Installation and Maintenance Instructions for

28HPX High Purity Gauge

© Ashcroft Inc. 2020, 250 East Main Street, Stratford, CT 06614-5145, USA, Tel: 203-378-8281, Fax: 203-385-0357, www.ashcroft.com

All sales subject to standard terms and conditions of sale. 28_HPX_Gauge_im_RevA_(I&M011-10276)_04-03-20 1

Table of contents:

1. INTRODUCTION ................................................................. 1

2. APPLICATION ..................................................................... 1

3. TRANSPORTATION, STORAGE, UNPACKING

PRECAUTION...................................................................1-2

4. DRAWING............................................................................ 2

5. INSTALLATION.................................................................... 2

6. OPERATION ........................................................................ 2

7. MAINTENANCE................................................................... 2

8. TROUBLESHOOTING......................................................2-3

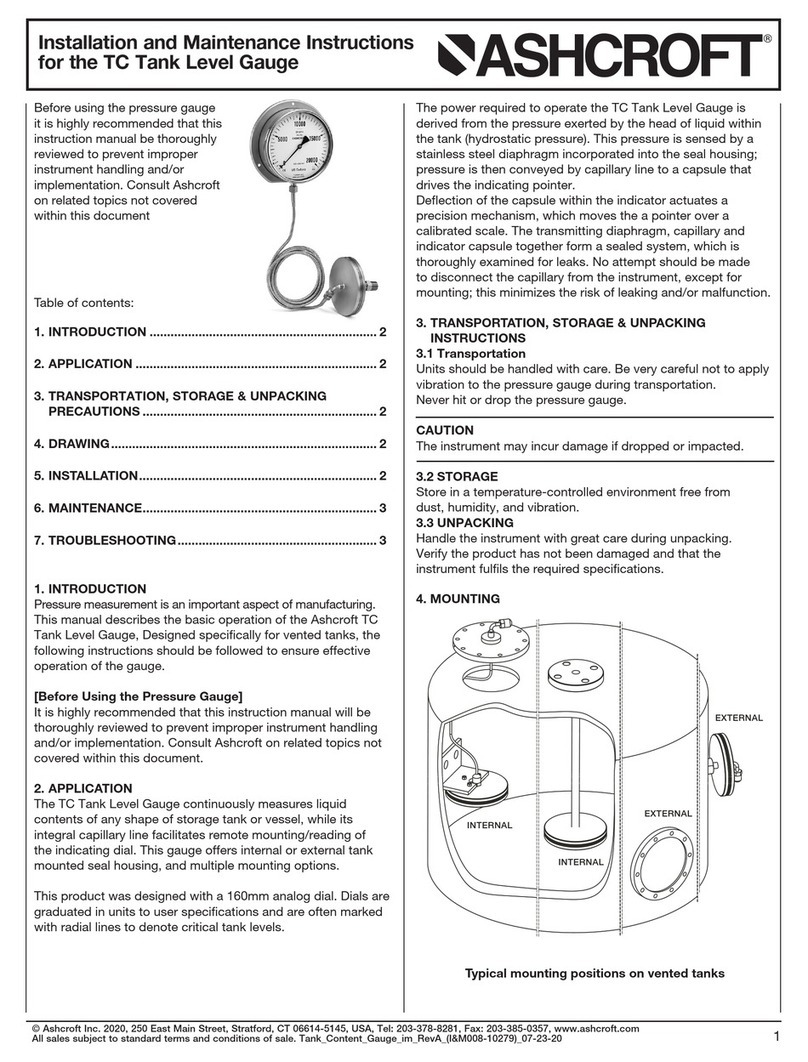

1. INTRODUCTION

Pressure measurement is an important aspect of manufac-

turing. Advancement of equipment and plant engineering

technology requires higher performance and more versatile

instrument functions.

The Ashcroft model 28HPX High-Purity pressure gauge is

similar to an ordinary instrument, yet has been assembled

under a significantly different process where treatment,

control, and inspection are rigidly maintained. This manual

describes the basic operation of this product for the semi-

conductor industry while adhering to the following instruc-

tions will ensure its proper and effective application.

[Before Using Pressure Gauge]

It is highly recommended that this instruction manual be

thoroughly reviewed to prevent improper instrument handling

and/or implementation. Consult Ashcroft on related topics

not covered within this document.

[Warranty]

Instruments are repaired or replaced, at no cost, if deter-

mined to be within the 1-year warranty period and non-con-

forming in accordance with defects due to design or manu-

facture by Ashcroft. Please note that the following instances

are excluded.

1. Delivered products are disassembled, altered, parts

replaced, or where any new function is added by the user

or any third party.

2. Directions described within the instruction manual or cata-

log have not been observed.

3. Non-conformance is caused by deterioration due to use,

natural disaster, fire or other force majeure events.

4. Secondary damage caused by the non-conformance of

the products including the above.

Regardless of recognized mishandling, any apparent evi-

dence of deformation, abrasion, burnout, or other identified

issue shall be excluded from the warranty scope with the

cost being incurred by the customer.

[Definition of Safety Terms]

Safety precautions within this manual have been classified

as follows:

DANGER - Ignoring this warning may result in serious

injury or death.

WARNING - Ignoring this warning may result in serious

injury or death.

CAUTION - Ignoring this warning may result in the material

damage and render instrument performance defective.

2. APPLICATION

This pressure gauge has an electropolished wetted sur-

face for measuring materially-compatible gas pressure (EP

grade). The pressure gauge is fabricated in accordance with

high cleanliness and tightly sealed standards. Consequently,

the model 28HPX High-Purity pressure gauge is ideally

suited for pressure measurement within the semiconductor

production process, etc.

The product footprint design is ultra-compact and incor-

porates a 1.125˝ surface mount. The pressure element is a

diaphragm which facilitates easy maintenance for cleaning

and gas flushing.

The instrument’s pressure element is a thin wall diaphragm.

Do not use the pressure gauge with the wetted material

exposed to any corrosive gas or atmosphere. Additionally,

it is industry practice for the gas detector’s to be installed

within the same environment; this will provide an alert to

escaping gas that may adversely affect people and/or

equipment

3. TRANSPORTATION, STORAGE, UNPACKING PRECAUTION

3.1 Transportation

Units should be handled the same as electronic or test mea-

surement instruments. Be very careful not to apply vibration

to the pressure gauge during transportation.

Never hit or drop the pressure gauge.

CAUTION

The instrument may incur damage if dropped/impacted.

3.2 Storage

Store in a temperature-controlled environment free from

dust, humidity, and vibration. Prevent temperature variances

as this may result in condensation developing in the product.

28HPX High Purity Gauges