-Keep proper footing and balance at all times. You may tumble and get hurt.

-Do not operate the machine when you cannot concentrate on your work, e.g. when

you are tired or while under the inuence of alcohol, medication or drugs.

Otherwise, accident or injury may occur.

-Before turning on the machine, make sure that hand tools used for inspection or

adjustment are removed from the machine. Accident or injury may occur if you

start the machine with hand tools on it.

-Use only the accessories and attachments given in this manual and our catalogs.

A failure to do so will lead to accident or injury.

-Immediately stop the machine if something is wrong with the machine or you have

noticed unusual smell, vibration, sound, etc. during operation, and refer to

"5.TROUBLE SHOOTING" in this manual and follow the corresponding instructions.

-Repair should only be carried out by our sales representative. Otherwise the

machine may not show its performance or you may get injured. Ask the shop of

your purchase or our sales ofce.

-Our products are in accordance with the relevant safety rules. Do not modify them.

-Do not put the machine or workpiece on the Power Cord. Damaged cord and

current leakage will occur.

-Watch the position of your nger while lowering frame to avoid pinching of ngers.

-Do not leave the machine with a long workpiece set on it. You may tumble and get

hurt.

-Securely install accessories in accordance with this manual. Otherwise, accident

or injury result.

-Before further use of the machine that is damaged should be carefully checked to

determine that it will operate properly and perform its intended function.

-If you have dropped or hit the machine accidentally, carefully check for damage,

crack or deformation. If the machine is used with such defect, poor cutting

accuracy, accident and injury can result.

-Before leaving the machine for a long time, disconnect the Power Plug.

-The work material with chip is slippery. Do not drop it on your feet.

-Keep your work bench and area tidy and well lit. Cluttered areas and benches

invite injuries.

-Do not let visitors touch the machine and Power Cord or operate the machine.

-When not in use, machines should be stored in dry and high or locked up place -

out of reach of children.

CONTENTS

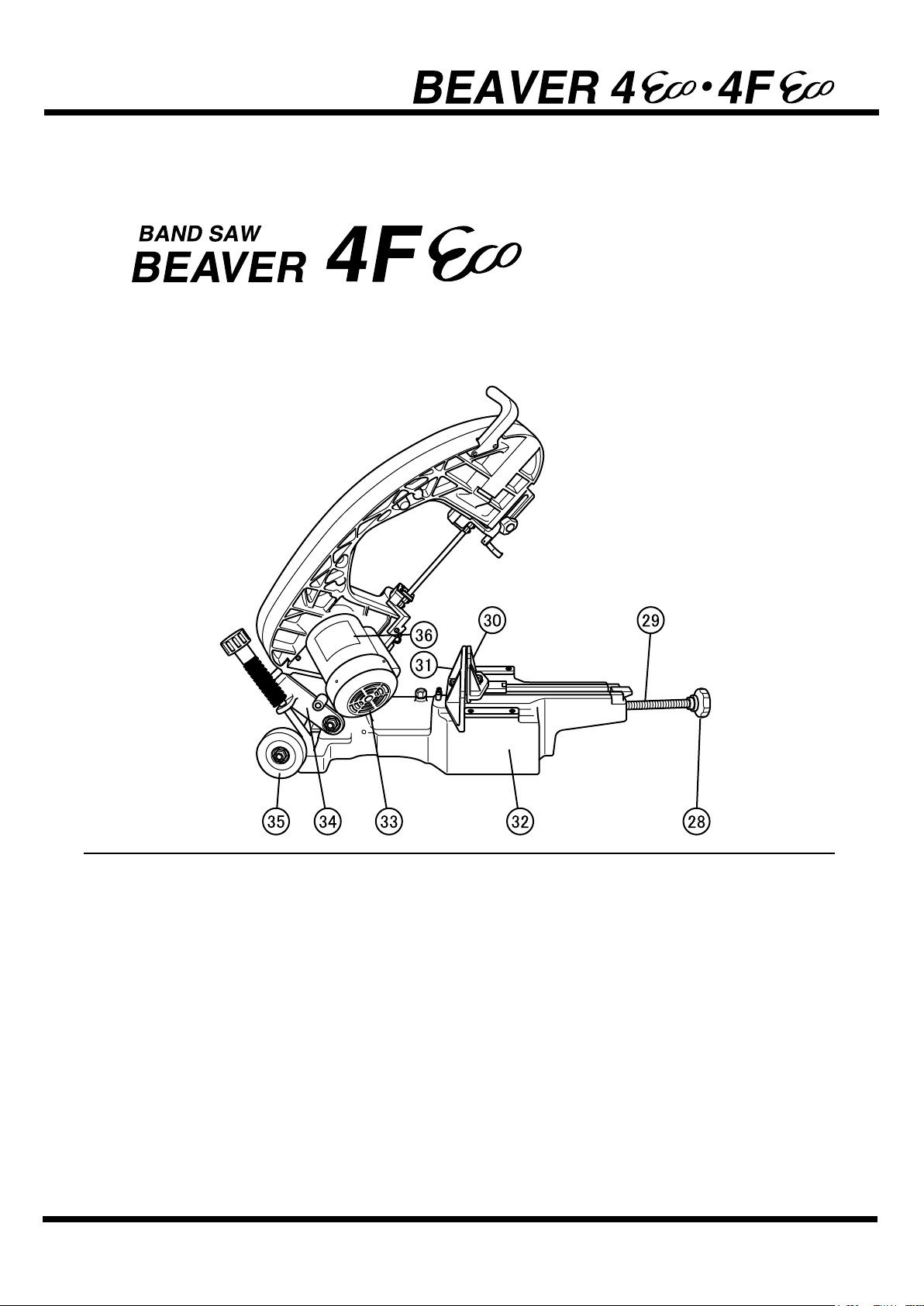

1.COMPONENTS OF THE MACHINE

1)Main Parts---------------------------------------------------------------------------------

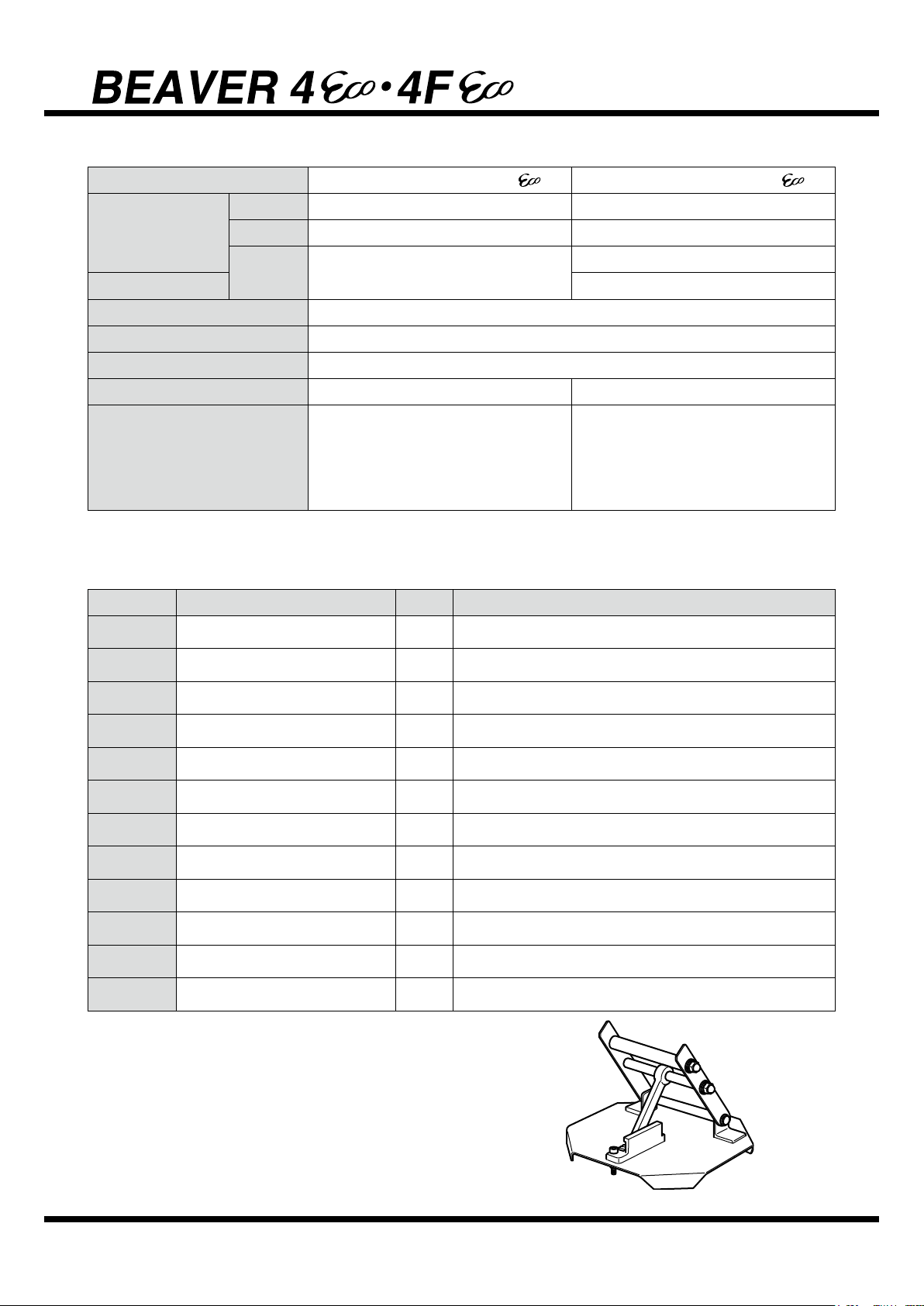

2)Specications-----------------------------------------------------------------------------

3)Optional Accessories--------------------------------------------------------------------

3-1)Work, Saw Blade and cutting load chart---------------------------------------

2.INSTALLATION

1)Carrying the Machine--------------------------------------------------------------------

2)Installation----------------------------------------------------------------------------------

3.OPERATION

1)Preparing for Operation-----------------------------------------------------------------

2)Setting the Workpiece(Chain Vise Type)-------------------------------------------

3)Cutting---------------------------------------------------------------------------------------

4)Removing the Workpiece---------------------------------------------------------------

2)Setting the Workpiece(Flat Vise Type)----------------------------------------------

3)Cutting---------------------------------------------------------------------------------------

4)Removing the Workpiece---------------------------------------------------------------

5)Cleaning after Use------------------------------------------------------------------------

6)Safekeeping--------------------------------------------------------------------------------

4.MAINTENACE & INSPECTION

1)Replacement of Parts

1-1)Replacement the Saw Blade------------------------------------------------------

1-2)Replacement the Pulley Rubber--------------------------------------------------

2)Correction Procedure for Oblique Cutting------------------------------------------

3)Daily Inspection and Maintenance---------------------------------------------------

5.BEFORE ASKING FOR REPAIRS-----------------------------------------------------

6.ELECTRICAL WIRING DIAGRAM-----------------------------------------------------

8

10

10

11

12

12

14

16

16

16

17

17

17

18

18

18

19

20

22

23

25