AC25/30QTP-1 and -3 Operations Manual.... 4

TABLE OF CONTENTS

CERTIFICATION........................................................................................................................ 2

WARRANTY................................................................................................................................. 2

1USING THIS MANUAL ...................................................................................... 3

2SAFETY NOTICES.............................................................................................. 7

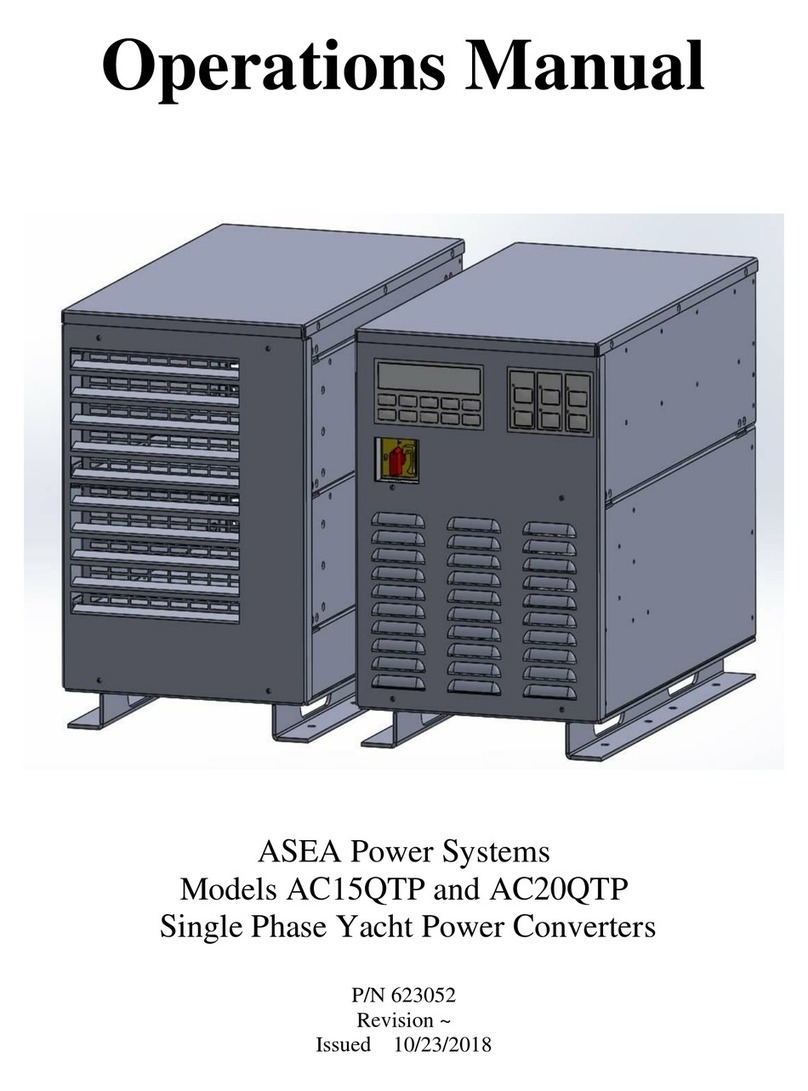

3INTRODUCTION TO THE AC25QTP AND AC30QTP............................... 10

3INTRODUCTION TO THE AC25QTP AND AC30QTP, cont. .................... 11

4SPECIFICATIONS............................................................................................. 12

4.1ELECTRICAL SPECIFICATIONS ..................................................................... 12

4.1.1Input Service............................................................................................. 12

4.1.2Output Service .......................................................................................... 12

4.1.3Control, Metering, and Status................................................................... 14

4.2PHYSICAL SPECIFICATIONS.......................................................................... 14

4.2.1Mechanical................................................................................................ 14

4.2.2Environmental........................................................................................... 14

5INSTALLATION................................................................................................ 15

5.1MECHANICAL INSTALLATION...................................................................... 16

5.2ELECTRICAL INSTALLATION........................................................................ 20

5.2.1Input Power Connections.......................................................................... 22

5.2.2Output Power Connections....................................................................... 22

5.2.3Grounding................................................................................................. 25

5.2.4Multi-Cabinet Connections....................................................................... 26

5.2.5Seamless Transfer Connections................................................................ 27

5.2.6Other Optional Connections ..................................................................... 28

6OPERATION ...................................................................................................... 29

6.1POWER TURN-ON PROCEDURE..................................................................... 29

6.1.1Systems Not Equipped With The Seamless Transfer Option................... 31

6.1.2Systems Equipped With The Seamless Transfer Option.......................... 32

6.2MULTI-CABINET OPERATION........................................................................ 34

6.3AUTO-RESTART FEATURE ............................................................................. 35

6.3.1Operation................................................................................................... 36

6.4TURN-OFF PROCEDURE.................................................................................. 37

6.4.1Systems Not Equipped With The Seamless Transfer Option................... 37

6.4.2Systems Equipped With The Seamless Transfer Option.......................... 38

6.5REMOTE COMMUNICATIONS........................................................................ 39

6.5.1RS-232C/SCPI.......................................................................................... 40

6.5.2RS-485/Modbus........................................................................................ 41

7SOFTWARE FEATURES ................................................................................. 42

7.1GENERAL............................................................................................................ 42