Ascon Tecnologic - TRH301 - USER MANUAL - PAG. 1

TRH301

RELATIVE HUMIDITY

AND TEMPERATURE

MEASUREMENT SENSOR

User manual

22/10 - Code: ISTR_M_TRH301_E_01_--

ASCON TECNOLOGIC S.r.l.

Viale Indipendenza 56, 27029 - VIGEVANO (PV) ITALY

TEL.: +39 0381 69871 - FAX: +39 0381 698730

sito: http:\\www.ascontecnologic.com

PREFACE

D This manual contains the information necessary for the

product to be installed correctly and also instructions for

its maintenance and use; we therefore recommend that

the utmost attention is paid to the following instructions

and to save it.

This document is the exclusive property of Ascon Tecnologic

S.r.l. which forbids any reproduction and divulgation, even par-

tially, of the document, unless expressly authorized.

Ascon Tecnologic S.r.l. reserves the right to make any formal or

functional changes at any moment and without any notice.

Ascon Tecnologic S.r.l. and its legal representatives do not

assume any responsibility for any damage to people, things or

animals deriving from violation, wrong or improper use or in

any case not in compliance with the instrument features.

D Whenever a failure or a malfunction of the device may

cause dangerous situations for persons, thing or animals,

please remember that the plant has to be equipped with

additional devices which will guarantee safety.

1. INSTRUMENT DESCRIPTION

1.1 General description

The probes of the TRH301 series are devices characterized

by a very low energy consumption and with an external dis-

sipative element in the case of the 2-wire versions.

These features allow an excellent measurement accuracy

even in conditions of poor ventilation; all devices are also

built to have an excellent protection degree.

2. USAGE WARNINGS

2.1 Admitted usage

D The instrument has been projected and manufactured

as a measuring and control device to be used accord-

ing to EN60730-1 at altitudes operation below 2000 m.

Using the instrument for applications not expressly permitted

by the above mentioned rule must adopt all the necessary

protective measures.

The instrument must not be used in dangerous environ-

ments (flammable or explosive) without adequate protections.

D The installer must ensure that the EMC rules are

respected, also after the instrument installation, if

necessary using proper filters.

3. INSTALLATION WARNINGS

3.1 Mounting requirements

Select a mounting location having the following characteristics:

• It should be easily accessible;

• It must not be subjected to vibrations or impacts;

• Must be free from corrosive gases;

• Must be free from water or other fluids (condensation).

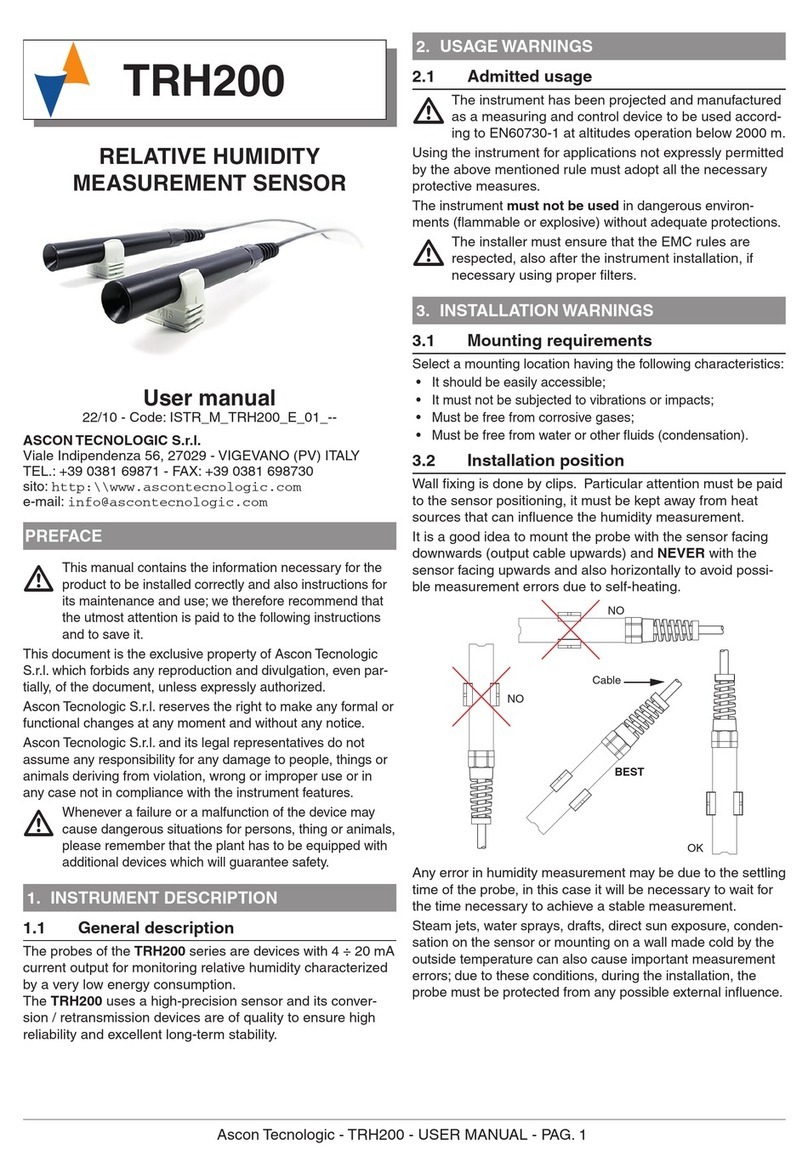

3.2 Installation position

Wall fixing is done by clips. Particular attention must be paid

to the sensor positioning, it must be kept away from heat

sources that can influence the humidity measurement.

In the design of the TRH301 probe, an attempt was made to

limit, as much as possible, the sensor self-heating possibility,

minimizing energy consumption and taking the dissipative

element necessary in the case of a 2-wire sensor away from

the sensor.

It is a good idea to mount the probe with the sensor facing

downwards (output cable upwards) and NEVER with the

sensor facing upwards and also horizontally to avoid possi-

ble measurement errors due to self-heating.

In the case the sensor filter should be cleaned, the pro-

be must be disassembled, then access the protective cap

(which can be replaced). Avoid touching the humidity sensor

and be careful not to lose the sealing o-rings.

NO

OK

NO

BEST

Cable