CSEBJ20T 3 1/26/2021

SETUP

Failure to follow these Setup Instructions may result in serious injury or death, and/or property damage.

1. Refer to the exploded view drawing on page 6 to identify jack components.

2. Assemble the pump handle sections together to make one complete handle. One end of the handle has a cut out that will fit over the

cross pin in the release valve in the base of the jack. This connection enables the user to turn the release valve in a clockwise direction

until tight in preparation for pumping the jack and raising the load. Slowly turning the release valve in a counterclockwise direction will

lower the load. It is not necessary to open the release valve more than two full rotations.

3. The opposite end of the pump handle must be inserted in the pump piston receiver linkage in preparation for pumping the jack. Install

an air quick disconnect fitting of your choice in the back of the air valve. The jack can be pumped up manually or by depressing the

air valve.

4. The ram is that portion of the jack which extends when the jack is pumped. There is a round saddle at the end of the ram which is the

part that makes contact with the load to be lifted. The saddle is actually part of a threaded extension screw that fits on the inside of the

ram. The saddle height can be extended by turning it in a counterclockwise direction. Extending the height of the saddle sometimes is

necessary when the full stroke of the ram is not adequate to lift a load to its desired work height.

5. Sometimes air gets trapped in the hydraulic system during shipment. An air bound hydraulic system feels spongy when pumped and may

not allow the jack to pump full incremental strokes.

PURGING AIR FROM THE HYDRAULIC SYSTEM:

a. Open the release valve by turning the handle in a counterclockwise direction two full turns from its closed position.

b. Pump the handle ten full strokes.

c. Close the release valve by turning the handle in a clockwise direction until tight.

d. Pump the jack until the ram is extended to maximum height.

e. Repeat steps "a" through "d" until air is purged from the system.

OPERATION

Failure to follow these Operating Instructions may result in serious injury or death, and/or property damage.

1. Do not lift more than one wheel of a vehicle at a time. Activate the hazard warning flasher, turn off ignition, move automatic selector to

park position or reverse gear if it is a manual transmission and set parking brake. The wheel diagonally opposite from the wheel being

lifted shall be chocked in both directions. Consult the vehicle manufacturer for the tire changing procedure and lift points.

2. Position the jack at the appropriate lift point. Estimate the required ram travel to raise the load to the desired height. If the desired height

exceeds the entire ram travel, unscrew the extension screw to make up the difference.

3. Pump the jack up until the saddle comes close to the lift point. Make sure the lift point is flat, parallel to the ground and free from grease,

any kind of lubricant, or debris. Continue pumping the jack to lift the load to the desired height. During lifting, inspect the position of the

jack in relation to the ground and the saddle in relation to the load to prevent any unstable conditions from developing. If conditions look

like they are becoming unstable, slowly lower the load and make appropriate setup corrections after the load is fully lowered.

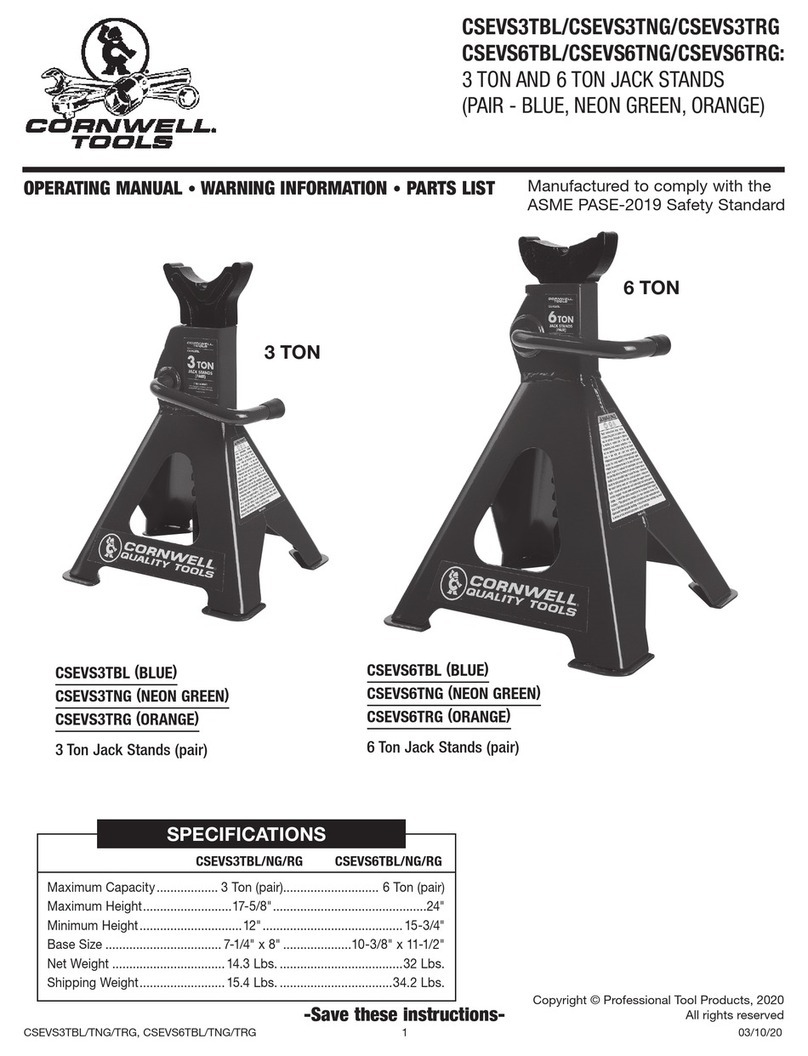

4. When the load is lifted to its desired height, immediately place jack stands in their designated locations and adjust the stands' support

columns up as close to the designated supports points as possible. Although jack stands are individually rated, they are to be used in a

matched pair to support the load. Slowly and carefully open the release valve of the jack in order to gently lower the load onto the jack

stands. Make sure the load is safely supported by the jack stands' saddles and not the locating lugs of the saddles. Inspect the

relationship of the jack stands with the ground and the jack stand columns and saddles with the load to prevent any unstable conditions.

If conditions look unstable, close the jack's release valve and pump the jack to raise the load off the jack stands. Make the

appropriate setup changes and slowly and carefully lower the load onto the jack stand saddles. DO NOT CRAWL UNDER VEHICLE

WHEN PLACING/REMOVING STANDS.

5. After the work is done, close the release valve and pump the jack high enough to remove the load from the jack stand saddles.

Be sure the load is stable. If it is not, lower the load back onto the jack stands. Make appropriate setup corrections and repeat the

step again. Remove the jack stands from under the load, being very careful not to move the load. DO NOT CRAWL UNDER VEHICLE

WHEN PLACING/REMOVING STANDS.

6. Open the jack's release valve very slowly and carefully to lower the load to the ground.

CSEBJ20T

20 Ton Air/Hydraulic

Bottle Jack

WARNING

WARNING