Ascon Tecnologic - TRH22 - OPERATING INSTRUCTIONS - PAG. 2

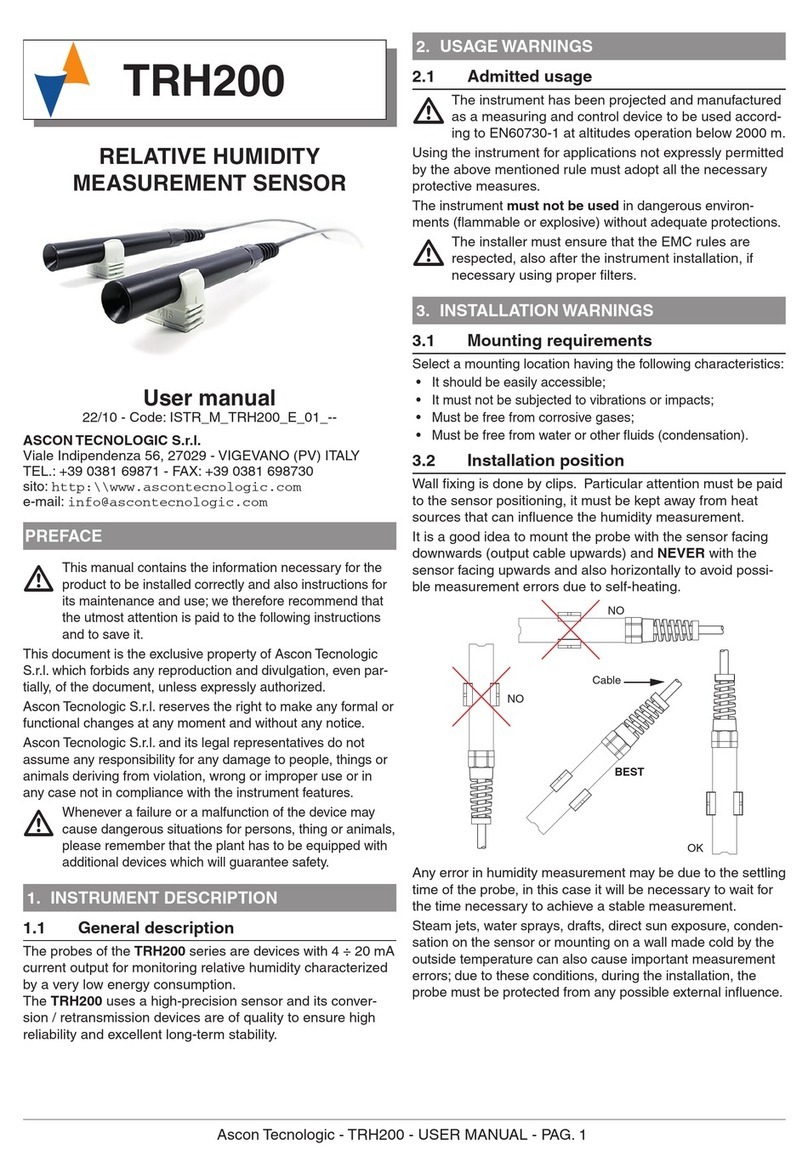

2.5.2 Wiring diagram with external supply

8 ÷ 24 VDC

Humidity probe

Temperature probe

INPUT +

4 ÷ 20 mA

INPUT -

4 ÷ 20 mA

+

-

GREEN

WHITE

TRH 22

YELLOW

BROWN

+

Supply HUMIDITY

+ 8 ÷ 24 VDC

OUT TEMPERATURE

4 ÷ 20 mA

OUT HUMIDITY

4 ÷ 20 mA

T

V+H

V+T

RH

Supply TEMPERATURE

+8 ÷ 24 VDC

INPUT +

4 ÷ 20 mA

INPUT -

4 ÷ 20 mA

3. OPERATING MODE

The instrument to which the probe is to be connected must

have a normalized current input of 4 ÷ 20 mA type.

To obtain the correct measure indication it is necessary to

set the lower and upper input limits.

These limits are the values that are to be displayed when 4

mA (lower limit or beginning of scale) and 20 mA (upper limit

or ending of scale) are present on the input circuit.

Consult the instrument’s instruction manual to correctly set

these limits.

The values that are to be set for the TRH 22 probes are:

Lower humidity measurement limit (4 mA): 0;

Upper humidity measurement limit (20 mA): 100;

Lower temp. measurement limit (4 mA): -30 (°C) or -22 (°F);

Upper temp. measurement limit (20 mA): 70 (°C) or 158 (°F).

4. PROBLEMS AND MAINTENANCE

4.1 Measurement errors

Reading errors can occur if settling time is too short or be

caused by steam, sprayed water, air drafts, direct exposure

to sunlight, or presence of condensation on the sensor.

To obtain accurate measurements the sensor should be left

to settle in the existing atmosphere for some time.

In order to avoid the condensation possibility on the humid-

ity sensor, make sure that the probe is placed in a ventilated

place and that it is not subject to sudden and high tempera-

ture variations (from cold to warm).

4.2 Cleaning

We recommend cleaning of the instrument only with a slightly

wet cloth using water and not abrasive cleaners or solvents.

Should be necessary to remove the protective cap, avoid touch-

ing the humidity sensor surface and mechanically stressing it.

4.3 Disposal

The appliance (or the product) must be

disposed of separately in compliance

with the local standards in force on

waste disposal.

5. WARRANTY AND REPAIRS

The instrument is under warranty against manufacturing flaws

or faulty material, that are found within 18 months from deliv-

ery date. The warranty is limited to repairs or to the replace-

ment of the instrument.

The eventual opening of the housing, the violation of the instru-

ment or the improper use and installation of the product will

bring about the immediate withdrawal of the warranty effects.

In the event of a faulty instrument, either within the period of

warranty, or further to its expiry, please contact our sales de-

partment to obtain authorisation for sending the instrument to

our company.

The faulty product must be shipped to Ascon

Tecnologic with a detailed description of the faults found,

without any fees or charge for Ascon Tecnologic, except in

the event of alternative agreements.

6. TECHNICAL DATA

6.1 Electrical characteristics

Power supply: 8 ÷ 24 VDC;

Power consumption: 20 mA + 20 mA max.;

Humidity sensor type: Capacitive-Digital;

Temperature sensor type: Thermistor-Digital;

Measurement circuit impedance:

[(V supply. -8 V)/0.02 A] ±50W;

Humidity output signal: 4 ÷ 20 mA (0 ÷ 100% RH);

Temperature output signal: 4 ÷ 20 mA (-30 ÷ 70°C/-22 ÷ 158°F);

Protection class against electric shock: Class III.

6.2 Mechanical data

Housing: Self-extinguishing plastic;

Dimensions: L 185 mm, Ø 20 mm;

Weight: 80 g approx.;

Mounting: Wall mounting ;

Connections: Non-detachable flexible PVC cable

4 x 0.25 mm2, L 1.5 m;

Box protection: IP 65;

Air filter: Wire mesh;

Operating temperature: -10 ÷ 70°C;

Operating humidity: 0 ÷ 100 RH%;

Storage temperature: -10 ÷ 70°C.

6.3 Functional features

Humidity measurement range: 5 ÷ 95% RH (4.8 ÷ 19.2 mA);

Temperature measurement range: -10 ÷ 70°C/14 ÷ 158°F

(7.2 ÷ 20 mA);

Overall humidity accuracy: ±3% (20 ÷ 80 %RH);

±5% (5 ÷ 20 and 80 ÷ 95% RH) with no pollutant presence, at

23°C and with an air speed of 3 m/s;

Overall temperature accuracy: ±1.5°C;

Response time: 30 s (at 23°C and with an air speed of 3 m/s);

Compliance: ECC directive EMC 2004/108/CE (EN 61326),

ECC directive LV 2006/95/CE (Instrument operating under

50 VAC and 75 VDC).