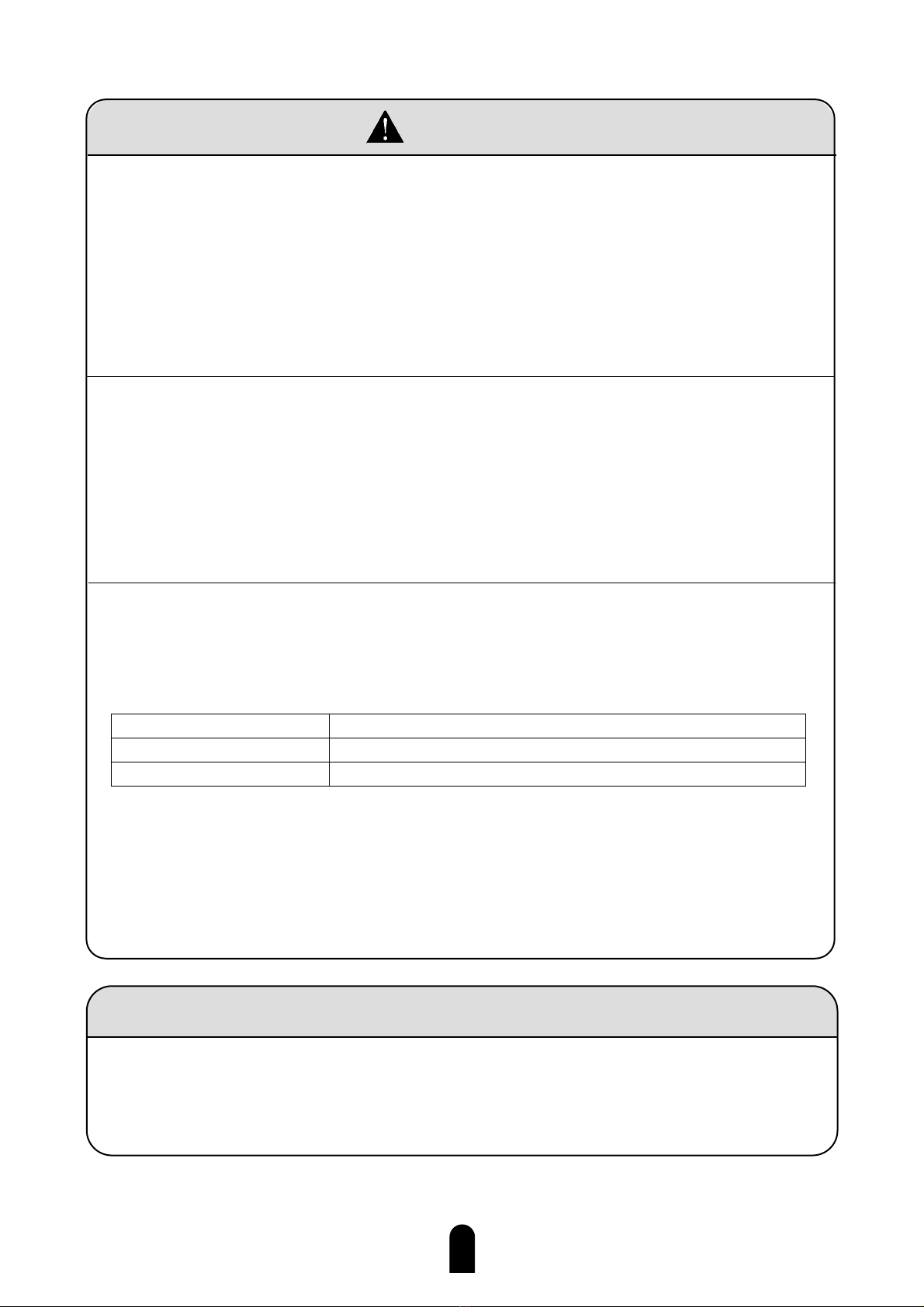

15

S

mptom Cause Remed

1. No fluid pressure ①Air regulator valve not opened. ①Fully open (turn clockwise).

②Defective pressure gauge ②Replace it with a new one.

③Poor cleaning: Pump valve stuck due

to hardened paint ③Flush thoroughly with thinner.

If hardened paint still remains after that,

disassemble pump and clean.

2. Pressure does

not rise to

working

pressure

①Air in fluid passage ①Pull spray gun trigger for air bubble purging

through fluid circulation.

②Insufficient fluid supply ②Replenish fluid.

③Worn V packings ③, ④Replace V packings following V

Packing Replacement Procedure.

④V packing installed in reversed

direction

⑤Clogged suction filter not sucking

enough ⑤Clean suction filter (8).

3. Pump runs, but

amortizing

poorly

①Insufficient compressed air supply

capacity ①Replace compressor with one with larger

capacity.

②Compressed air supply hose too small

in diameter ②Use larger hose in terms of diameter.

③Much compressed air consumed

elsewhere ③Provide a separate compressed air source

for exclusive use.

④Air regulator not operating properly or

setting pressure too low ④Readjust.

⑤Insufficient fluid ⑤Replenish fluid.

⑥Clogged material filter ⑥Clean filter.

⑦Worn air motor valve or pump packing ⑦Replace perishable parts with new ones

following Parts Replacement Procedure.

⑧Nozzle of filter clogged with foreign

materials ⑧Flush and clean.

⑨Worn nozzle ⑨Replace nozzle with a new one.

(If worn too fast, suspect nozzle

compatibility with fluid. Also, if pressure too

high, nozzle service life gets shorter.)

4. Fluttering spray

and tails ①(1) through (9) per 3 above, apply ①Check (1) through (9) per 3 above.

②Fluid viscosity too high ②Adjust viscosity to proper level.

5. Pump does not

stop when stop

spraying

①No fluid ①Replenish fluid.

②Leak from fluid passage ②Bring fluid pressure down to zero and

retighten.

③Worn V packings ③Replace V packings with new ones.

6. Pump fails to

operate if

compressed air

introduced

①Seizure of rod and oiles metal ①Disassemble and clean rod and metal.

Replace oil seal with new one.

If damage is found to rod or metal replace.

②Packing retainer, (2) on page 24, too

tight ②Loosen packing retainer.

The retighten it by hand until you can not

turn it any further.

Then turn it about another 15~30using

a spanner. That will be tight enough.

7. Air leak

(Sound is heard

when air leaks)

①Air valve is stuck in middle of stroke ①Remove cap and lift trip rod.

②Air valve is defective ②Replace

③Spring is defective ③Replace

8. Pump operates,

but output low ①Clogged suction filter ①Remove and clean.

If filter gets clogged all too soon, suspect

incompatibility. Contact us.

②Worn V packings affecting suction

performance ②Replace packings with new ones

③Foreign materials between valve seat

and ball ③Remove and clean

9. Fluid flow

suddenly stops

while spraying

Clogged nozzle Dip nozzle into thinner for a while to make

foreign materials softer. Then blow out with

compressed air from the opposite end.

Troubleshooting