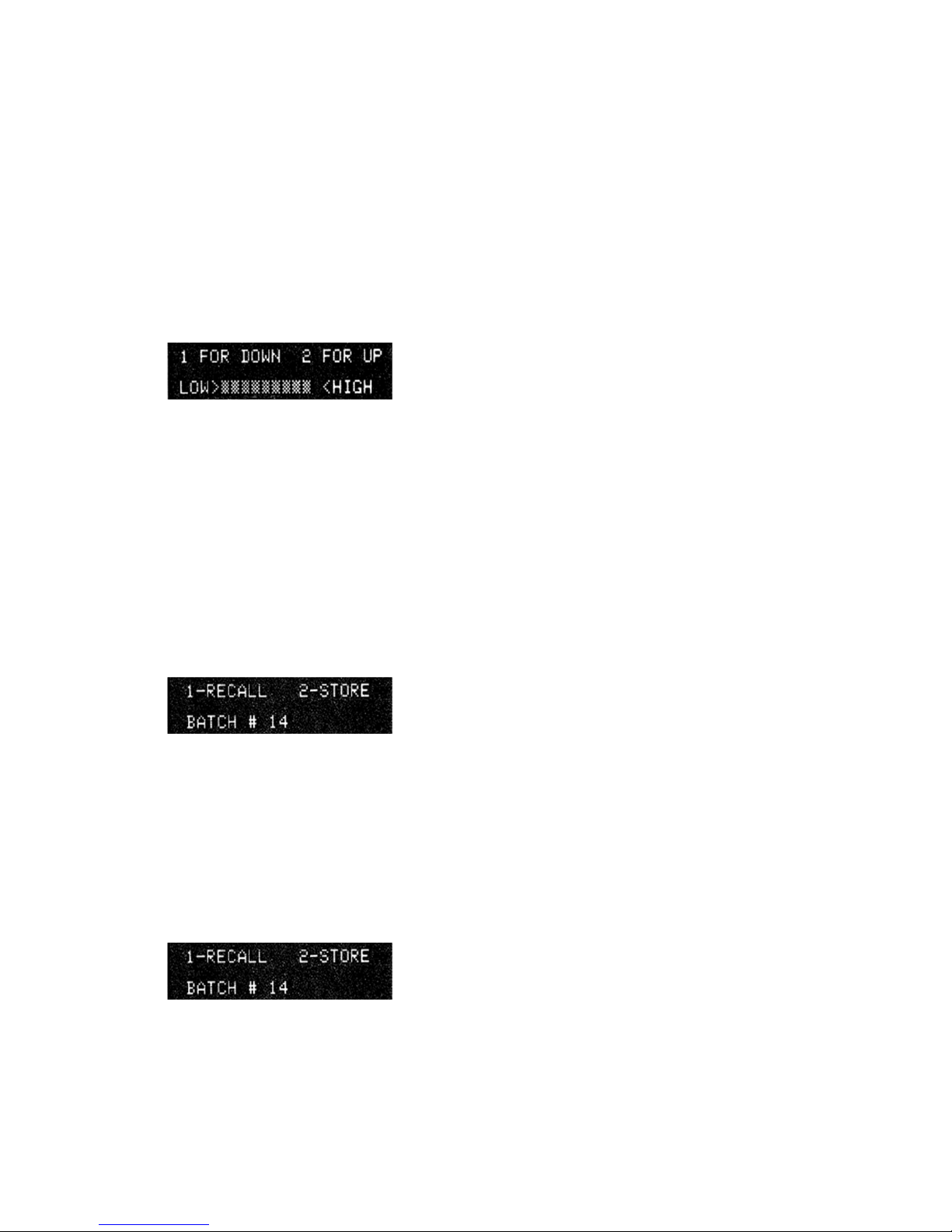

WireDriveSpeed:.......................................................................................................................6

StoringWireBatches:.................................................................................................................6

RecallWireBatches:...................................................................................................................6

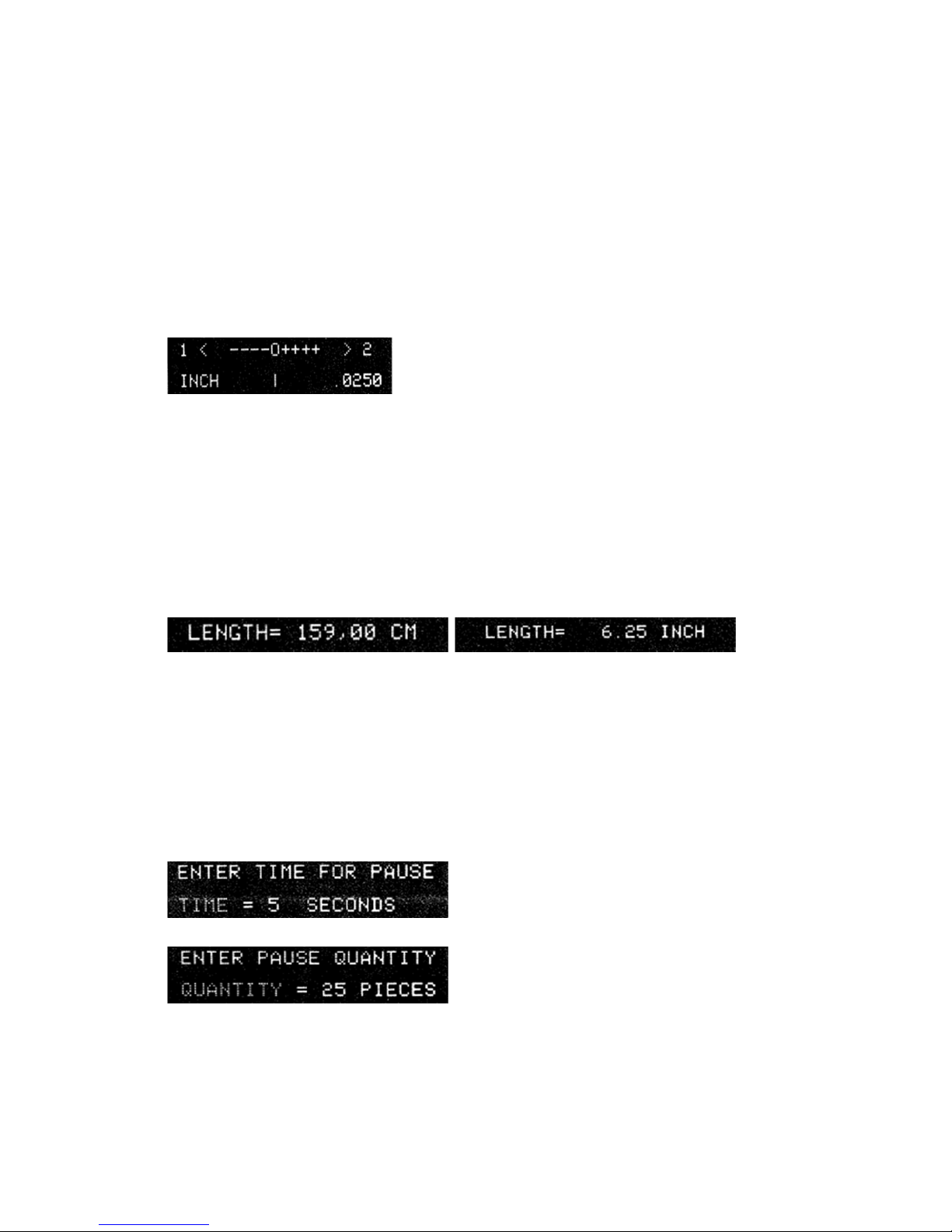

WireLengthCalibration:.............................................................................................................6

ChangingMode:..........................................................................................................................7

ActivatePauseMode:.................................................................................................................7

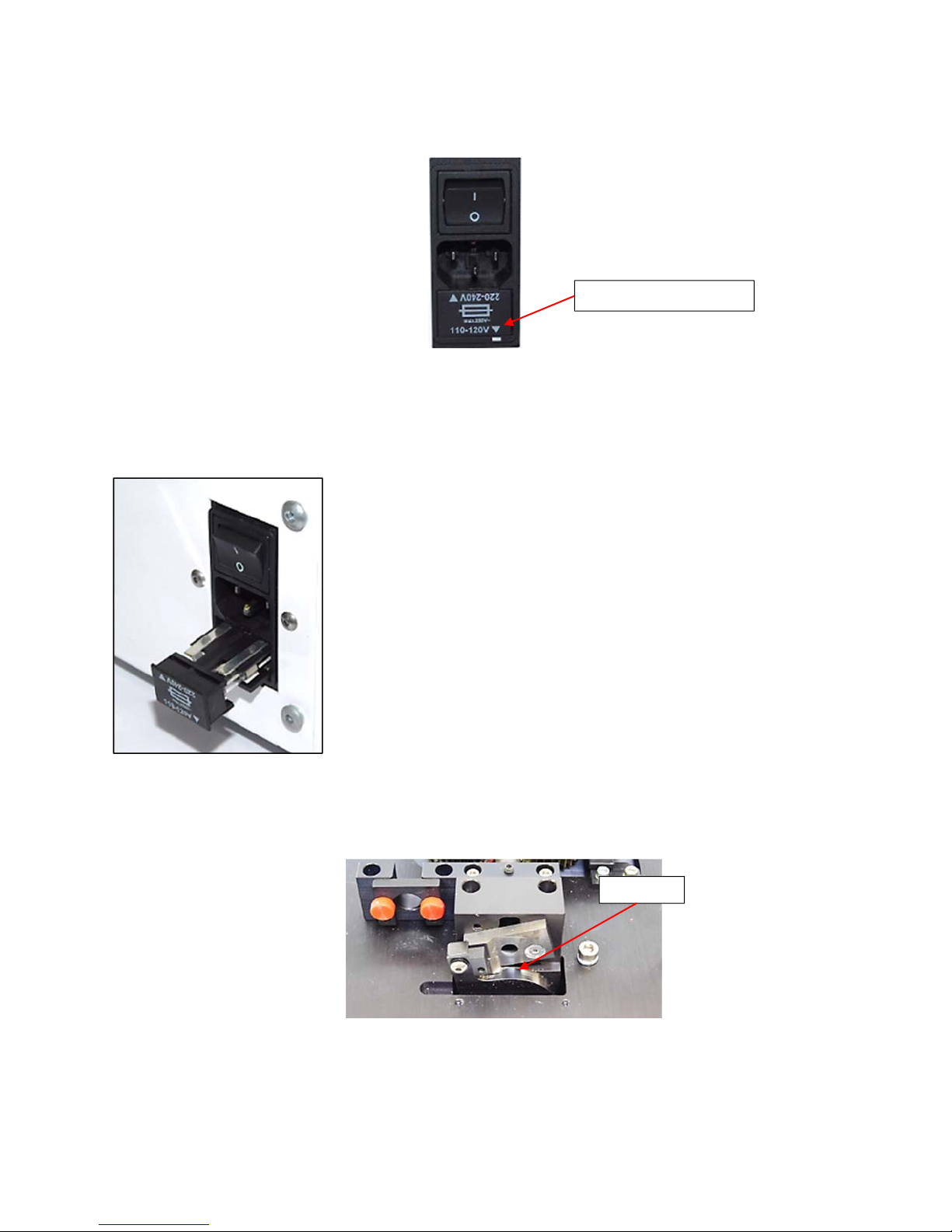

VoltageSelection............................................................................................................................7

FuseReplacement...........................................................................................................................8

Maintenance...................................................................................................................................8

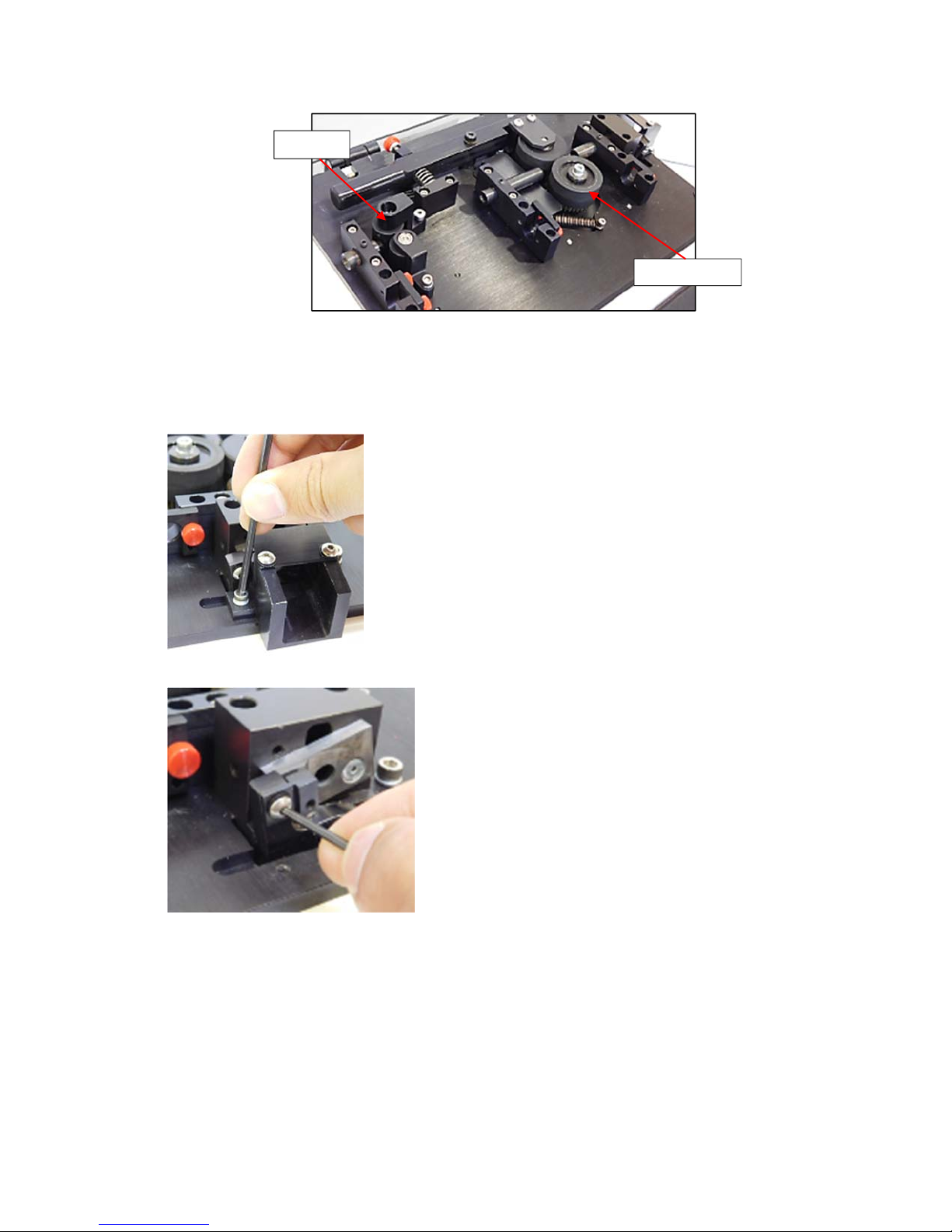

BladeReplacement.........................................................................................................................9

EncoderDisassembly....................................................................................................................10

EncoderAssembly.........................................................................................................................13

DriveWheelReplacement............................................................................................................14

TroubleShooting...........................................................................................................................16

“WireAlarm”Sounds................................................................................................................16

WireLengthNotAccurate........................................................................................................16

DisplayReads“CalculatingCalRegisters”................................................................................16

DisplayReads“CutterMalfunction,MachineWillNotCut”....................................................17

MachineWillNotFunction,AllSwitchesDoNotWork............................................................17

CuttersCyclesContinuously.....................................................................................................17

DriveWheelOperationisRough..............................................................................................17

CuttersDoNotCutMaterialCleanly........................................................................................18

WireandTubingCutsareNotSquare......................................................................................18

TubingCrushedbyRollers........................................................................................................18

Accessories....................................................................................................................................19