AC25/30Q-1 and -3 Operations Manual....5

7 SOFTWARE FEATURES.....................................................................................39

7.1 GENERAL.............................................................................................................39

7.2 LOAD MANAGEMENT.......................................................................................39

7.3 LOAD MANAGEMENT OPERATION...............................................................41

7.3.1 Shore Cord Alarm, Single, Master, and Slave Converters ........................41

7.3.2 Shore Cord Setup, Single, Master, and Slave Converters..........................42

7.3.3 Voltage Droop, Single or Master Converters ............................................43

7.3.4 Automatic Transfer to Generator, Single or Master Converters................44

7.3.5 Quick Setup of Shore Cord Alarm, Single, Master, and Slave Converters45

7.4 GENERATOR FREQUENCY ANALYSIS..........................................................46

7.5 CONVERTER OUTPUT IMPEDANCE CONTROL...........................................46

7.6 AGC CONTROL...................................................................................................47

7.7 kW-HOUR METER AND MAX POWER LEVEL DISPLAY............................48

7.8 CONVERTER OUTPUT VOLTAGE CONTROL...............................................49

7.9 EVENT LOG.........................................................................................................50

8 TROUBLE-SHOOTING AND DIAGNOSTICS..............................................................52

8.1 COMMON PROBLEMS.......................................................................................52

8.2 FAILURE AND WARNING MESSAGES...........................................................53

8.3 INFO DISPLAY ....................................................................................................53

8.4 STATUS WORDS.................................................................................................54

8.5 GATHERING DATA............................................................................................54

8.6 SOFTWARE TOOLS............................................................................................54

9 CALIBRATION ................................................................................................................56

10 MAINTENANCE..............................................................................................................58

11 INTERNATIONAL POWER FORM REFERENCE........................................................59

12 INDEX...............................................................................................................................66

FIGURES

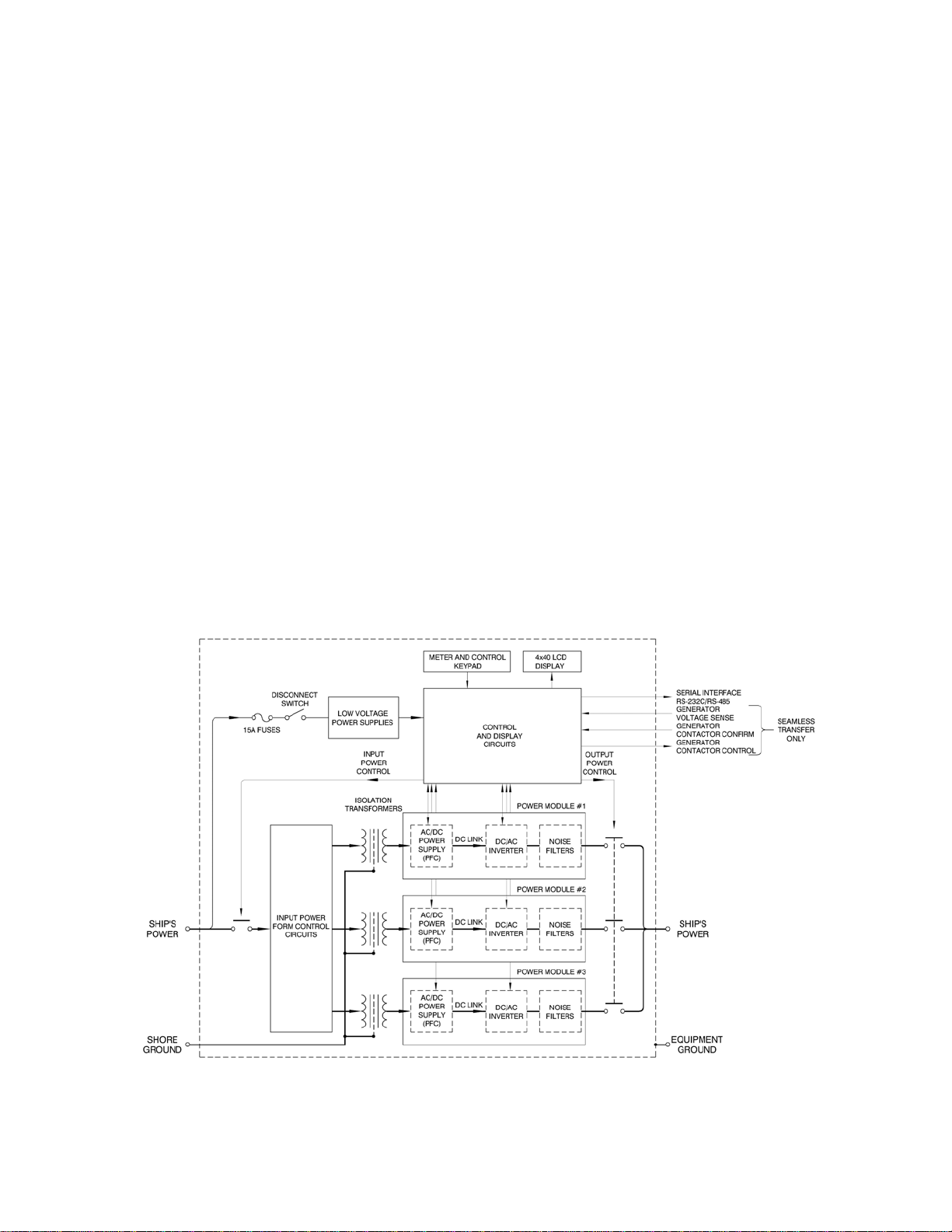

1 SYSTEM BLOCK DIAGRAM...............................................................................8

2 MECHANICAL OUTLINE...................................................................................16

3 CONTROLS ..........................................................................................................17

4 INPUT AND OUTPUT CONNECTIONS............................................................21

5 CONTROL MODULE CIRCUIT BOARDS ........................................................23

6 FRONT PANEL CONTROLS ..............................................................................26

7 RS-232C PINOUT.................................................................................................37

8 RS-485 CONNECTIONS......................................................................................38

9 STATUS WORD BIT DEFINITIONS..................................................................55