© 2021 Ashcroft Inc., 250 E. Main St., Stratford, CT 06614-5145, Tel: 203-378-8281, Fax: 203-385-0408, www.ashcroft.com

All sales subject to standard terms and conditions of sale. I&M011-10296_RevA_08-12-21

ZL91 FLUOROPOLYMER PRESSURE

TRANSDUCER INSTALLATION AND

MAINTENANCE SHEET

WARNING! READ

BEFORE INSTALLATION

1. GENERAL:

A failure resulting in injury or dam-

age may be caused by excessive

overpressure, excessive vibration

or pressure pulsation, excessive

instrument temperature, corrosion

of the pressure containing parts, or

other misuse. Consult Ashcroft Inc.,

Stratford, Connecticut, USA before

installing if there are any questions

or concerns.

2. OVERPRESSURE:

Pressure spikes in excess of the rated

overpressure capability of the trans-

ducer may cause irreversible elec-

trical and/or mechanical damage to

the pressure measuring and contain-

ing elements.

Fluid hammer and surges can de-

stroy any pressure transducer and

must always be avoided. A pressure

snubber should be installed to elimi-

nate the damaging hammer effects.

Fluid hammer occurs when a liquid

flow is suddenly stopped, as with quick

closing solenoid valves. Surges occur

when flow suddenly begins, as when

a pump is turned on at full power or a

valve is quickly opened.

Liquid surges are particularly damag-

ing to pressure transducers if the pipe

is originally empty. To avoid damaging

surges, fluid lines should remain full (if

possible), pumps should be brought

up to power slowly, and valves

opened slowly. To avoid damage from

both fluid hammer and surges, a surge

chamber should be installed.

Symptoms of fluid hammer and surge's

damaging effects:

• Pressure transducer exhibits an out-

put at zero pressure (large zero offset).

• Pressure transducer output remains

constant regardless of pressure

• In severe cases, there will be no output.

mm

FREEZING:

Prohibit freezing of media in pressure

port. Unit should be drained (mount

in vertical position with electrical ter-

mination upward) to prevent possible

overpressure damage from frozen media.

3. STATIC ELECTRICAL CHARGES:

Any electrical device may be sus-

ceptible to damage when exposed

to static electrical charges. To avoid

damage to the transducer observe the

following:

• Ground the body of the transducer

BEFORE making any electrical

connections.

• When disconnecting, remove the

ground LAST!

Note: The shield and drain wire in the

cable (if supplied) is not connected to

the transducer body, and is not a suit-

able ground.

Introduction

The ZL91 is a fluoropolymer pressure

transducer designed for ultrapure and

de-ionized water applications. It is con-

structed with PFA/PTFE wetted parts

that prevent metal ion elution and main-

tain the purity of your process fluid.

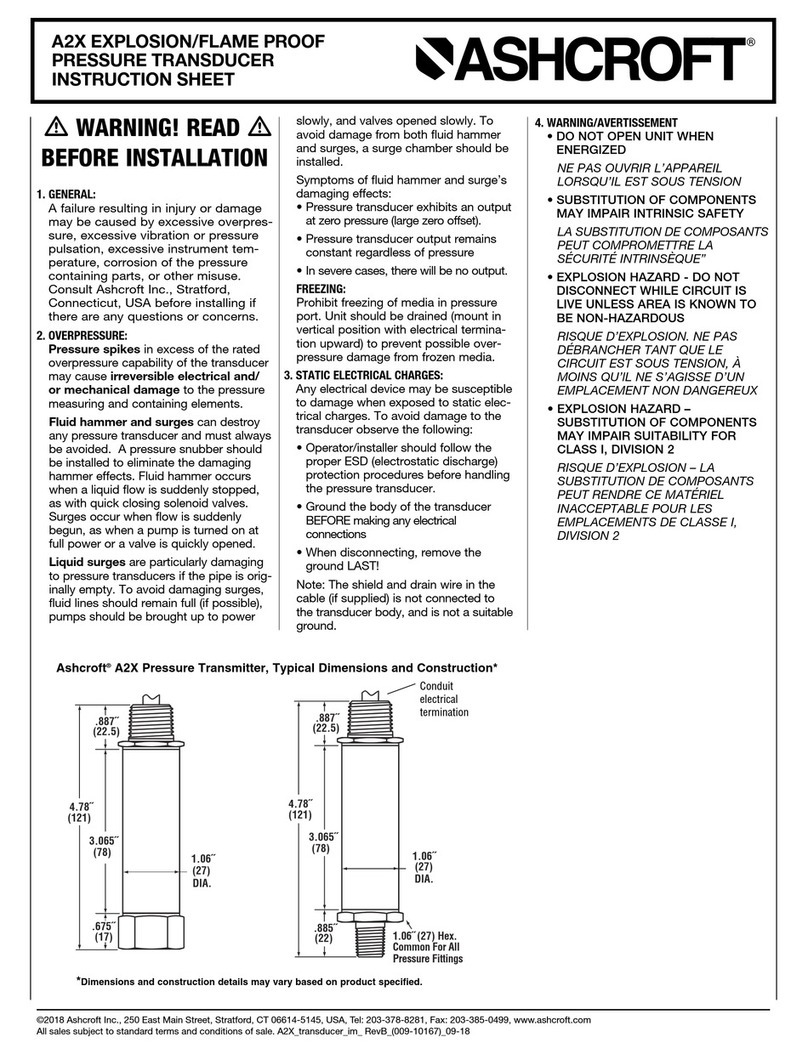

Mounting

When installing the ZL91, follow the

manufacturers recommended installa-

tion instruction for the specific compres-

sion fitting ordered.

When using the ZL91 with viscous

fluids, Ashcroft recommends that flow

through style transducers should be

mounted in the horizontal position to

reduce output errors.

Although the unit can withstand normal

vibration without damage or significant

output effects, it is always good practice

to mount the transducer where there is

minimum vibration.

Noise

For minimum noise susceptibility, avoid

running the transducer’s cable in a con-

duit that contains high current AC power

cables. Where possible avoid running

the cable near inductive equipment.

Shield Wiring - (Cable Termination Only)

Connect the braided shield to the guard

terminal on the reading instrument

(meter, etc.) if available or to ground or

to the power supply negative terminal.

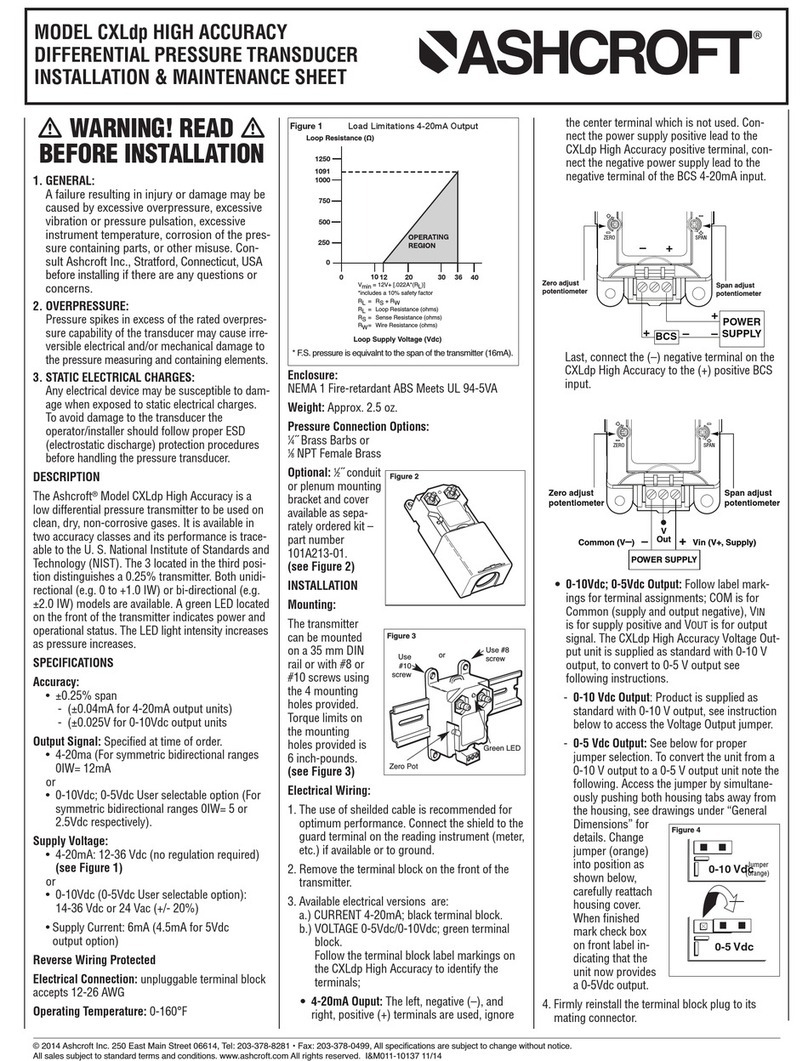

Calibration - Zero Output Adjustment

ZL91 offers a zero point adjustment

potentiometer. To access the zero poten-

tiometer remove the black cap from the

top of the ZL91. Turn the potentiometer

using a standard screwdriver.

Instructions for calibration:

1. Power Unit

2. With no pressure applied to the sen-

sor, verify output.

3. If output has shifted from its ideal

value, (4mA for current output and

1.0 V for voltage output) turn poten-

tiometer until the output has reached

its ideal value.

Storage

The ZL91 should be stored in a dry,

cool and dust free environment.

Maintenance

In general, a periodic inspection of the

ZL91 should be performed at least twice

a year or as needed. This inspection

should include

A. Visual inspection

B. Check of the pressure inlets for cor-

rosion, clogging or leaking

C. Verify the output using calibrated

gauges

The ZL91 is not field repairable and should

be returned to Ashcroft for evaluation.

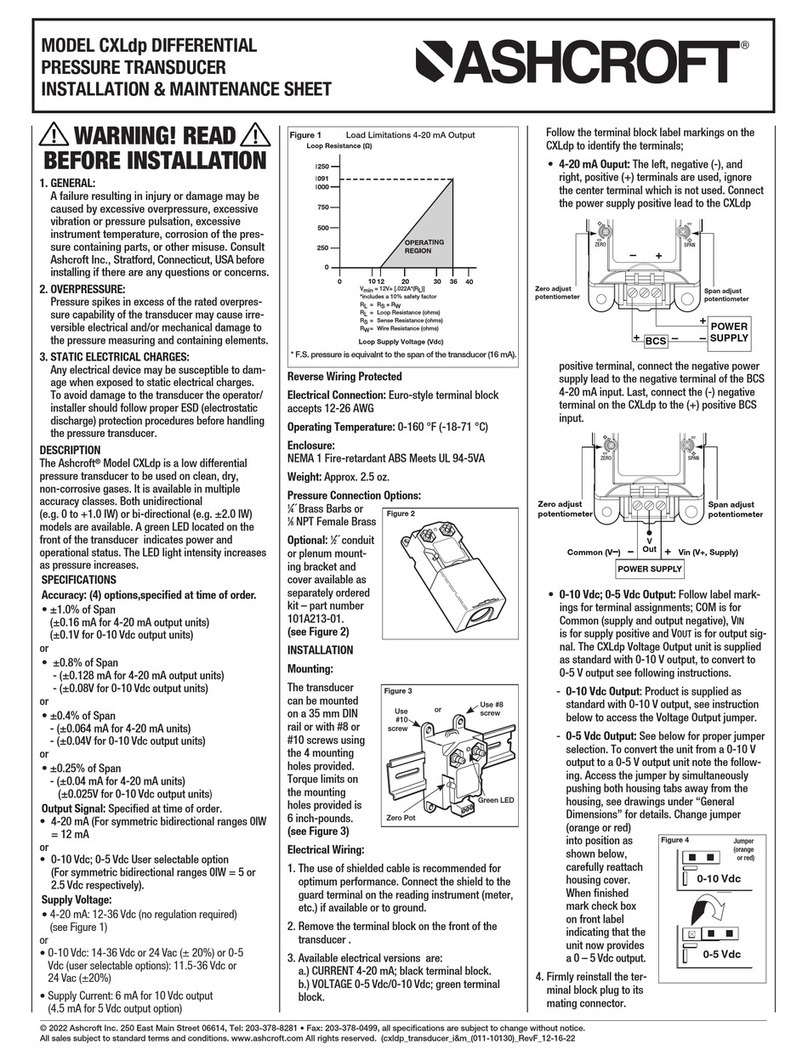

Wiring Diagrams

H

✔

HORIZONTAL VERTICAL

point adjustment

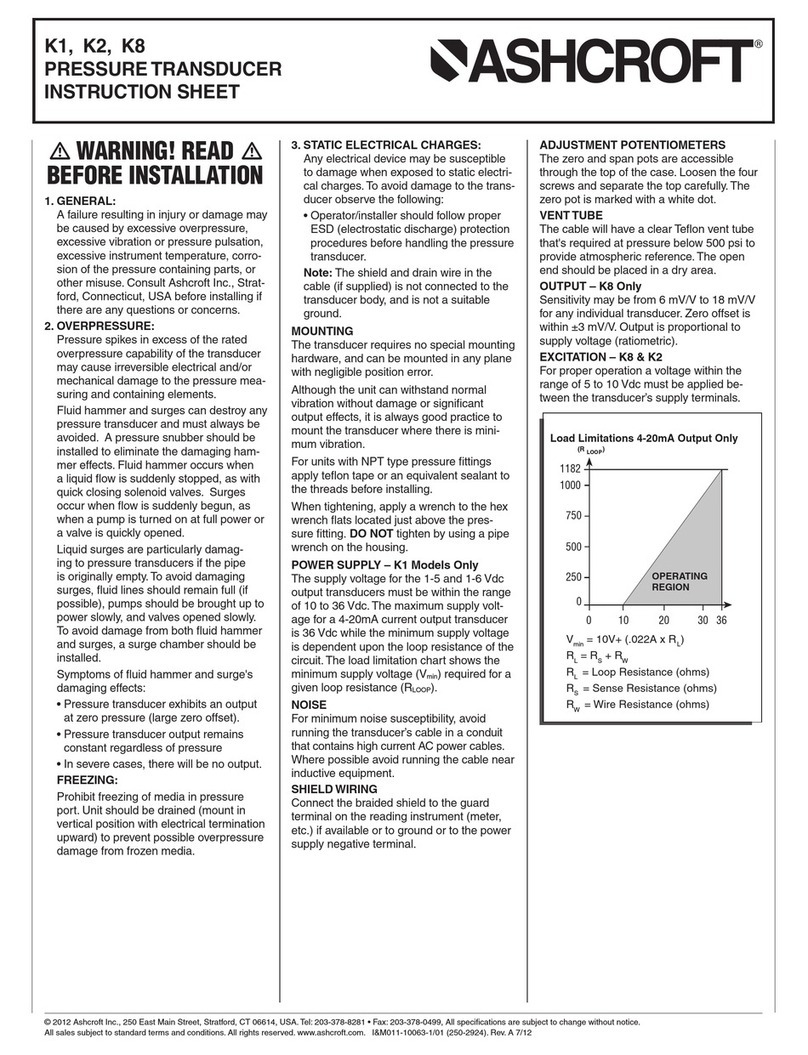

3 Wire System (Voltage Output)

(dc Voltmeter)

Receiver

Power Source

12 to 24 Vdc

Common Black

Output (+) White

ZL91

+

−

(dc Ammeter)

Receiver

24 Vdc ±10%

+ Red

– White

ZL91

+

+−

−

2 Wire System (Current Output)