ASG, Division of Jergens, Inc.

15700 S. Waterloo Road | Cleveland, OH 44110-3898 | Phone: (888) 486-6163 | Fax: (216) 481-4519 | Email: asginfo@asg-jergens.com | Web: www.asg-jergens.com | Revision: 11/14/2019 | Page 1 of 10

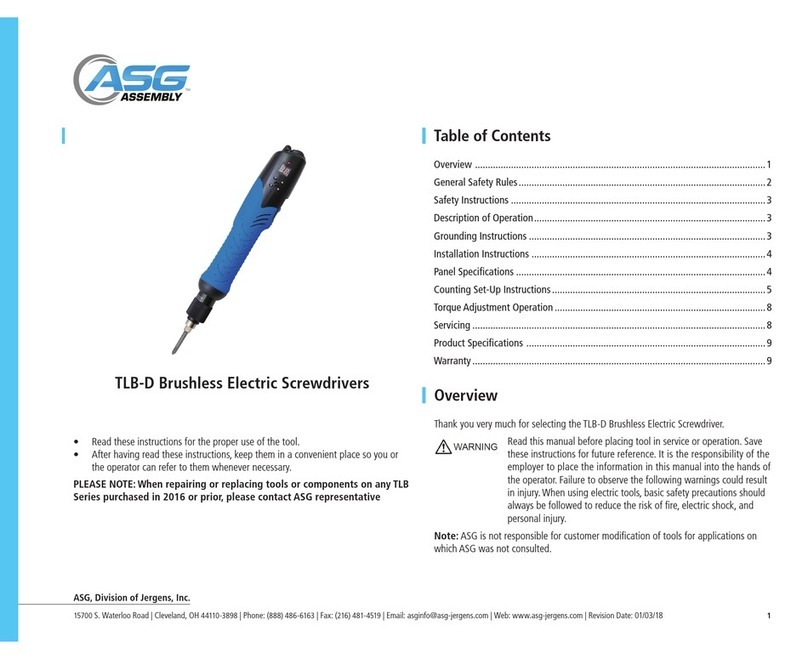

ASG Mini Digital Torque Wrenches and Screwdrivers

Operation Manual

Overview

Thank you for choosing an ASG product. We know you had a choice of electric screwdrivers

and we are pleased you chose ASG. Please read these instructions and make sure your

operators understand how to operate this product properly. Should your tool need to be

or 888-486-6163.

Standard Equipment

The mini digital torque wrenches and screwdrivers are supplied with:

• 1, AAA battery

• Part #728085, Blow molded plastic case,

• Part #728086, USB Communication cable*

• Part #728088, 1/4” hex 5mm insert bit (screwdrivers only)

• Part #728087, 1/4” hex #0 x 65 mm Phillips bit (screwdrivers only)

• Software can be downloaded on the product page at www.asg-jergens.com or

www.asg-express.com

• NOTE: Uploader software not compatible with and USB cable not included with

earlier #65110 and #65111 SP series and #65112 and #65113 DP2 series tools.

Table of Contents

Tool Features Overview ..............................................................................................1

Identication of Parts .................................................................................................2

Specications.............................................................................................................2

Installing the Battery ..................................................................................................3

Display and Button Features .......................................................................................3

Setting the Target Torque............................................................................................4

Setting the Torque Units .............................................................................................5

Setting Peak/Track Mode ...........................................................................................5

Setting Memory Presets..............................................................................................6

Operating In Peak Mode.............................................................................................6

Store Readings in Memory..........................................................................................6

Operating in Track Mode.............................................................................................7

Manage Stored Data in the Wrench ............................................................................7

View Stored Readings in the Wrench...........................................................................7

Clear the Memory in the Wrench ................................................................................7

Manage Stored Data in the Screwdriver ......................................................................8

View Stored Readings in the Screwdriver ....................................................................8

Clear the Memory in the Screwdriver ..........................................................................8

Download Data to PC.................................................................................................8

Tool Features Overview

The ASG Mini Digital torque tools are compact light weight electronic torque tools

with many standard features. The tools feature an audible alarm to alert the operator

when they are close to the desired torque and when the desired torque is reached or

exceeded. The tools can be operated in either peak or track mode. The tools can be

set up to 9 preset torques allowing the tools to be easily switched from one assembly

to another without complicated programming. The tools can store up to 250 torque

readings in their memory. These readings can be downloaded to a PC using the

included software and USB cable supplied with each tool*. The tools will power off

after being idle for about 5 minutes to save battery power (except when the tool is in

communication mode).