6. Adjust until the desired torque setting

is reached. Turn the screwdriver several

more times on the tester and ne tune

the setting to as repeatable a number

as possible. Replace end cap.

7. Install the proper bit into the hex

receiver and the screwdriver is ready

to use.

8. To torque fastener, keep hand

centered on the handle. Turn handle

until a click/impulse is heard or

felt. Stop turning, the screwdriver

will automatically reset for the next

operation.

Use perpendicular in line with

fastener

SIDE LOADING NOTE: When applying

torque the screwdriver must be

kept perpendicular to the plane of

use (either horizontal or vertical).

Inaccuracies in torque readings may

occur from applying a “side load.”

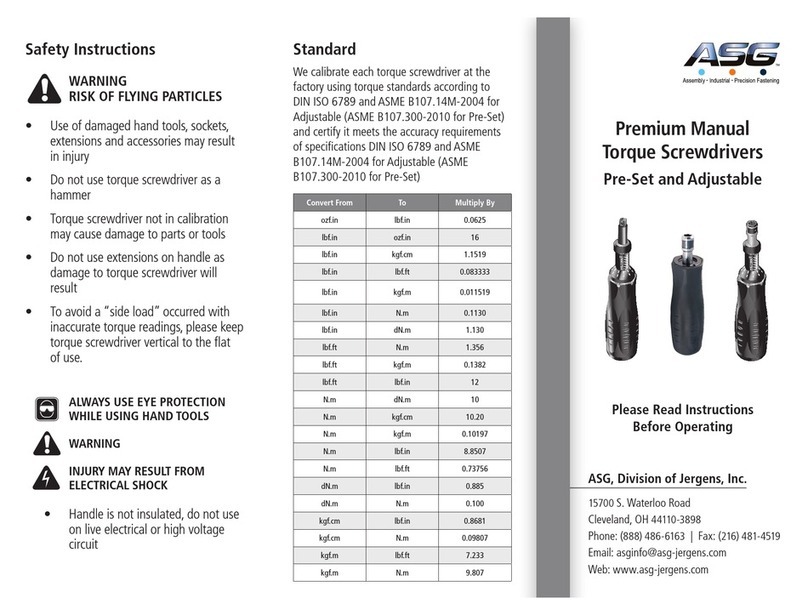

Safety Messages

WARNING

Read operation manual completely before

using torque instrument and store for future

reference.

Wear safety goggles - both user and

bystanders

• An out of calibration torque wrench

can cause part or tool breakage

• Periodic re-calibration is necessary to

maintain accuracy

• Do not exceed rated torque as

overtorquing can cause wrench or

part failure

• Broken or slipping tools can cause

injury

Maintenance/Service

1. The torque screwdrivers internal

mechanism is permanently lubricated

during assembly. Do not attempt to

lubricate the internal mechanism.

2. Clean torque screwdriver by wiping.

Do not immerse.

Adjustments of Torque Settings

To set screwdriver to desired torque:

1. Determine proper torque to be applied

to the fastener.

2. Use a certied torque tester that is

accurate within a range suited to

screwdriver torque range

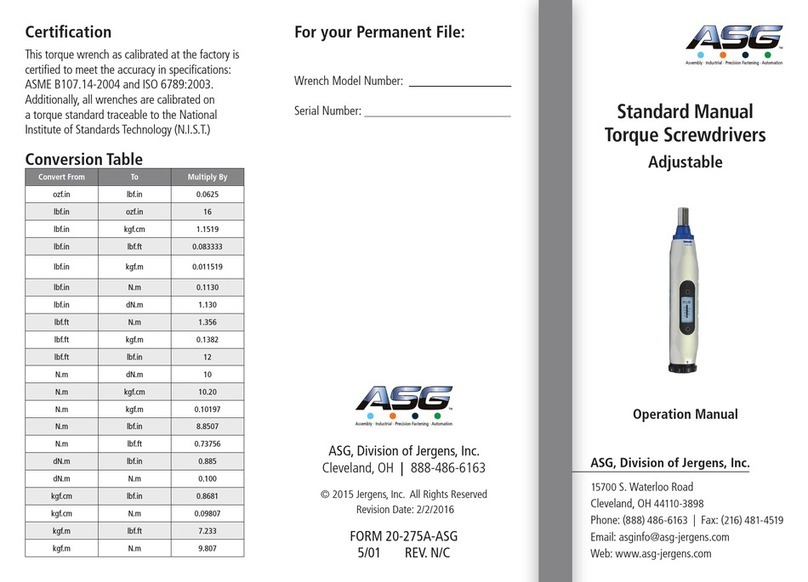

3. Remove end cap at the base of

screwdriver. (See Figure I)

4. Place screwdriver on tester and cycle

several times observing the torque

setting displayed on the tester.

5. With a 1/8” hex key adjust the set

screw at the base of the preset torque

screwdriver. Turn clockwise (CW) to

increase the amount of torque and

counter-clockwise (CCW) to decrease

the amount of torque.

Figure I

Removable

End Cap

Tri-Lobed

Body

1/4”

Female

Hex

Driver performs at +/- 6% of full scale