AC50Q-3 / AC63Q-3 / AC75Q-3 Operations Manual....5

7 SOFTWARE FEATURES.................................................................................................39

7.1 GENERAL.............................................................................................................39

7.2 LOAD MANAGEMENT.......................................................................................39

7.3 LOAD MANAGEMENT OPERATION...............................................................41

7.3.1 Shore Cord Alarm, Single, Master, and Slave converters .........................41

7.3.2 Shore Cord Setup, Single, Master, or Slave Converters............................42

7.3.3 Voltage Droop, Single or Master Converters.............................................43

7.3.4 Automatic Transfer to Generator, Single or Master Converters (Seamless

Transfer installed)......................................................................................44

7.3.5 Quick Setup of Shore Cord Alarm, Single, Master, or Slave Converters..45

7.4 GENERATOR FREQUENCY ANALYSIS..........................................................46

7.5 CONVERTER OUTPUT IMPEDANCE CONTROL...........................................46

7.6 AGC CONTROL...................................................................................................47

7.7 kW-HOUR METER AND MAXIMUM POWER LEVEL DISPLAY.................48

7.8 CONVERTER OUTPUT VOLTAGE CONTROL...............................................49

7.9 EVENT LOG .........................................................................................................50

8 TROUBLE-SHOOTING AND DIAGNOSTICS ..............................................................52

8.1 COMMON PROBLEMS.......................................................................................52

8.2 FAILURE AND WARNING MESSAGES...........................................................53

8.3 INFO DISPLAY.....................................................................................................53

8.4 STATUS WORDS.................................................................................................54

8.5 GATHERING DATA............................................................................................54

8.6 SOFTWARE TOOLS............................................................................................54

8.7 POWER MODULE SWITCH...............................................................................56

8.8 POWER MODULE FUSES ..................................................................................56

9 CALIBRATION.................................................................................................................57

10 MAINTENANCE ..............................................................................................................59

11 INTERNATIONAL POWER FORM REFERENCE........................................................60

12 INDEX...............................................................................................................................67

FIGURES

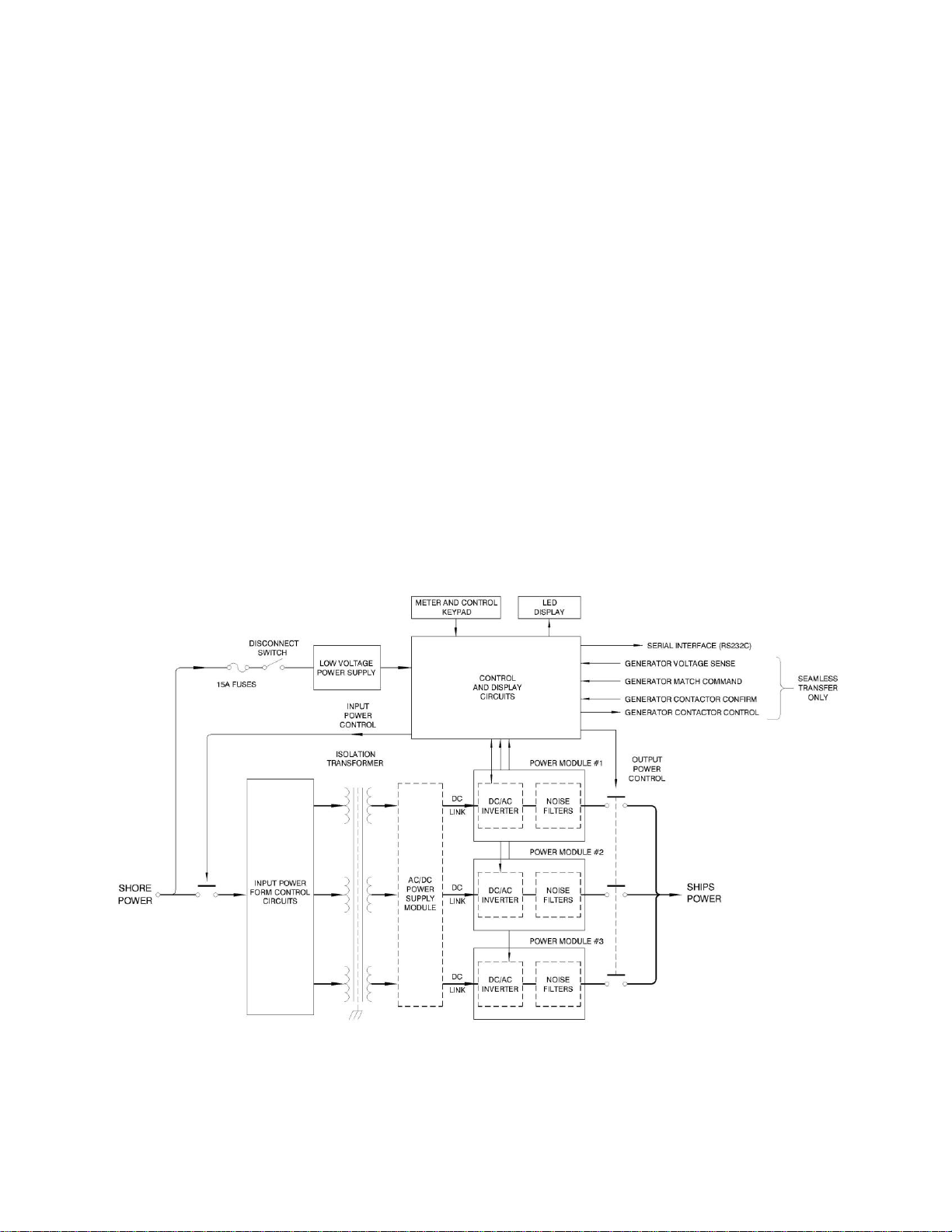

1 SYSTEM BLOCK DIAGRAM ...........................................................................................8

2 MECHANICAL OUTLINE...............................................................................................15

3 MECHANICAL OUTLINE...............................................................................................16

4 INPUT AND OUTPUT CONNECTIONS ........................................................................19

5 FRONT PANEL CONTROLS...........................................................................................24

6 RS-232C PINOUT.............................................................................................................35

7 RS-485 CONNECTIONS..................................................................................................36

8 STATUS WORD BIT DEFINITIONS ..............................................................................55

9 POWER MODULE SWITCH AND LED.........................................................................56

10 POWER MODULE FUSES ..............................................................................................56